A wetting reversal agent for improving the depressurization and injection enhancement effect of low-permeability reservoir water injection wells and its preparation method

A low-permeability reservoir and wettability reversal technology, applied in the field of wettability reversal agent and its preparation, can solve the problems of reduced crude oil production, low water injection efficiency in low-permeability oilfields, and reduced final output rate of oilfields, etc., to improve The effect of reducing pressure and increasing injection, improving ultimate oil recovery, and improving mutual solubility stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

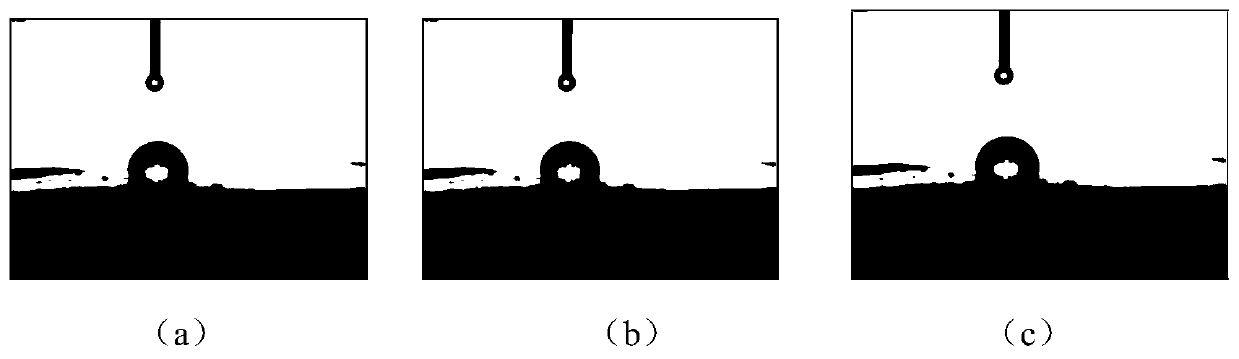

Image

Examples

Embodiment 1

[0050] Example 1: Measures for pressure reduction and injection enhancement in water injection wells

[0051] In a low-permeability oilfield, the average porosity of oil layers is 10.6%, and the average permeability is 0.85×10 -3 μm 2 , the reservoir has oil wettability and small pore throat, and the injected water (SO 4 2- Content 2800mg / L) and reservoir water (Ba 2+ / Sr 2+ content of 3300mg / L) is incompatible, and Ba(Sr)SO 4 Scaling and clogging mainly lead to an increase in water injection pressure, a decrease in water injection volume or even no water injection, which affects the normal water injection development of the oil field.

[0052] Water injection well Yuan*-51, composite perforation + high-energy gas fracturing injection in May 2012, water injection pressure was 15.5Mpa and water injection volume was 15m in June 2012 3 / d, to meet the water injection allocation requirements, the water injection pressure of the well continued to increase after injection, unt...

Embodiment 2

[0054] Example 2: Measures for pressure reduction and injection enhancement in water injection wells

[0055] In a low-permeability oilfield, the average porosity of oil layers is 9.36%, and the average permeability is 0.64×10 -3 μm 2 , the reservoir has oil wettability and small pore throat, and the injected water (SO 4 2- Content 2550mg / L) and reservoir water (Ba 2+ \Sr 2+ content of 3400mg / L) is incompatible, and Ba(Sr)SO 4 Scaling and clogging mainly lead to an increase in water injection pressure, a decrease in water injection volume or even no water injection, which affects the normal water injection development of the oil field.

[0056] Water injection well Yuan*-48, composite perforation + high-energy gas fracturing injection in December 2010, water injection pressure 15.1Mpa, water injection volume 15m in January 2011 3 / d, to meet the water injection allocation requirements, the water injection pressure of the well continued to increase after injection, until ...

Embodiment 3

[0059] Example 3: Measures for removing scale and plugging in oil wells

[0060] Well Xinyuan*-7 was completed on November 2, 2001, and put into production after deflagration and fracturing of oil layers. In December 2001, the production fluid was 9.59m 3 / d, the oil production is 3.62t / d, and the water content is 55.1%. During the production process, due to the corrosion of the casing in the upper water layer of the oil well, the casing is broken and leaked, and the water produced in the upper formation is poured back into the oil layer, resulting in a decrease in the oil production of the oil well. In July 2006, the production fluid was 17.05m 3 / d, the oil production is 2.55t / d, and the water content is 82.2%. After isolation by the oil production packer, in April 2012, the fluid production was 2.08m 3 / d, water 0.43t / d, water content 75.0%.

[0061] In June 2012, the technological measure of "cleaning and descaling" was applied, that is, the wetting reversal agent pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com