Non-inductive inspection method and system based on multi-window integrated lifting mechanism

A lifting mechanism, multi-window technology, applied in CCTV systems, control/adjustment systems, sensing radiation of moving objects, etc., can solve the problems of long time, low entry and exit efficiency, and cumbersome processes for passengers getting on and off the bus and customs clearance, etc. Achieve the effect of reducing failure rate, optimizing line length, and realizing inspection automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a non-inductive inspection method based on a multi-window integrated lifting mechanism. The method includes: setting a left acquisition module and a right acquisition module on the driveway to collect information from the personnel in the driver's seat and passenger seat in the vehicle; Among them, the left acquisition module and the right acquisition module are fixed on the same support frame, and realize horizontal or vertical movement under the control of the multi-axis motion control device to collect information from the personnel close to the driver's seat and the passenger seat respectively. Among them, the support frame is erected on both sides of the driveway, and the left acquisition module and the right acquisition module correspond to the personnel in the driver's seat and passenger seat in the car respectively. The multi-axis motion control device is used to control the left acquisition module and the right acquisition module to perf...

Embodiment 2

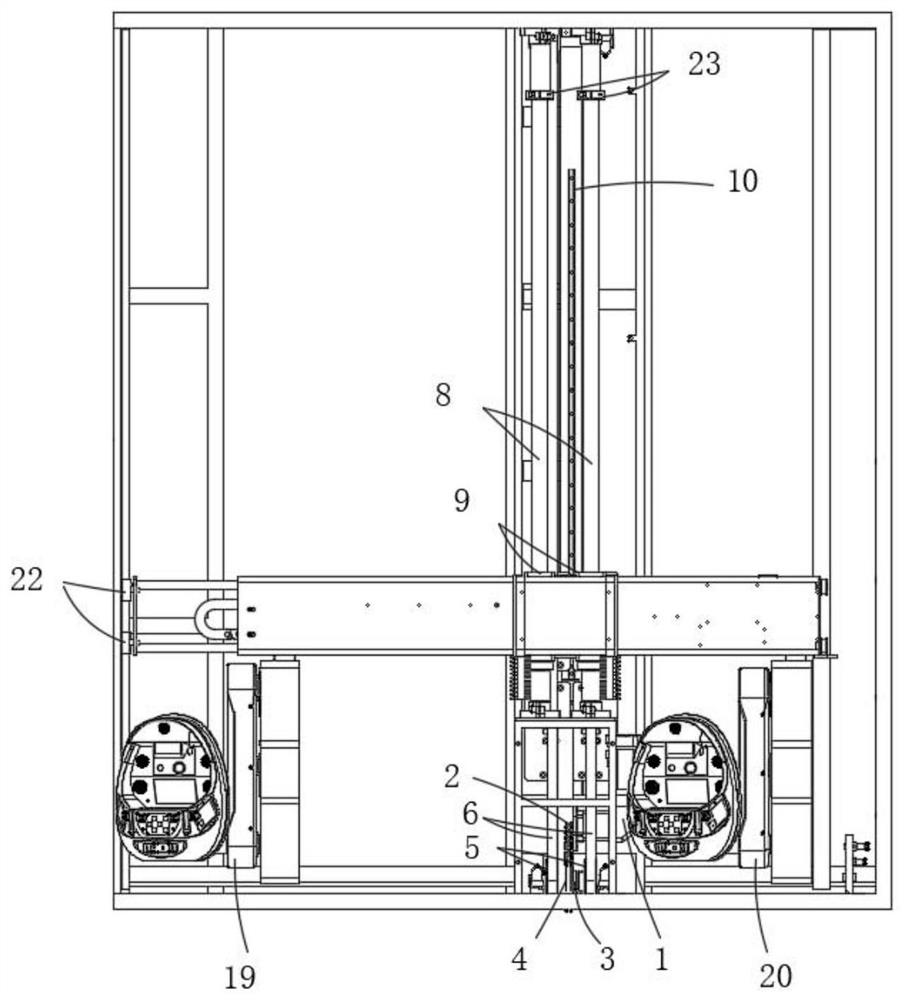

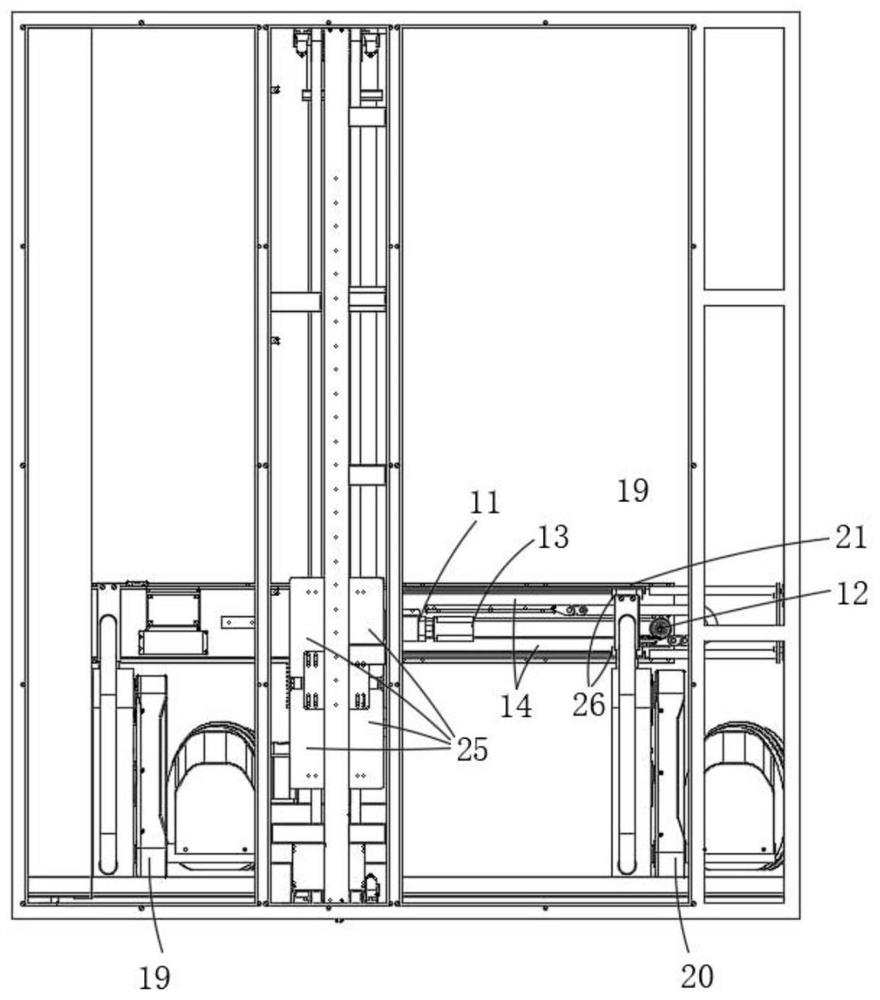

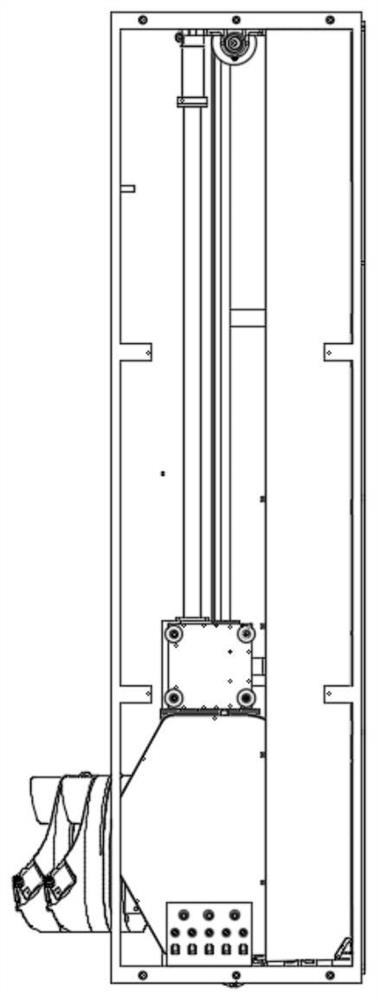

[0047] This embodiment provides a non-inductive inspection system based on a multi-window integrated lifting mechanism. The non-inductive inspection system includes a lane for vehicles to pass, a left acquisition module for collecting information on the personnel in the driver's seat and passenger seat in the car, and The right acquisition module, the multi-axis motion control device controlling the movement of the left acquisition module and the right acquisition module, and the support frame arranged on both sides of the lane and used to support and fix the left acquisition module, the right acquisition module and the multi-axis motion control device , the support frame is erected across the driveway. The multi-axis motion control device includes a multi-window integrated lifting mechanism, a motor and a motor control circuit for driving the multi-window integrated lifting mechanism, and a positioning module for locating people in the vehicle; the left acquisition module and ...

Embodiment 3

[0057] This embodiment provides a control system for a non-inductive inspection system based on a multi-window integrated lifting mechanism, which includes a joint inspection entrance subsystem, a joint collection and inspection integrated cabinet system, a joint inspection exit subsystem, and a background data server system. The joint inspection entrance subsystem, the joint collection and inspection integrated cabinet system, and the joint inspection exit subsystem all establish communication connections with the background data server system through wired or wireless methods; the control system includes the following control methods:

[0058] The joint inspection entrance subsystem detects that the vehicle enters the lane, collects vehicle information and sends it to the multi-axis motion control device;

[0059] The positioning information of the positioning module of the multi-axis motion control device is used to control the information collection module on the multi-window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com