Preparation method and dye degrading method of calcium alginate coated zero-valent iron

A calcium alginate, coated technology, applied in the field of water pollution control, can solve the problems of high cost, easy passivation, difficult recovery, etc., and achieve the effects of easy recovery, enhanced reaction performance, and enhanced dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

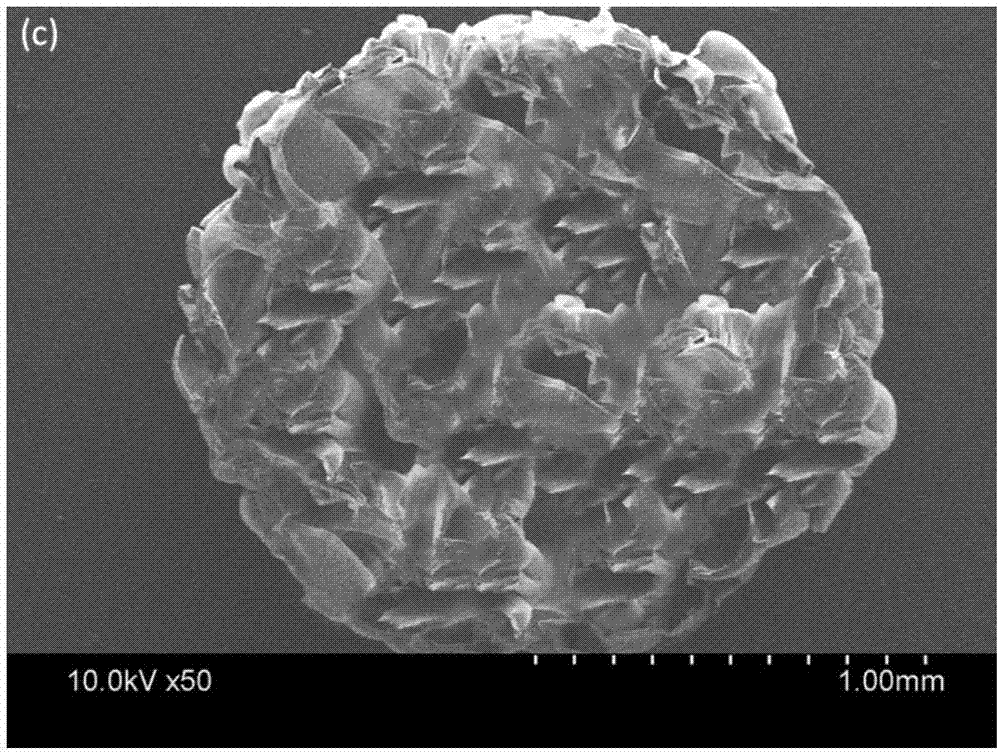

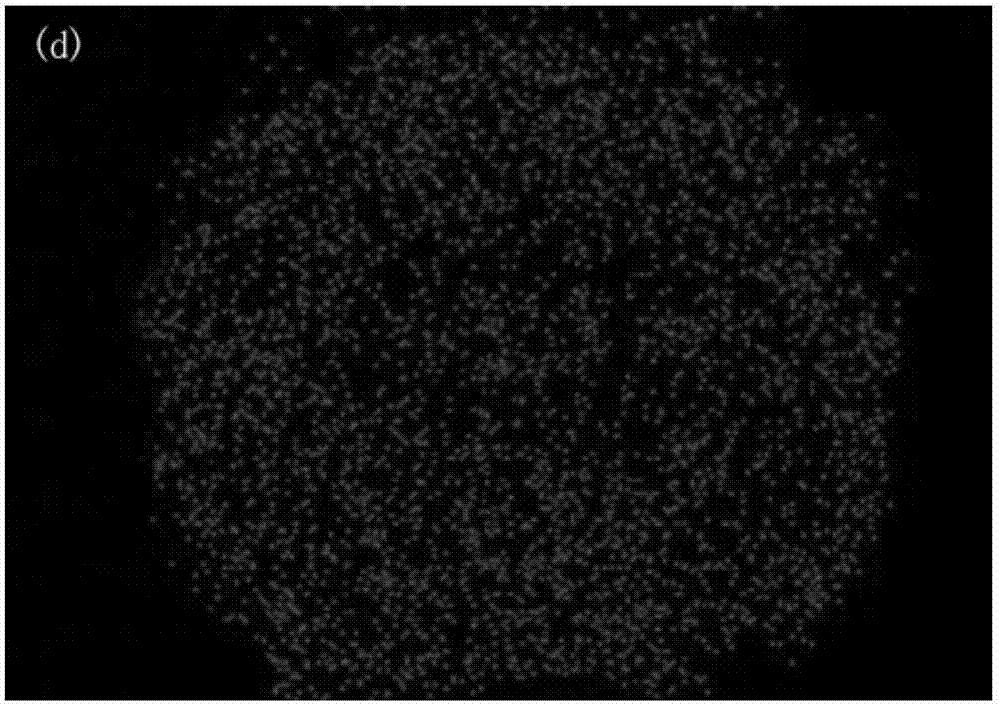

[0045] A preparation method of calcium alginate-coated zero-valent iron, comprising the following steps

[0046] 1) Prepare a sodium alginate aqueous solution with a mass concentration of 2.5%, stir magnetically until the solution is completely clear and transparent, and let it stand for defoaming;

[0047] 2) Add 5 mL of prepared sodium alginate aqueous solution to 20 mL of 0.3 M CaCl at a rate of 1 mL / min. 2 and 0.15M FeCl 3 in the mixed solution; oscillating coordination for 12 hours; after the coordination is completed, wash repeatedly with ultrapure water for 3 times, that is, calcium alginate-coated iron ion gel balls are prepared;

[0048] 3) The prepared calcium alginate-coated iron ion gel balls were placed in a container bottle, and 15 mL of 0.2 M potassium borohydride (KBH 4 ) aqueous solution, after shaking and reacting for 30 minutes, washed repeatedly 3 times with ethanol aqueous solution (V alcohol: V water = 1:1), that is, calcium alginate-coated zero-valent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

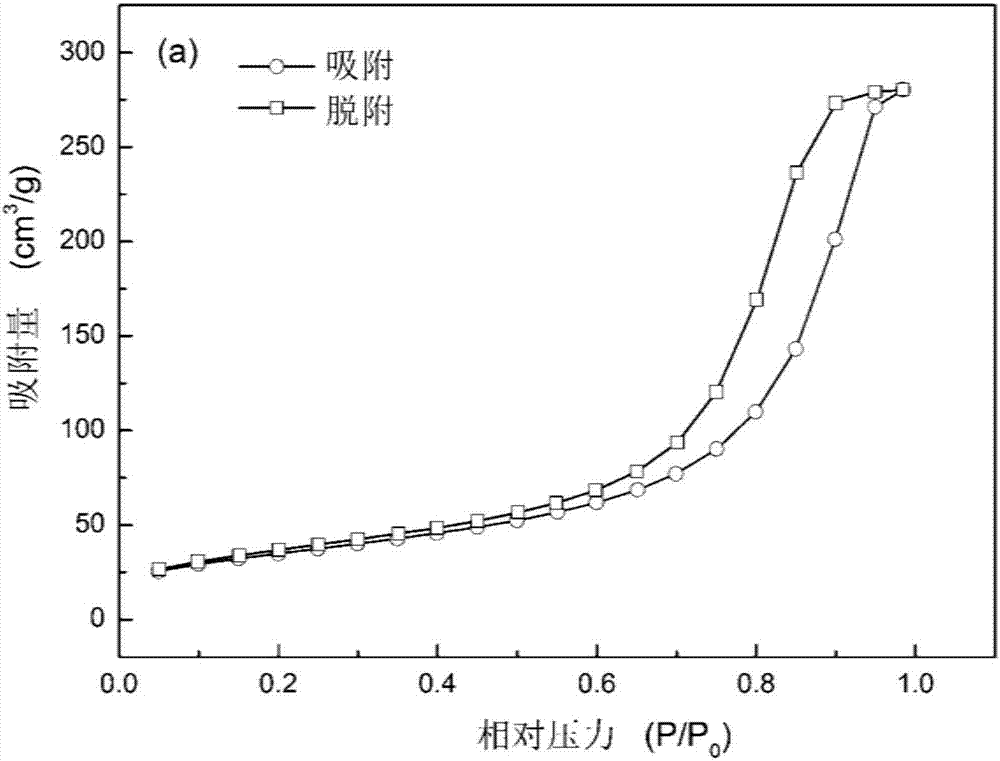

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com