Umbrella-parallel-structure three-dimensional ultrasonic elliptic vibration cutting device and track generation method

A technology of elliptical vibration and cutting device, which is applied in the direction of fluid using vibration, can solve the problems of small working stroke, low natural frequency, and low operating frequency, and achieve high vibration frequency, compact micro-nano texture, and simple and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0051] In order to achieve the above object, the solution of the present invention is:

[0052] 1. An umbrella-shaped and elliptical vibration auxiliary cutting device, characterized in that:

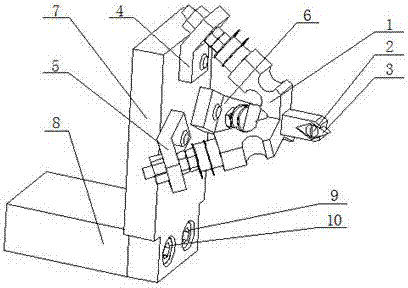

[0053] The device comprises an umbrella-shaped parallel flexible hinge structure 1, a cutter 3, a first folded plate 4, a second folded plate 5, a third folded plate 6, a support plate 7, a spacer 8, such as figure 1 shown;

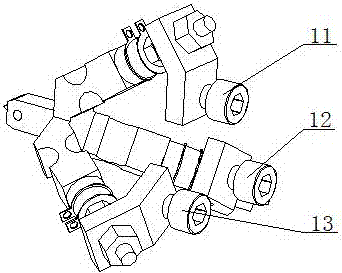

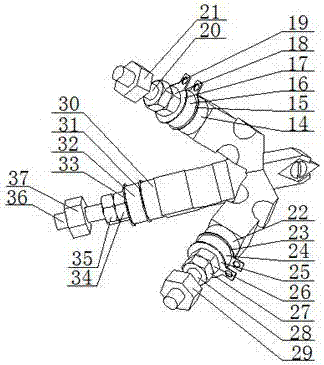

[0054] The above-mentioned umbrella-shaped parallel flexible hinge structure 1 includes a first branch chain 101, a second branch chain 102, a third branch chain 103 and a tool mounting platform 104, such as Figure 4 shown.

[0055] the above Figure 4 The three branch chain structures shown are exactly the same, and they are all composed of a straight circular flexible hinge 1021 structure and a displacement input rod 1022;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com