Test packing machine of ID coil and test packing technology of ID coil

A packaging machine and coil technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as backward testing and packaging equipment technology, improve testing efficiency and quality, achieve automation, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

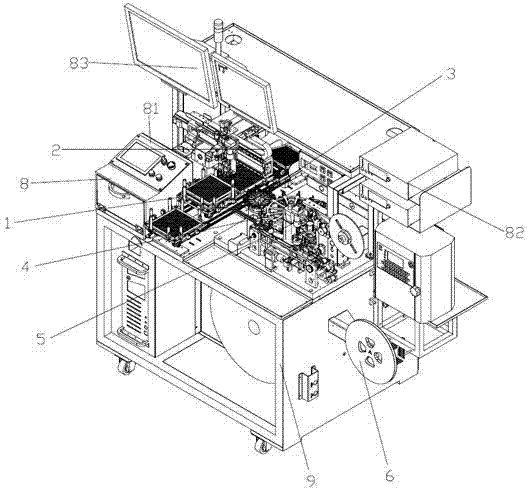

[0040] like figure 1 As shown, a test packaging machine for ID coils, the test packaging machine includes a frame and a control device 8 installed on the frame, and a feeding mechanism 1 electrically connected to the control device 8, a material taking mechanism 2, Transition mechanism 3, detection mechanism 4, packaging mechanism 5 and take-up mechanism 6, described control device 8 comprises main control box 81, display screen 83 and tester 82, and PLC control system is installed in main control box 81, through human The machine combination and the PLC control the operation of each mechanism. By programming the PLC, the electrical components of each part of the mechanism are controlled to operate according to the design requirements. There are three kinds of buttons to carry out production operation and control, which is easy to operate, and the machine running status and fault problems are clearly reflected.

[0041] like Figure 2-3 As shown, the feeding mechanism 1 main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com