Micro-resonant cavity LED chip with substrate removed through chemical erosion and preparation method thereof

An LED chip, chemical corrosion technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of chamber pollution of epitaxial growth equipment, reduce the quality of GaN thin films, etc., achieve high corrosion selection ratio, reduce equivalent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

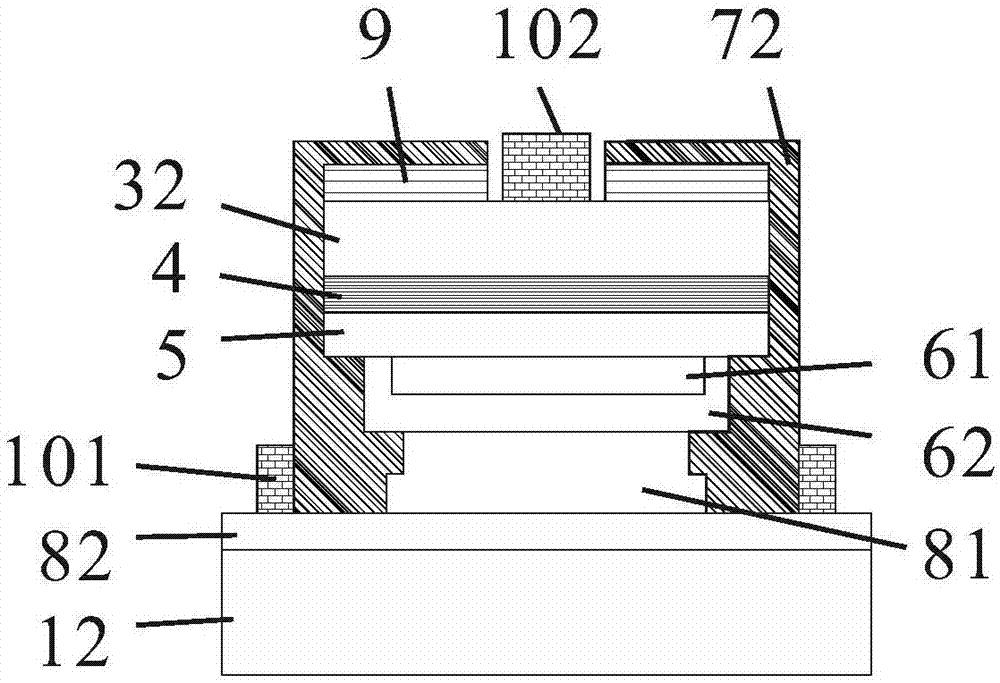

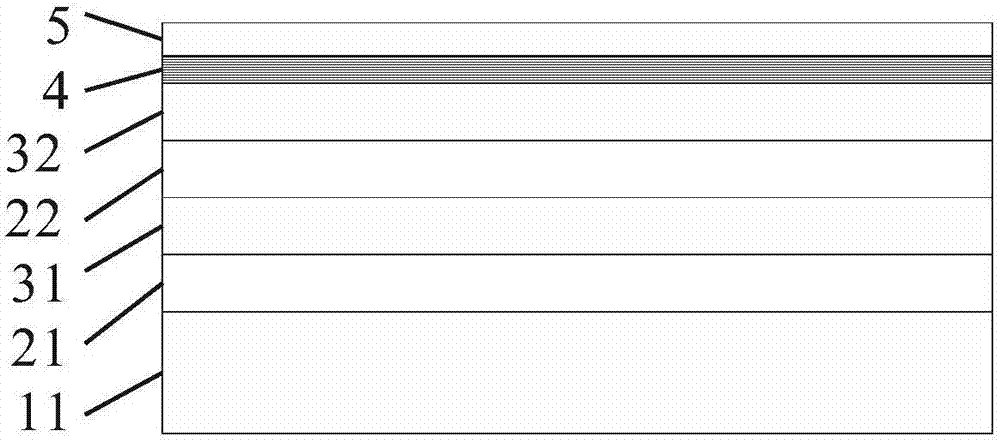

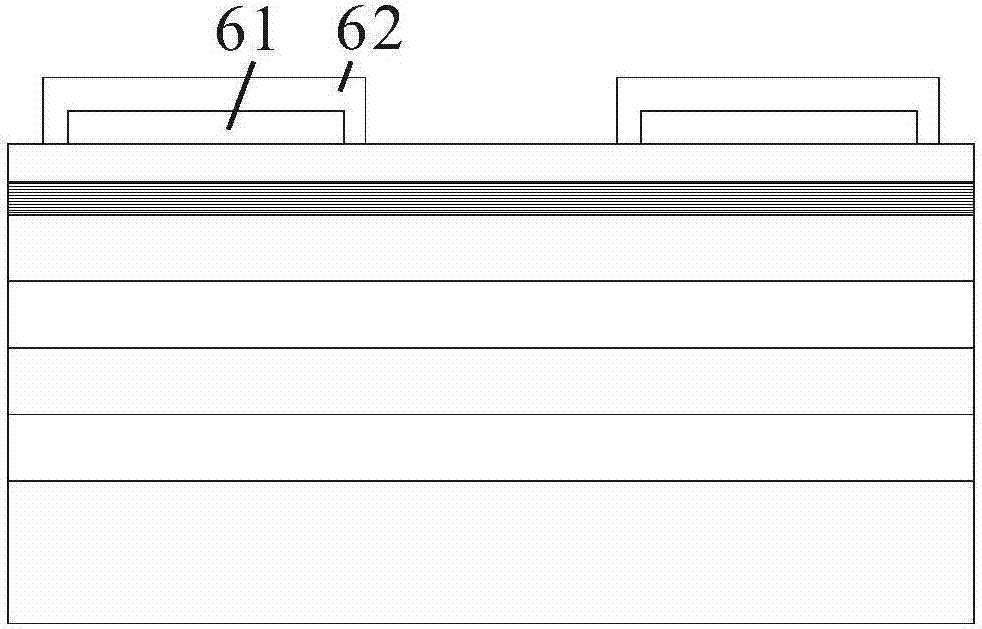

[0058] Such as figure 1 Shown is a schematic cross-sectional view of a micro-sized resonant cavity LED chip with chemical etching and peeling off the substrate in a specific embodiment of the present invention. The chip is a disc with a diameter of 100 μm; Sheet heat conduction substrate 12, second bonding Cr / Ti / Au metal layer 82, first bonding Cr / Ti / Au metal layer 81, metal protective layer 62 of reflective electrode, Ni / Ag / Ni reflective electrode 61, p- GaN layer 5, quantum well layer 4, n-GaN layer 32 and SiO 2 / Ti 3 o 5 Medium DBR 9;

[0059] The first bonding Cr / Ti / Au metal layer 81, metal protection layer 62 of reflective electrode, Ni / Ag / Ni reflective electrode 61, p-GaN layer 5, quantum well layer 4, n-GaN layer 32 and SiO 2 / Ti 3 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com