Connecting mechanism based on petroleum pipeline welding joint crack detection positioning

A technology for welding joints and oil pipelines, applied in the direction of pipes/pipe joints/fittings, special pipes, pipe components, etc., can solve the problems of reduced stability, device movement and shaking, poor use range, etc., to expand the bending range and facilitate disassembly. The effect of installing and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

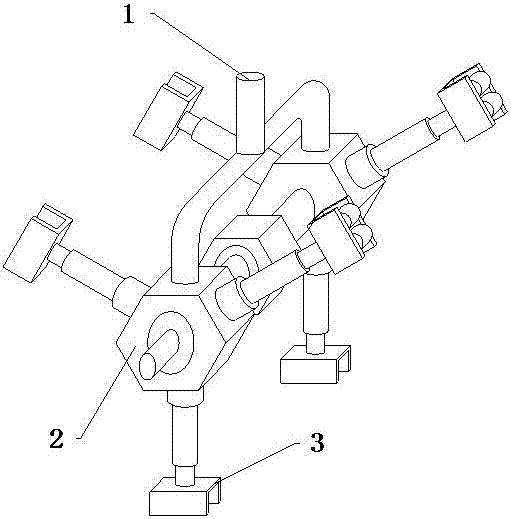

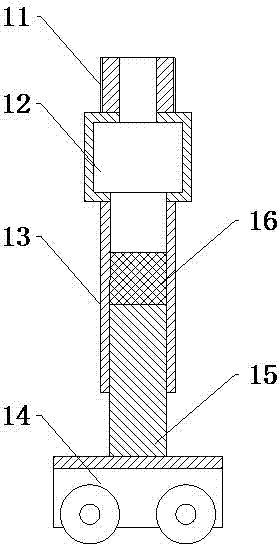

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: a connection mechanism based on flaw detection and positioning of welded joints of petroleum pipelines, including a flexible hose 1, a connection assembly 2 and a moving assembly 3, the lower end of the flexible hose 1 is provided with a connection assembly 2, connected The outer end of the component 2 is equipped with a mobile component 3 .

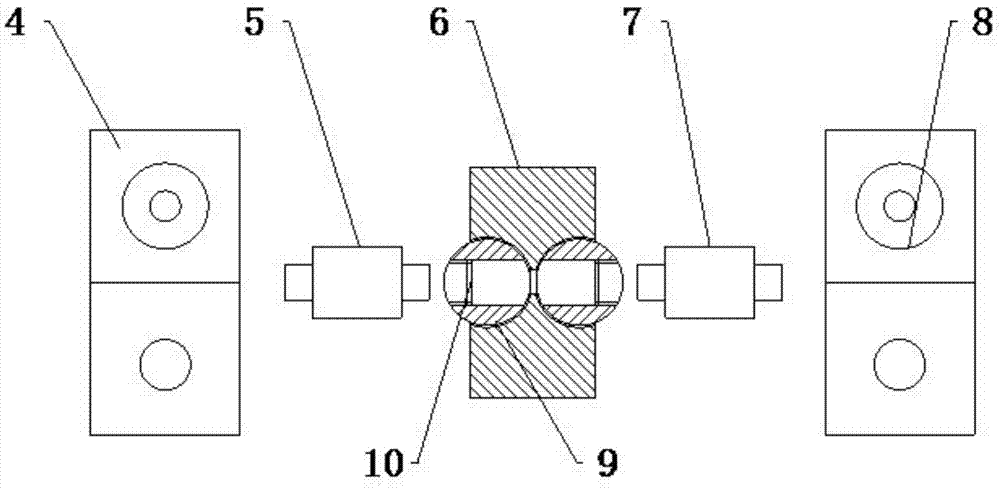

[0021] The connection assembly 2 includes a front hexagonal connection terminal 4, a connector one 5, a housing 6, a connector two 7, a rear hexagonal connection terminal 8, a ball head 9 and a through hole 10, and the front hexagonal connection terminal 4 rear end A connector 5 is provided, the rear end of the connector 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com