Method for obtaining high-yield curdlan bacterial strain through high-flux screening

A high-throughput, high-yield technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of time-consuming, labor-intensive, limited number of screening, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Correlation between different concentrations of curdlan gum standard substance and aniline blue color development in embodiment 1

[0067] Prepare 2mg / ml curdlan standard substance, dilute to different concentrations, successively 0, 0.1, 0.2, 0.4, 0.6, 0.8, 1, 1.2, 1.4, 1.6, 1.8, 2mg / ml, dilute the different concentrations Standard samples of curdlan gum and 2 mg / ml aniline blue solution with pH 7.0, shake and mix well, react at room temperature for 1-2 hours in the dark, and measure with a microplate reader at 590 nm. The results are shown in Table 1 and figure 1 shown by figure 1 It can be seen that there is a good correlation between curdlan content and absorbance value, R 2 is 0.9891.

[0068] Table 1 Different concentrations of standard substances and aniline blue color reaction measurement results

[0069]

Embodiment 2

[0070] The measurement of embodiment 2 aniline blue assay method coefficient of variation in 96 orifice plates

[0071] Select a strain and spread it on the plate, after 3 days of culture, pick a single colony into a 96-well plate, and use the above method for fermentation and measurement. The results are as follows: image 3 shown by image 3 It can be seen that the coefficient of variation of the 96-well plate fermentation is 13.8%, which is within a reasonable range (less than 20%), and there is no edge well effect. Therefore, positive mutants whose absorbance value measured by a microplate reader is higher than the coefficient of variation can be selected for re-screening.

Embodiment 3

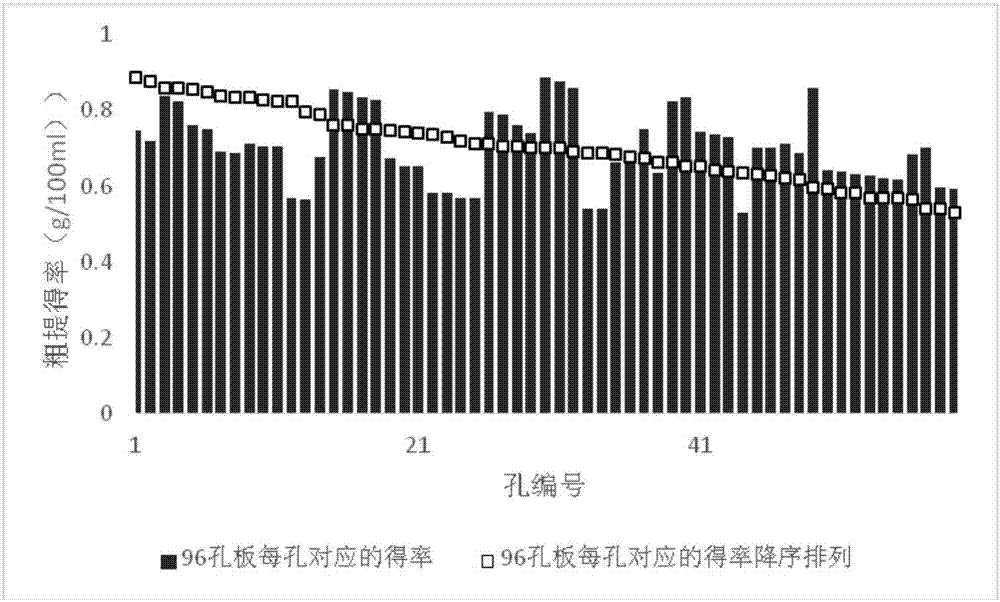

[0072] Application of embodiment 3 aniline blue color development method in NTG mutagenesis screening

[0073] Carry out NTG mutagenesis using the method in step (1) above, pick 40 strains and carry out the 96-well plate primary screening described in step (2) for fermentation, and simultaneously carry out the shake flask verification fermentation described in step (4) After the experiment, the correlation between the two was determined after the fermentation. Experimental results such as figure 2 shown by figure 2 It can be seen that using the aniline blue chromogenic method established above to screen the mutagenized strains on a 96-well plate, and at the same time as a shake flask control, the results show that there is a good correlation between the chromogenic method and the shake flask assay. Therefore, the method established by the present invention can be well used for the screening of high-yield curdlan gum strains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com