Adjustable joint heat regenerative system

A regenerative system and adjustable technology, applied in the directions of preheating, feedwater heaters, lighting and heating equipment, etc., can solve the problems of large extraction steam superheat, large heat exchange temperature difference of feedwater heaters, and increased irreversible losses, etc. Boiler combustion performance is improved, drying output is achieved, and economy is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

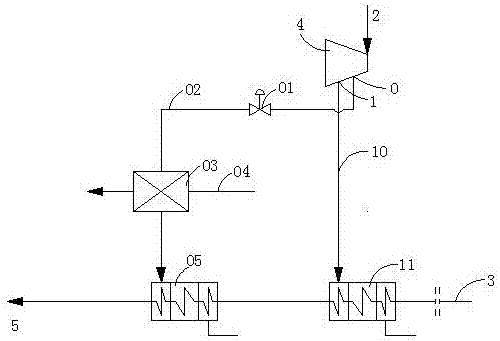

[0033] figure 1 It is a schematic diagram of the system of the specific embodiment 1 of the present invention. In this embodiment, on the basis of the conventional final steam extraction port 1, the final steam extraction 10 and the final feed water heater 11, an additional adjustable post on the high pressure cylinder 4 is added. Final stage extraction port 0, additional adjustable rear final stage extraction pipe 02, additional adjustable rear final stage feed water heater 05, additional adjustable rear final stage extraction pipe heat exchanger 03 and additional adjustable rear end Stage extraction regulating valve 01.

[0034] The additional adjustable final stage feed water heater 05 is connected to the heat exchanger 03 and the additional adjustable rear final stage extraction port 0 on the high pressure cylinder 4 through the additional adjustable rear final stage extraction pipe 02, and is connected to the conventional final stage Feedwater heaters 11 are connected in...

Embodiment 2

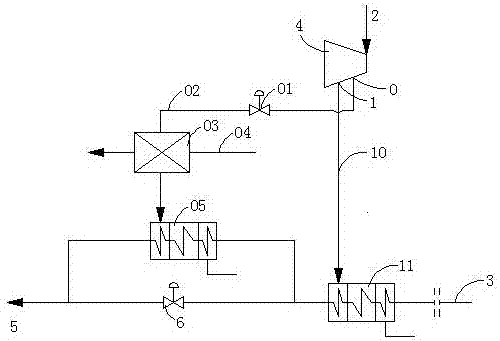

[0041] figure 2 It is a schematic diagram of the system of the specific embodiment 2 of the present invention. In this embodiment, on the basis of the conventional final steam extraction port 1, the final steam extraction 10 and the final feed water heater 11, an additional adjustable post on the high pressure cylinder 4 is added. Final steam extraction port 0, additional adjustable rear final steam extraction pipeline 02, additional adjustable rear final feed water heater 05, water side regulating valve 6, additional adjustable rear final steam extraction pipeline heat exchanger 03 And an additional adjustable post-final extraction steam regulating valve 01.

[0042] The additional adjustable final stage feed water heater 05 is connected to the heat exchanger 03 and the additional adjustable rear final stage extraction port 0 on the high pressure cylinder 4 through the additional adjustable rear final stage extraction pipe 02, and is connected to the conventional final stage...

Embodiment 3

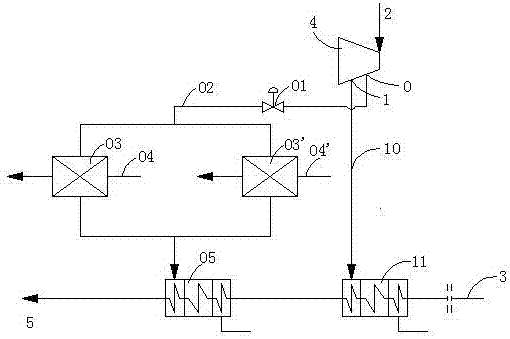

[0046] image 3 It is a schematic diagram of the system of the specific embodiment 2 of the present invention. In this embodiment, on the basis of the conventional final steam extraction port 1, the final steam extraction 10 and the final feed water heater 11, an additional adjustable post on the high pressure cylinder 4 is added. Final steam extraction port 0, additional adjustable final steam extraction pipeline 02, additional adjustable final feed water heater 05, additional adjustable final heat exchangers 03 and 03' on the final steam extraction pipeline, and additional Adjustable final stage extraction steam regulating valve 01.

[0047] The additional adjustable final stage feed water heater 05 is connected to the heat exchanger 03 and the additional adjustable rear final stage extraction port 0 on the high pressure cylinder 4 through the additional adjustable rear final stage extraction pipe 02, and is connected to the conventional final stage Feedwater heaters 11 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com