Rice steaming box capable of recycling steam heat

A technology of heat recovery and rice steamer, which is applied to steam cooking utensils, heating devices, cooking utensils, etc., can solve the problem that the residual heat of the furnace at the bottom of the pot cannot be effectively utilized, the thermal efficiency conduction conversion rate is low, and the heat of the furnace problems such as low utilization rate, to achieve the effect of improving energy utilization efficiency, improving energy utilization rate, reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

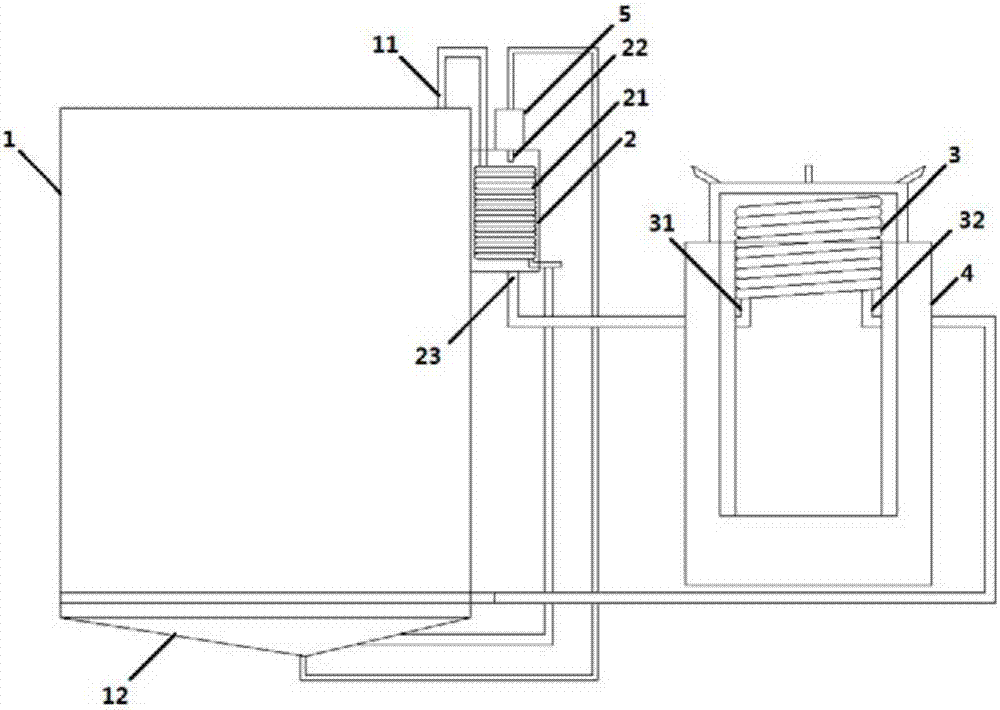

[0016] A rice steaming box for steam heat recovery, such as figure 1 As shown, it includes a rice steaming box 1 and a water tank 2. The water tank 2 is provided with a heat exchange pipe 21, and one end of the heat exchange pipe 21 is connected with the steam exhaust pipe 11 of the rice steaming box 1, and the water tank 2 is provided with a water inlet pipe. 22 and the water outlet pipe 23, the water inlet pipe 22 is connected with the external water supply pipe, and the water outlet pipe 23 is connected with the water inlet 31 of the steam generator 3 of the rice steaming box 1.

[0017] Further, the steam generating device 3 is a spiral annular heating tube arranged at the mouth of the stove 4, the bottom end of the heating tube is a water inlet 31, the upper end of the heating tube is a steam port 32, and the steam port 32 An extension pipe is provided at the place, and the extension pipe is bent to the inner side of the heating pipe and then bent downwards, extending to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com