Novel powder-laying system for selective laser melting and forming device

A technology of laser selective melting and forming equipment, applied in the field of additive manufacturing, can solve the problems of difficult forming and processing of various materials, inconvenient powder recycling, and difficult sealing, and achieve the effect of isolating air, reducing the amount of powder recycling, and facilitating replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

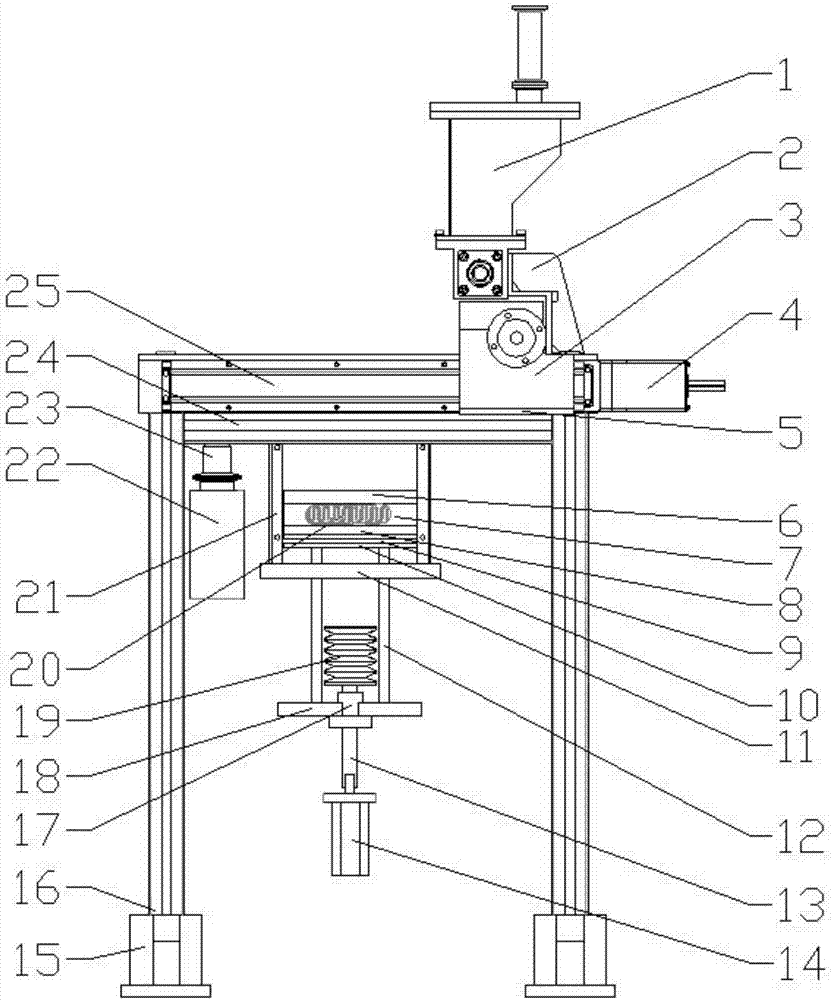

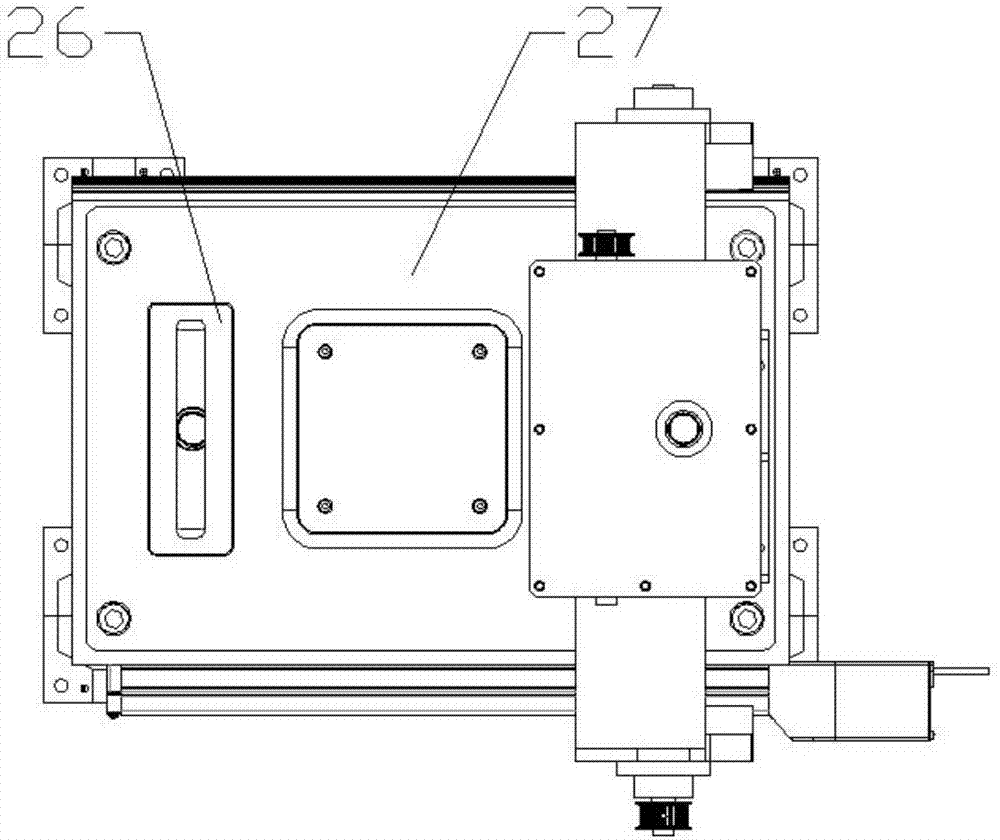

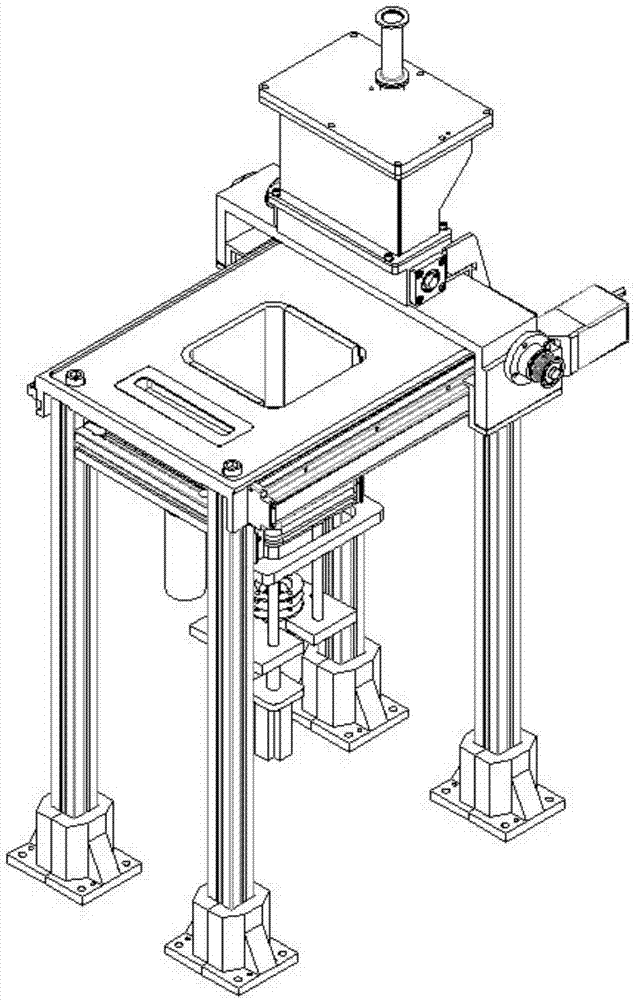

[0015] A new type of powder spreading system for laser selective melting and forming equipment, including powder feeding device 1, bracket 2, powder spreading device 3, linear motor 4, slider 5, base plate 6, heating plate 7, heat insulation plate 8, sealing Rubber 9, transition plate 10, forming cylinder bottom plate 11, connecting rod 12, lead screw 13, Z-direction servo motor 14, base 15, support frame 16, lead screw nut 17, lifting plate 18, lead screw cover 19, resistance wire Heating device 20 , forming cylinder 21 , recovery bin 22 , recovery pipe 23 , connecting frame 24 , guide rail 25 , recovery baffle plate 26 , and workbench 27 .

[0016] combine figure 1 and figure 2 , the four support frames 16 are installed on the four bases 15, the base 15 is fixedly installed on the ground, and then the four support frames 16 are connected and fixed by the connecting frame 24, and the workbench 27 is horizontally installed and fixed on the connected frame. Guide rail 25 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com