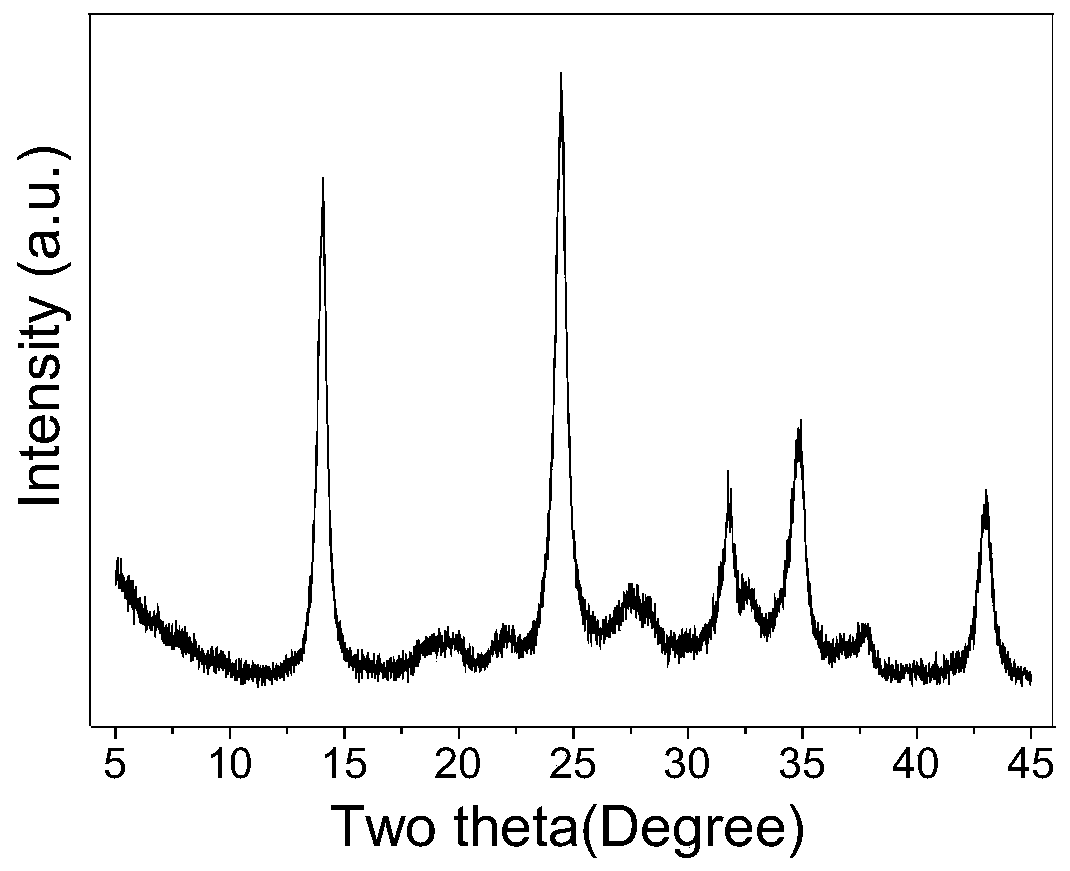

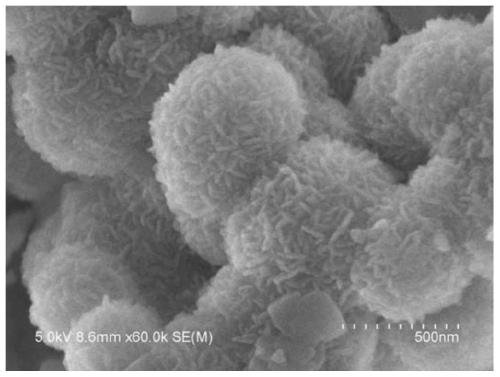

A kind of preparation method of petal-shaped sodalite at room temperature

A technology of room temperature and flower petals, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, silicate, etc., can solve the problems of high cost, high energy consumption, high temperature, etc., and achieve low cost, good crystallinity, and consumption short-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of petal-shaped sodalite under room temperature of the present invention comprises the following steps:

[0031] (1) Weigh 2.21g of sodium aluminate and 4.56g of sodium hydroxide into the beaker, then add 20.50g of deionized water, and heat and stir to completely dissolve the raw materials to make solution A;

[0032] (2) Weigh 5.68g of sodium silicate nonahydrate and add it to another beaker, then add 25.12g of deionized water, and heat and stir to completely dissolve the raw materials to make solution B;

[0033] (3) Slowly add solution B to solution A, and stir rapidly to make it evenly mixed to form a silica-alumina gel mixture;

[0034] (4) Transfer the silica-alumina gel mixture to a polytetrafluoroethylene reaction kettle, place it in a water bath, set the temperature of the water bath to 25°C, and crystallize for 10 hours;

[0035] (5) After the reaction is completed, take out the reaction kettle, filter the crystallized reaction mixture ...

Embodiment 2

[0037] The preparation method of petal-shaped sodalite under room temperature of the present invention comprises the following steps:

[0038] (1) Weigh 3.76g of aluminum sulfate and 4.78g of sodium hydroxide into the beaker, then add 20.50g of deionized water, and heat and stir to completely dissolve the raw materials to make solution A;

[0039] (2) Weigh 5.39g of sodium silicate nonahydrate and add it to another beaker, then add 20.85g of deionized water, and heat and stir to completely dissolve the raw materials to make solution B;

[0040] (3) Add solution B slowly to solution A, and stir rapidly to make it mix evenly to form a silica-alumina gel mixture;

[0041] (4) Transfer the silica-alumina gel mixture to a polytetrafluoroethylene reaction kettle, place it in a water bath, set the temperature of the water bath to 25°C, and crystallize for 10 hours;

[0042] (5) After the reaction is completed, take out the reaction kettle, filter the reaction mixture with suction, a...

Embodiment 3

[0044] The preparation method of petal-shaped sodalite under room temperature of the present invention comprises the following steps:

[0045] (1) Weigh 1.72g of aluminum hydroxide and 4.78g of sodium hydroxide into a beaker, then add 20.50g of deionized water, and heat and stir to completely dissolve the raw materials to make solution A;

[0046] (2) Weigh 5.68g of sodium silicate nonahydrate and add it to another beaker, then add 24.68g of deionized water, and heat and stir to completely dissolve the raw materials to make solution B;

[0047] (3) Add solution B slowly to solution A, and stir rapidly to make it mix evenly to form a silica-alumina gel mixture;

[0048] (4) Transfer the silica-alumina gel mixture to a polytetrafluoroethylene reaction kettle, place it in a water bath, set the temperature of the water bath to 25°C, and crystallize for 10 hours;

[0049] (5) After the reaction is completed, take out the reaction kettle, filter the reaction mixture with suction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com