Method for preparing hollow structure tungsten oxide nano-wires through graphene oxide in-situ growth method

A nano-tungsten oxide, in-situ growth technology, applied in the field of nano-materials, can solve the problems of high conditions and high energy consumption, achieve high purity, simple process, and improve the effect of nano-scale uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

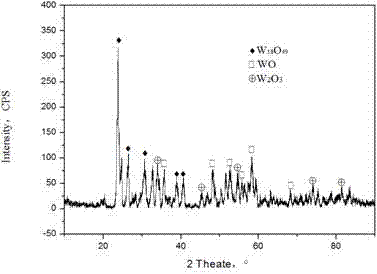

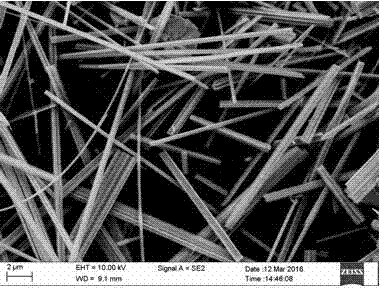

[0027] The present invention provides a method for preparing hollow structure nano tungsten oxide wire by in-situ growth of graphene oxide. The method includes the steps of adding a certain amount of graphite powder to concentrated H2SO4 (12mL), K2S2O8 (2.5g) and P2O5 (2.5g). In the solution composed of ), react at 80°C for 4.5 hours. Then it was cooled to room temperature and 0.5 L of deionized water was added. And dry at room temperature. Add this pre-oxidized graphite powder to 150mL of concentrated H2SO4, keep the environment at 0°C with an ice water bath, gradually add 15g KMnO4, and keep the temperature not exceeding 20°C, and stir at 35°C for 2 hours after the addition. Then 250 mL of deionized water was added and stirred for 2 hours. Then add 0.7 L of deionized water, then add 30 mL of 30% H2O2, dry at room temperature, and then dialyze in a dialysis bag for 1 week to remove impurities. Finally, after vacuum filtration and drying at room temperature, graphene oxide i...

Embodiment 2

[0033] On the basis of the above example, the steps of this example are: adding a certain amount of graphite powder to a solution consisting of concentrated H2SO4 (12mL), K2S2O8 (2.5g) and P2O5 (2.5g), and reacting at 80°C for 4.5 hour. Then it was cooled to room temperature and 0.5 L of deionized water was added. And dry at room temperature. Add this pre-oxidized graphite powder to 150mL of concentrated H2SO4, keep the environment at 0°C with an ice water bath, gradually add 15g KMnO4, and keep the temperature not exceeding 20°C, and stir at 35°C for 2 hours after the addition. Then 250 mL of deionized water was added and stirred for 2 hours. Then add 0.7 L of deionized water, then add 30 mL of 30% H2O2, dry at room temperature, and then dialyze in a dialysis bag for 1 week to remove impurities. Finally, after vacuum filtration and drying at room temperature, graphene oxide is obtained.

[0034] Weigh 2g of graphene oxide, add 1000g of absolute ethanol, stir and mix evenly, ...

Embodiment 3

[0036] On the basis of the above example, the steps of this example are: adding a certain amount of graphite powder to a solution consisting of concentrated H2SO4 (12mL), K2S2O8 (2.5g) and P2O5 (2.5g), and reacting at 80°C for 4.5 hour. Then it was cooled to room temperature and 0.5 L of deionized water was added. And dry at room temperature. Add this pre-oxidized graphite powder to 150mL of concentrated H2SO4, keep the environment at 0°C with an ice water bath, gradually add 15g KMnO4, and keep the temperature not exceeding 20°C, and stir at 35°C for 2 hours after the addition. Then 250 mL of deionized water was added and stirred for 2 hours. Then add 0.7 L of deionized water, then add 30 mL of 30% H2O2, dry at room temperature, and then dialyze in a dialysis bag for 1 week to remove impurities. Finally, after vacuum filtration and drying at room temperature, graphene oxide is obtained.

[0037] Weigh 3g of graphene oxide, add 1000g of absolute ethanol, stir and mix evenly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com