A high temperature superconducting cable structure

A cable structure, high-temperature superconducting technology, applied in the direction of superconducting devices, superconducting/high-conducting conductors, superconducting elements, etc., can solve the problem that the stress cannot be released, and the superconducting tape and the cooling medium cannot be fully contacted and other problems to achieve the effects of not being prone to local quenching, good heat dissipation, and increasing the bending range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

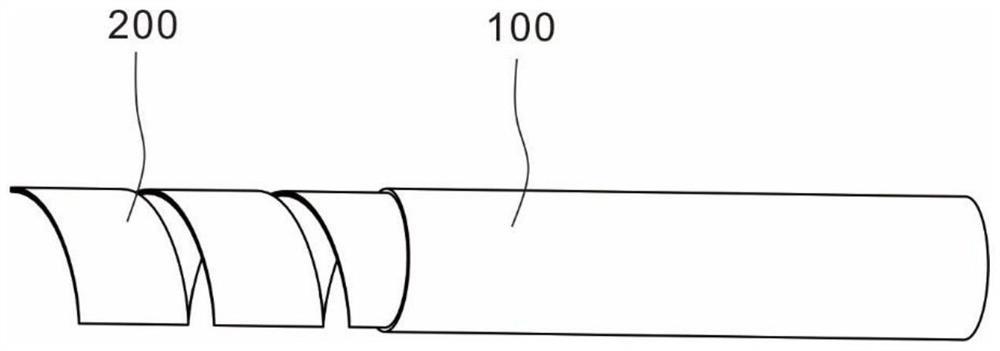

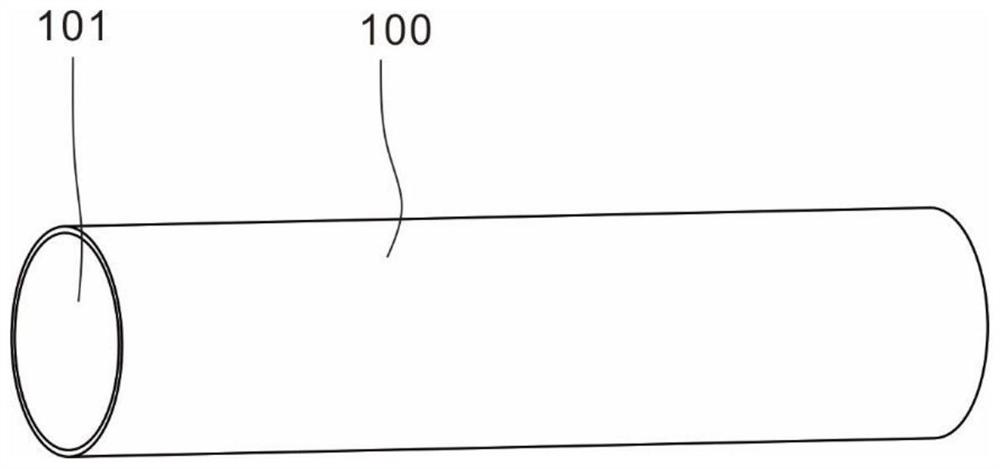

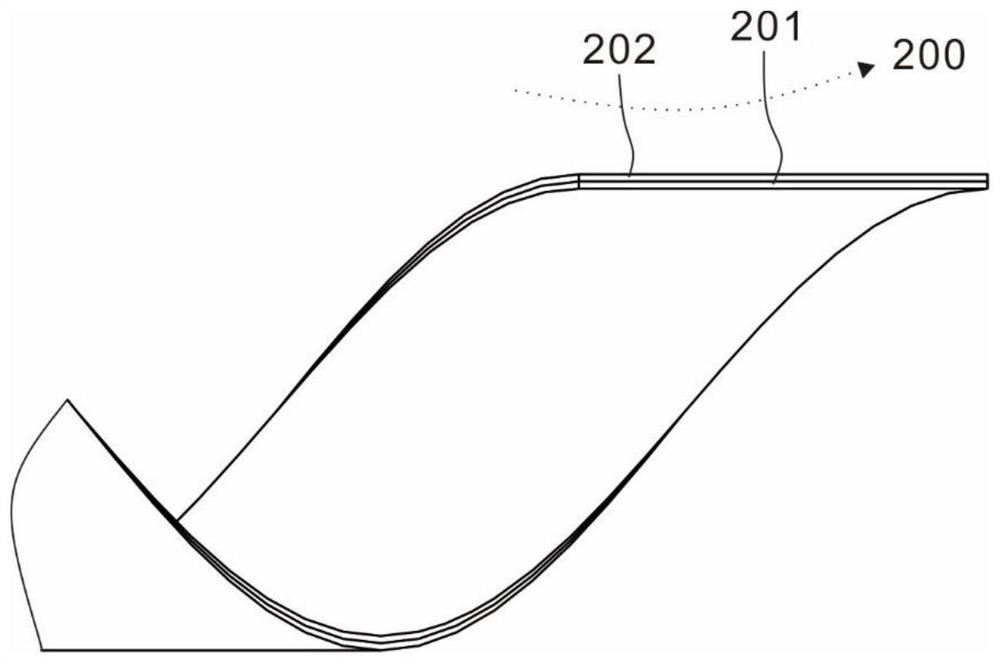

[0038] This embodiment provides a high temperature superconducting cable structure, such as figure 1 As shown, in this embodiment, the high-temperature superconducting cable structure includes a support unit 100 and a superconducting tape unit 200. The support unit 100 is the shell of the high-temperature superconducting cable structure, and is used as a supporting part in the high-temperature superconducting cable structure. The conduction strip unit 200 is a conductive part attached to the inner wall of the supporting unit 100 .

[0039] Preferably, the supporting unit 100 is the shell of the high-temperature superconducting cable structure, and an accommodating space 101 is arranged in the middle. Initially, there is a circular inner core, and the superconducting tape unit 200 is spirally wound around this circular inner core. Above, the accommodating space 101 of the support unit 100 is slightly larger than this structure, and the support unit 100 is placed on this structu...

Embodiment 2

[0043] This embodiment provides a high temperature superconducting cable structure, such as Figure 1-5 , in this embodiment, the high-temperature superconducting cable structure includes a filling unit 300 and a bonding unit 400, the filling unit 300 is a low-temperature liquid filled after the superconducting tape unit 200 is released from stress, and it is not limited to liquid nitrogen, liquid helium, liquid Hydrogen, fixed nitrogen, or other cryogenic liquids to enable the use of superconducting cable structures.

[0044] The bonding unit 400 is a filling material arranged between the superconducting tape unit 200 and the supporting unit 100 , in order to enable the superconducting tape unit 200 and the supporting unit 100 to be closely attached together.

[0045]Preferably, the supporting unit 100 is the shell of the high-temperature superconducting cable structure, and an accommodating space 101 is arranged in the middle. Initially, there is a circular inner core, and t...

Embodiment 3

[0050] This embodiment provides a high temperature superconducting cable structure, such as Figure 1-11 , in this embodiment, the support unit 100 is the shell of the high-temperature superconducting cable structure, and an accommodating space 101 is arranged in the middle. Initially, there is a circular inner core, and the superconducting tape unit 200 is wound in a spiral shape. On the circular inner core, the accommodating space 101 of the support unit 100 is slightly larger than this structure, and the support unit 100 is placed on this structure to evenly release the stress of the superconducting tape unit 200, so that its diameter can be controlled and uniformly expanded. After the angle increases to a specified value, the circular inner core is removed, and the superconducting tape unit 200 is wound and attached to the inner wall of the support unit 100 at this time.

[0051] The filling unit 300 is a cryogenic liquid filled after the superconducting tape unit 200 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com