Preparation method of chitosan-based organic-inorganic hybridized porous thin film

A technology of porous film and chitosan, which is applied in the direction of inorganic chemistry, chemical instruments and methods, membrane technology, etc., to achieve the effect of enhancing the adsorption effect, increasing the specific surface area, and reducing the number of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of chitosan-based organic-inorganic hybrid porous film, the specific preparation steps are as follows:

[0029] ①, preparation of coating solution

[0030] Weigh 20 g of chitosan (CS), and dissolve it in 1000 mL of 2% acetic acid solution by volume. Then weigh 4g of NaCl powder and add it into the solution, stir to dissolve, let stand to defoam, and obtain A liquid.

[0031] Measure 25mL of γ-diethylenetriaminepropylmethyldimethoxysilane (KH-603 for short), add it to 100mL of absolute ethanol, and stir evenly to obtain liquid B.

[0032] Slowly add liquid B into liquid A dropwise, stir and react at room temperature for 4 hours, and let stand to defoam to obtain a coating liquid.

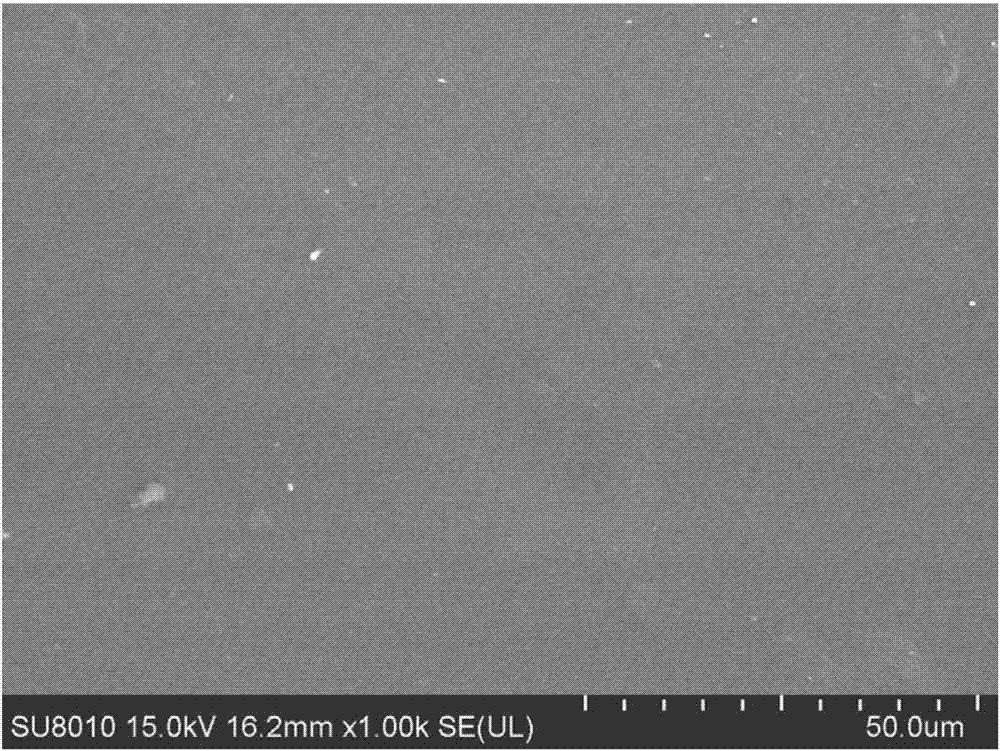

[0033] ②. Preparation of hybrid membrane

[0034] Absorb the solution after standing, pour it into a clean and dry glass compartment, cast it into a film, and let it dry naturally to obtain a hybrid film.

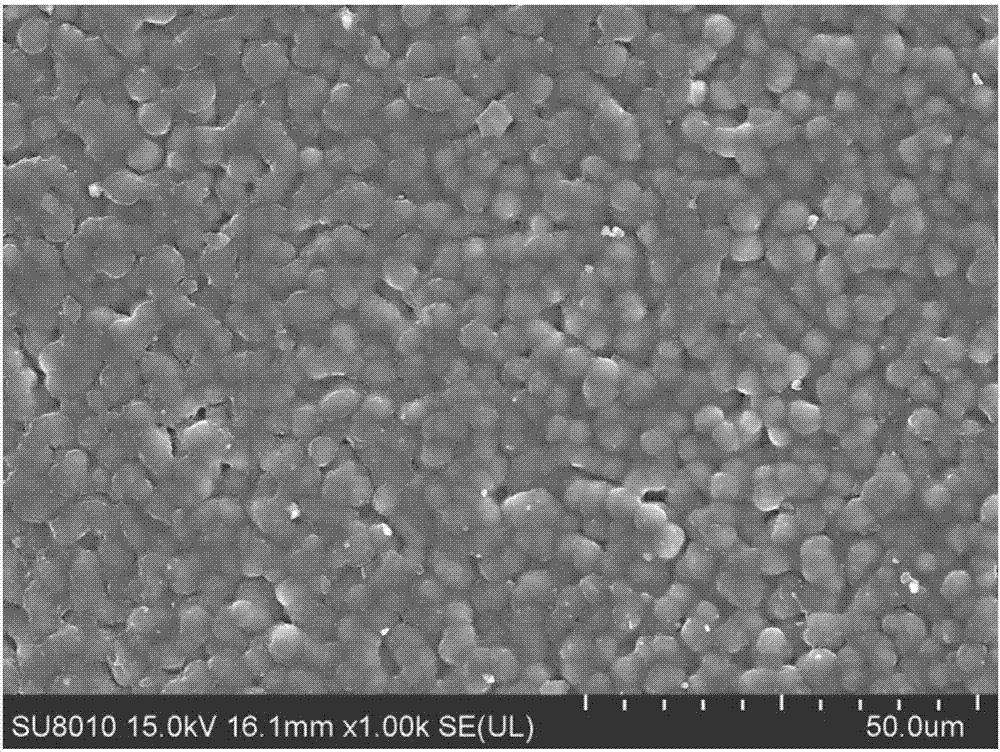

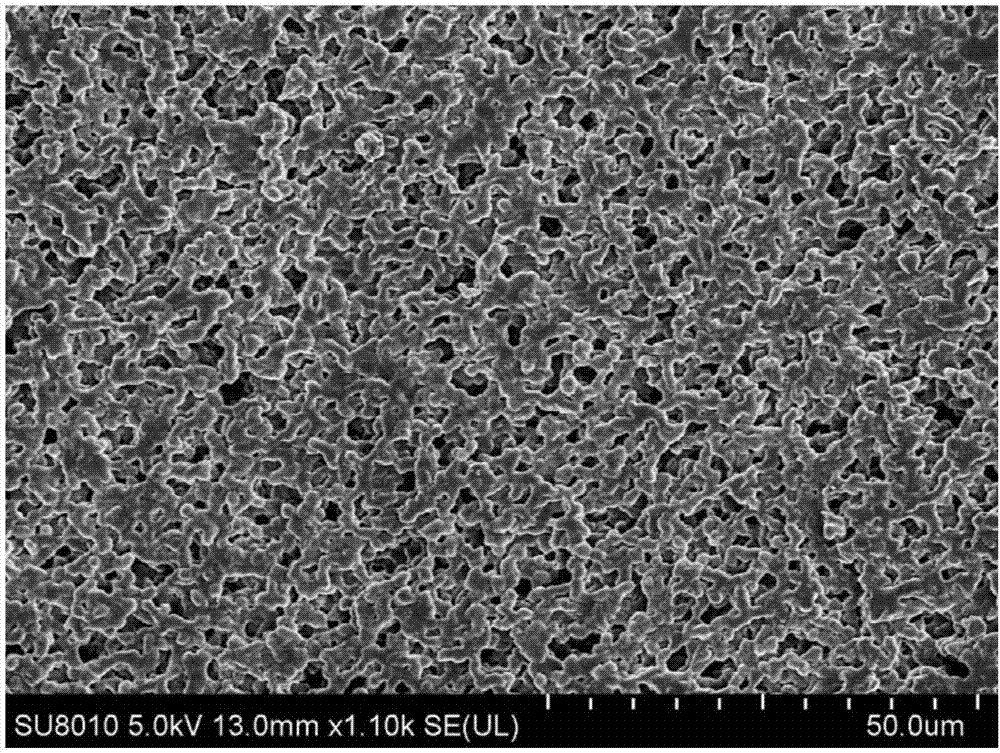

[0035] ③. Preparation of organic-inorganic hybrid porous membr...

Embodiment 2

[0040] A preparation method of chitosan-based organic-inorganic hybrid porous film, the specific preparation steps are as follows:

[0041] ①, preparation of coating solution

[0042] Weigh 20 g of chitosan (CS), and dissolve it in 1000 mL of 2% acetic acid solution by volume. Then weigh 4g of NaCl powder and add it into the solution, stir to dissolve, let stand to defoam, and obtain A liquid.

[0043] Measure 25 mL of N-aminoethyl-γ-aminopropyltriethoxysilane (KH-791 for short), add it to 100 mL of absolute ethanol, and stir evenly to obtain liquid B.

[0044] Slowly add liquid B into liquid A dropwise, stir and react at room temperature for 4 hours, and let stand to defoam to obtain a coating liquid.

[0045] ②. Preparation of hybrid membrane

[0046] Absorb the solution after standing, pour it into a clean and dry glass compartment, cast it into a film, and let it dry naturally to obtain a hybrid film.

[0047] ③. Preparation of organic-inorganic hybrid porous membrane ...

Embodiment 3

[0051] A preparation method of chitosan-based organic-inorganic hybrid porous film, the specific preparation steps are as follows:

[0052] ①, preparation of coating solution

[0053] Weigh 20 g of chitosan (CS), and dissolve it in 1000 mL of 2% acetic acid solution by volume. Then weigh 4g of NaCl powder and add it into the solution, stir to dissolve, let stand to defoam, and obtain A liquid.

[0054] Measure 25mL of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane (abbreviated as KH-792), add it to 100mL of absolute ethanol, stir well, and obtain liquid B.

[0055] Slowly add liquid B into liquid A dropwise, stir and react at room temperature for 4 hours, and let stand to defoam to obtain a coating liquid.

[0056] ②. Preparation of hybrid membrane

[0057] Absorb the solution after standing, pour it into a clean and dry glass compartment, cast it into a film, and let it dry naturally to obtain a hybrid film.

[0058] ③. Preparation of organic-inorganic hybrid porous membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com