Dry red wine and preparation method thereof

A technology of dry red wine and wine, applied in the field of wine making, to achieve a strong sense of structure, elegant fruity and wine aroma, and the effect of improving color and aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

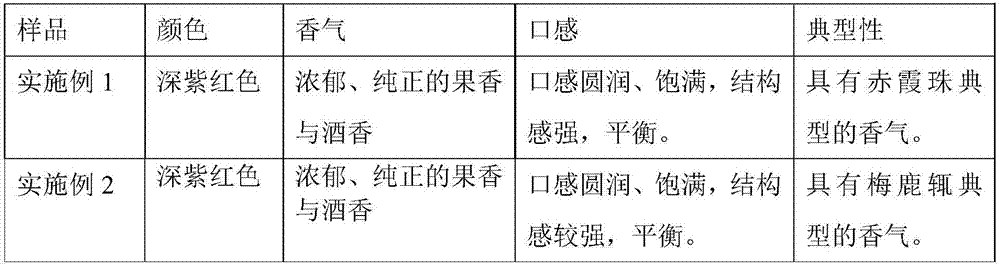

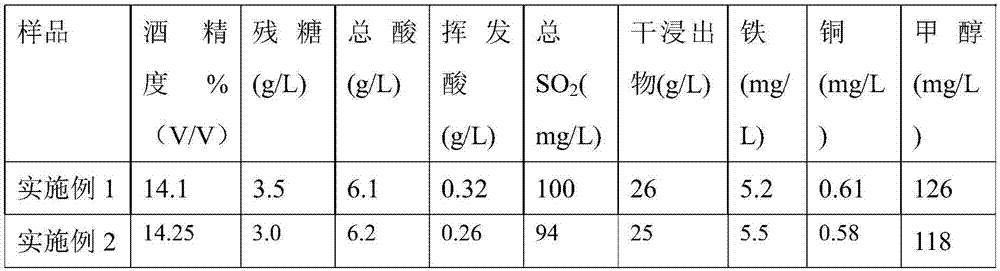

Embodiment 1

[0024] Harvest Cabernet Sauvignon grapes with good maturity, and measure the sugar content and total acid equivalent index of the fruit before harvesting. The sugar content of Cabernet Sauvignon fruit is 245g / L (based on glucose), and the total acid is 6.5g / L ( Calculated by tartaric acid), pH 3.33, measured density 1.110 (relative to water density); immediately after harvesting, enter the cold storage (-10°C) to freeze, and after complete freezing (the fruit becomes hard), the grapes are destemmed and crushed, and put into the tank while uniformly adding SO 2 40mg / L, when the measured temperature of the grape must is about -2°C, add dry ice 10kg / m 3 (grape must), sealed fermentation tank; 1 closed cycle per day, supplemented with 1kg / m 3 (grape must) dry ice; control the temperature of the grape juice below 6°C (if it is higher than 6°C, use refrigeration equipment to cool down to this temperature), after 5 days, taste the grape juice, the color, aroma and taste meet the re...

Embodiment 2

[0026] Merlot grapes with good maturity were harvested, and the sugar content and total acid equivalent indicators of the fruit were measured before harvesting. The sugar content of Cabernet Sauvignon fruit was 250g / L (calculated as glucose), and the total acid was 6.3g / L ( Calculated by tartaric acid), pH 3.41, measured density 1.115 (relative to water density); immediately after harvesting, enter the cold storage (-10°C) to freeze, and after complete freezing (the fruit becomes hard), the grapes are destemmed and crushed, and put into the tank while uniformly adding SO 2 40mg / L, when the measured temperature of the grape juice is about -2.5℃, add dry ice 10kg / m 3 (grape must), airtight; once a day in an airtight cycle, supplemented with 1kg / m 3 (grape must) dry ice; control the temperature of the grape juice below 6°C (if it is higher than 6°C, use refrigeration equipment to cool down to this temperature), after 4 days, taste the grape juice, the color, aroma and taste mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com