One-side welding with back formation welding method for large double-layer cylinder of nuclear power station

A technology of single-sided welding and double-sided welding, which is applied in welding equipment, arc welding equipment, applications, etc., can solve the problems of high equipment cost, low welding efficiency, increased cost, etc., to reduce welding heat input and improve welding efficiency. Efficiency, beautiful weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The material of the large cylinder of the nuclear power plant is Q345B, and the thickness of the steel plate in some areas is 20mm.

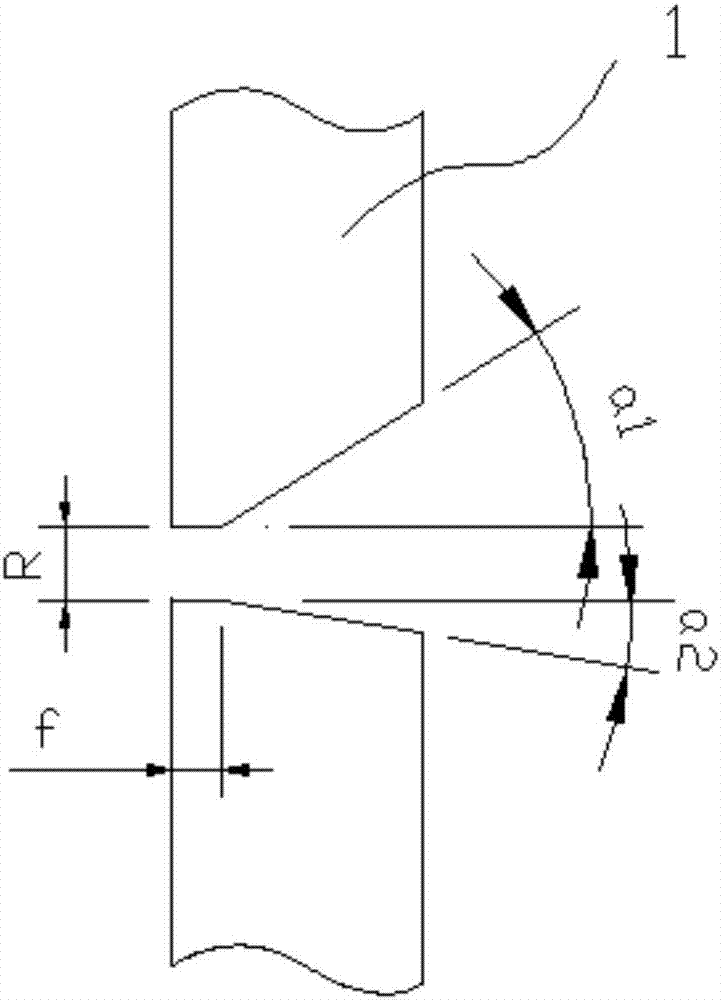

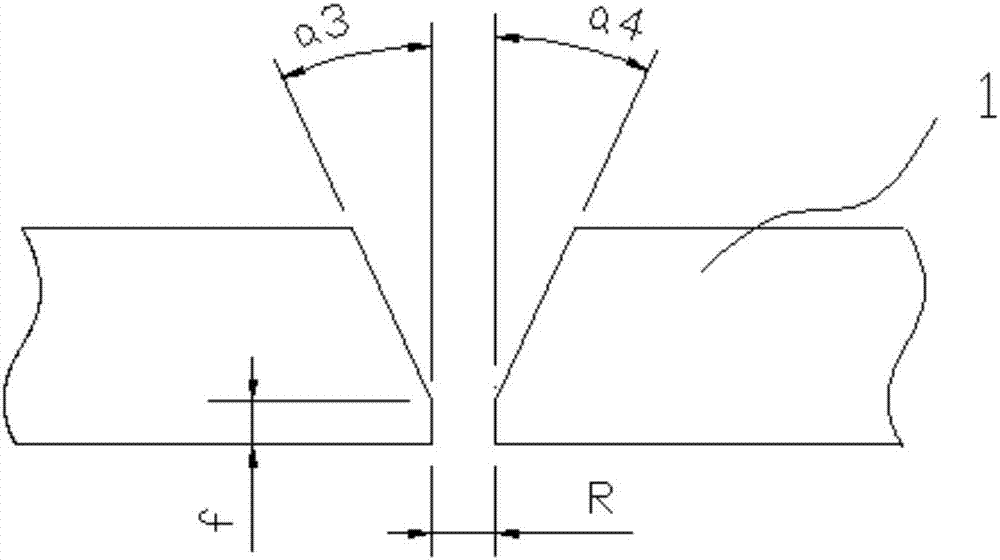

[0031] The welding groove form is a V-shaped groove, in which the groove angle of the transverse joint is 45±5°, the groove angle a1 of the upper steel plate of the group pair is 35±2.5°, and the groove angle a2 of the lower steel plate is 10±2.5°. The pair gap R is 3~7mm, the blunt edge f is 0~2mm; the vertical seam groove angle is 50±5°, the steel plate groove angles a3 and a4 on both sides of the group pair are 25±2.5°, and the group pair gap R is 3-7mm, the blunt edge f is 0-2mm.

[0032] The welding equipment is an inverter DC melting electrode gas shielded welding machine, the polarity of the welding power supply is DC reverse connection, the welding shielding gas is 82% argon + 18% carbon dioxide (the percentage is the volume ratio), and the gas flow rate is 22L / min. For ER50-6 welding wire with a diameter of 1.2mm, the dry elonga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dry elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com