Straw artificial board and preparation method thereof

A technology for wood-based panels and straws, which is applied in the field of aldehyde-free, non-toxic and fire-resistant straw-based wood-based panels and their preparation fields, can solve problems such as harm to health, and achieve the effects of cost reduction, high hardness and enhanced performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

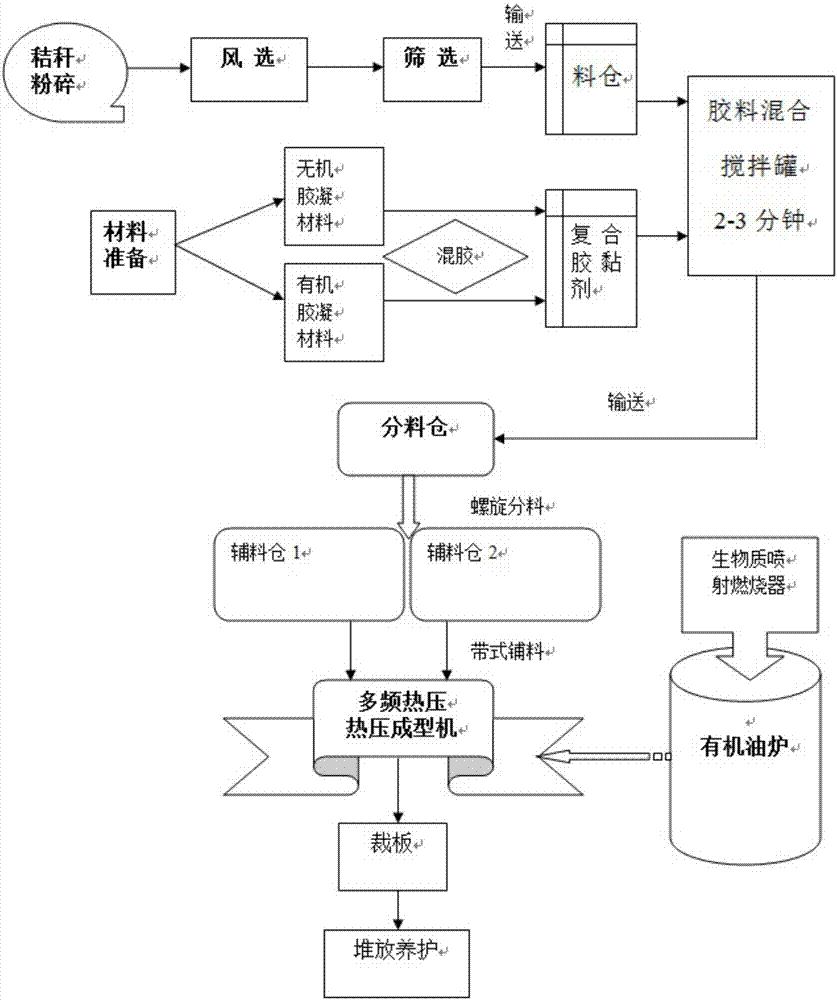

Method used

Image

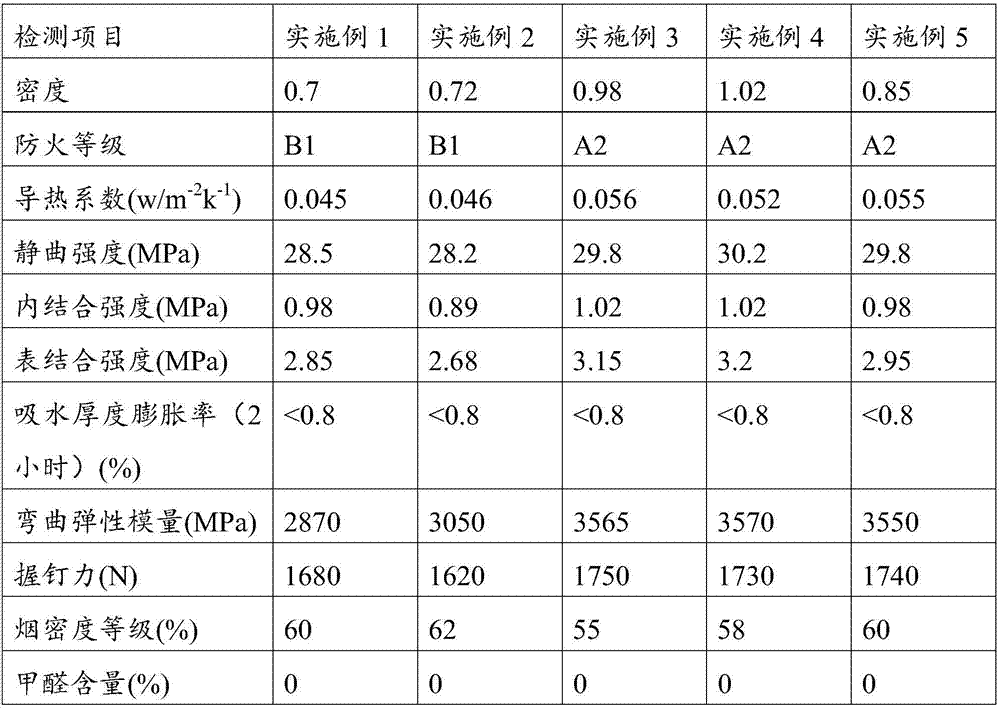

Examples

Embodiment 1

[0039] A straw-based panel, the straw-based panel is prepared by a preparation method comprising the following steps:

[0040] (1), the preparation of inorganic gelling material: with the MgO of 30%, the MgSO of 40% 4 , 20% MgCO 3 , 1% active silicon, 6% Al 2 SiO 5 and 3% red clay were added to warm water at 50°C, and stirred evenly to obtain an inorganic gelling material;

[0041] (2), preparation of organic gelling material: bean gum and polyamide epichlorohydrin are mixed, add water, stir, obtain organic gelling material; The weight ratio of described bean gum and polyamide epichlorohydrin is 5:1;

[0042] (3), mix the inorganic gelling material obtained in step (1) and the organic gelling material obtained in step (2) according to a weight ratio of 1:1, and use a colloid mill to grind the mixture while adding deionized water, When the solid content in the mixture is 35%, and the mixture is sticky and paste-like, with a delicate hand feeling and no sticky feeling when ...

Embodiment 2

[0046] A straw-based panel, the straw-based panel is prepared by a preparation method comprising the following steps:

[0047] (1), the preparation of inorganic gelling material: with the MgO of 50%, the MgSO of 20% 4 , 15% MgCO 3 , 3% active silicon, 10% Al 2 SiO 5 and 2% red clay were added to warm water at 30°C, and stirred evenly to obtain an inorganic gelling material;

[0048] (2), preparation of organic gelling material: bean gum and polyamide epichlorohydrin are mixed, add water, stir, obtain organic gelling material; The weight ratio of described bean gum and polyamide epichlorohydrin is 10:1;

[0049] (3), mix the inorganic gelling material obtained in step (1) and the organic gelling material obtained in step (2) according to a weight ratio of 5:1, and use a colloid mill to grind the mixture while adding deionized water, When the solid content in the mixture is 40%, and the mixture is sticky and paste-like, with a delicate hand feeling and no sticky feeling whe...

Embodiment 3

[0053] A straw-based panel, the straw-based panel is prepared by a preparation method comprising the following steps:

[0054] (1), the preparation of inorganic gelling material: with the MgO of 50%, the MgSO of 30% 4 , 10% MgCO 3 , 2% active silicon, 7% Al 2 SiO 5 and 1% red clay were added to warm water at 40°C, and stirred evenly to obtain an inorganic gelling material;

[0055] (2), preparation of organic gelling material: bean gum and polyamide epichlorohydrin are mixed, add water, stir, obtain organic gelling material; The weight ratio of described bean gum and polyamide epichlorohydrin is 9:1;

[0056] (3), mix the inorganic gelling material obtained in step (1) and the organic gelling material obtained in step (2) according to a weight ratio of 2:1, and use a colloid mill to grind the mixture while adding deionized water, When the solid content in the mixture is 50%, and the mixture is sticky and paste-like, with a delicate hand feeling and no sticky feeling when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com