Main engine tipping bucket oblique angle type lifting door stable type garbage compression equipment

A garbage compression and stable technology, applied in the directions of garbage conveying, garbage collection, loading/unloading, etc., it can solve the problems of asynchrony between the two power mechanisms, easy winding, and easy wear of the wire rope, and achieve reliable turning action, high fault tolerance, Guaranteed balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

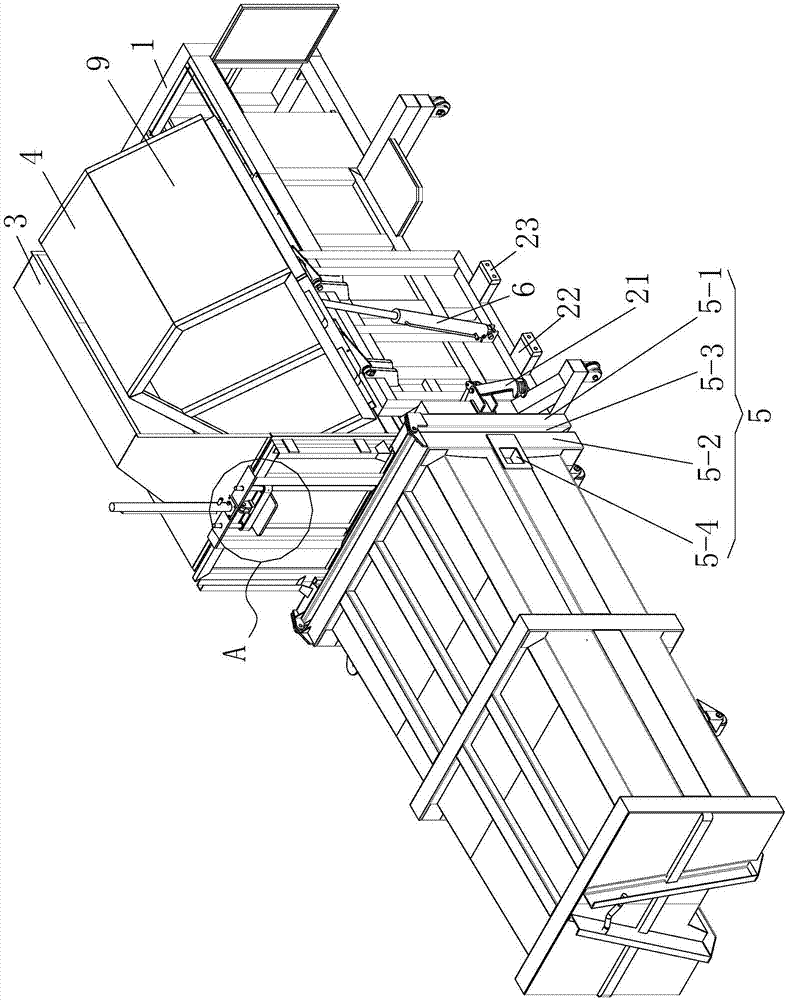

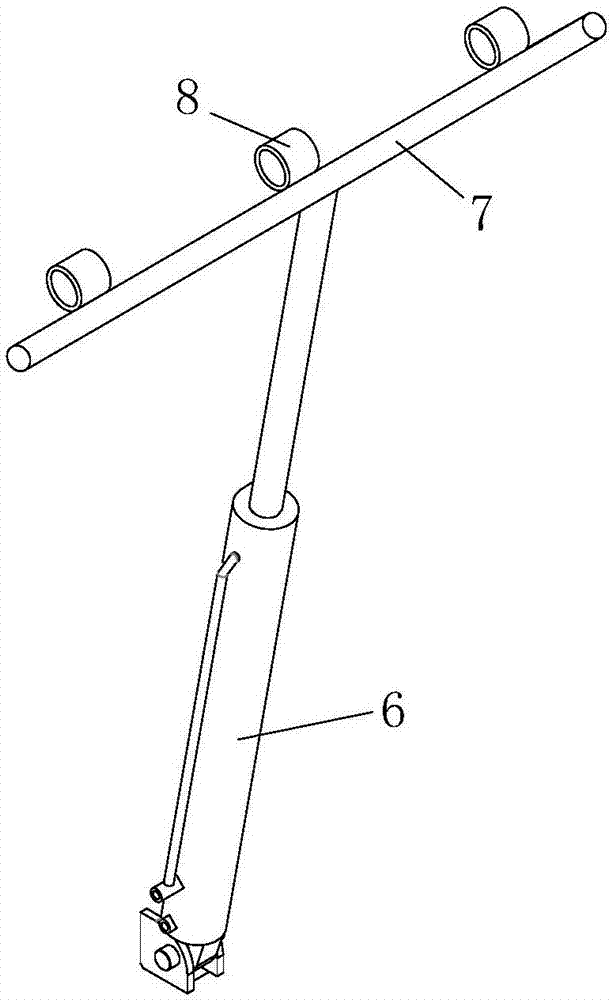

[0022] See Figure 1 to Figure 4 , the present invention has a frame 1, a lifting cylinder 2, a hopper cover 3, a tipping bucket 4 and a container 5; the frame 1 and the container 5 are provided with a lifting cylinder 2; the hopper cover 3 is fixedly installed on the top of the frame 1; the tipping bucket 4 corresponds to the hopper The position of the cover 3 is set, and both sides of the tipping bucket 4 are hinged on the frame 1; the connection between the container 5 and the frame 1 is detachable; the tipping bucket 4 is turned over by a power mechanism fixed at one end on the frame 1; It includes a turning cylinder 6 symmetrically hinged on the frame 1; a cross bar 7 is connected to the piston rod of the turning oil cylinder 6; Above; the outside of the dump bucket 4 is an inclined plane 9; the angle between the inclined plane 9 and the extension line at the bottom of the dump bucket 4 is 30° to 75°; the inner side of the lifting cylinder 2 at the output port of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com