Building waste recycled concrete and preparation method thereof

A technology for recycling concrete and construction waste, applied in the field of building materials, can solve the problems of land occupation, resource waste, and environmental pollution, and achieve the effects of good toughness, low cost, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

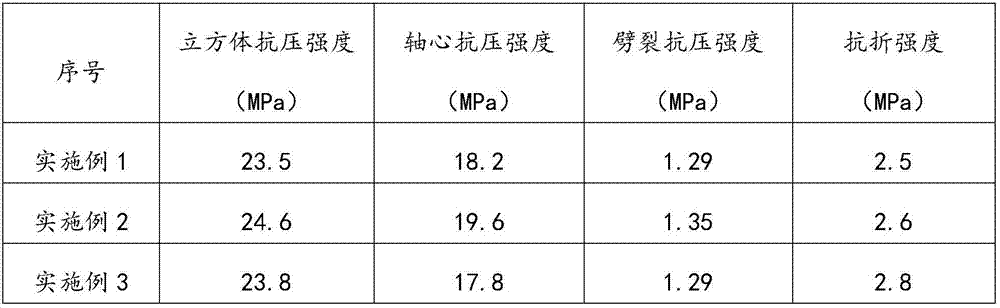

Examples

Embodiment 1

[0022] The construction waste recycled concrete in this embodiment is made of the following raw materials: 50 kg of construction waste recycled aggregate, 20 kg of reinforcing agent, 5 kg of water reducing agent, 20 kg of curing agent, 5 kg of mineral powder, 90 kg of Portland cement cement, and 100 kg of water and polyamide 20kg, wherein, the construction waste regenerated aggregate refers to the construction waste with a particle size of 2-10mm obtained after crushing, sieving, and removing foreign matter, and the reinforcing agent is silica fume powder and redispersible Latex powder is the mixture of 1:3 by mass ratio, and described curing agent is made of 12% calcium sulfate, 12% sodium chloride, 12% calcium chloride, 12% ammonium bicarbonate, 12% potassium carbonate and 40% water by mass percentage Prepared by mixing.

[0023] The preparation method of above-mentioned construction waste recycled concrete comprises the following steps:

[0024] (1) Take the following raw ...

Embodiment 2

[0027] The construction waste recycled concrete of this embodiment is made of the following raw materials: 60 kg of construction waste recycled aggregate, 15 kg of reinforcing agent, 10 kg of water reducing agent, 15 kg of curing agent, 10 kg of mineral powder, 60 kg of Portland cement cement, and 125 kg of water and polyamide 15kg, wherein, the construction waste regenerated aggregate refers to the construction waste obtained after crushing, sieving, and removing foreign matter, and the particle size is 2-10mm, and the reinforcing agent is silica fume powder and redispersible Latex powder is the mixture of 1:3 by mass ratio, and described curing agent is made of 12% calcium sulfate, 12% sodium chloride, 12% calcium chloride, 12% ammonium bicarbonate, 12% potassium carbonate and 40% water by mass percentage Prepared by mixing.

[0028] The preparation method of above-mentioned construction waste recycled concrete comprises the following steps:

[0029] (1) Take the following ...

Embodiment 3

[0032] The construction waste recycled concrete of this embodiment is made of the following raw materials: 70 kg of construction waste recycled aggregate, 10 kg of reinforcing agent, 15 kg of water reducing agent, 10 kg of curing agent, 15 kg of mineral powder, 30 kg of Portland cement cement, and 150 kg of water and polyamide 10kg, wherein, the construction waste regenerated aggregate refers to the construction waste with a particle size of 2-10mm obtained after crushing, sieving, and removing foreign matter, and the reinforcing agent is silica fume powder and redispersible Latex powder is the mixture of 1:3 by mass ratio, and described curing agent is made of 12% calcium sulfate, 12% sodium chloride, 12% calcium chloride, 12% ammonium bicarbonate, 12% potassium carbonate and 40% water by mass percentage Prepared by mixing.

[0033] The preparation method of above-mentioned construction waste recycled concrete comprises the following steps:

[0034] (1) Take the following ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com