Stable amino acid soap and its preparation method

An amino acid and acyl amino acid technology, applied in the field of daily necessities, can solve the problems of high skin irritation, adverse effects, damage to the mildness of amino acid soap, etc., and achieve the effects of good skin feel, resistance to discoloration, and fragrance retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

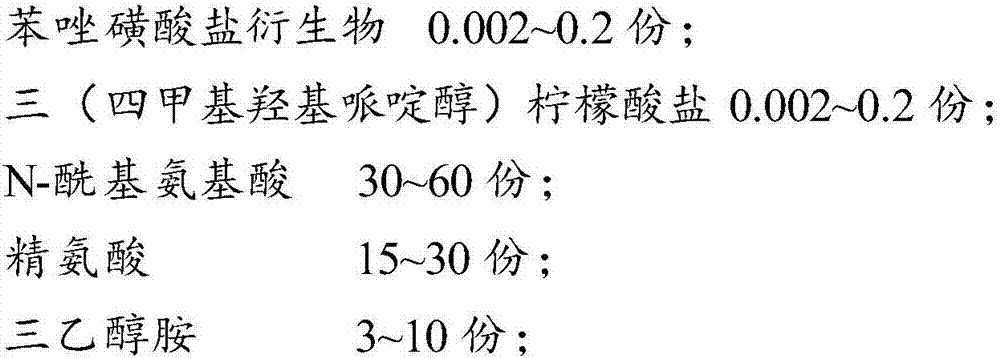

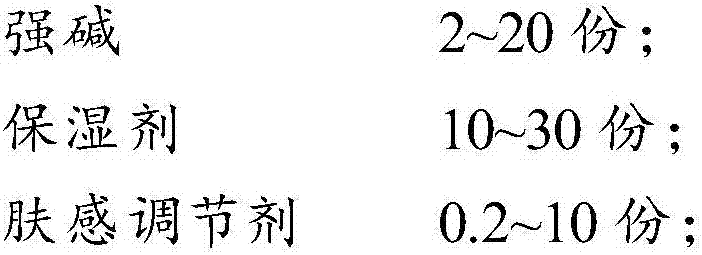

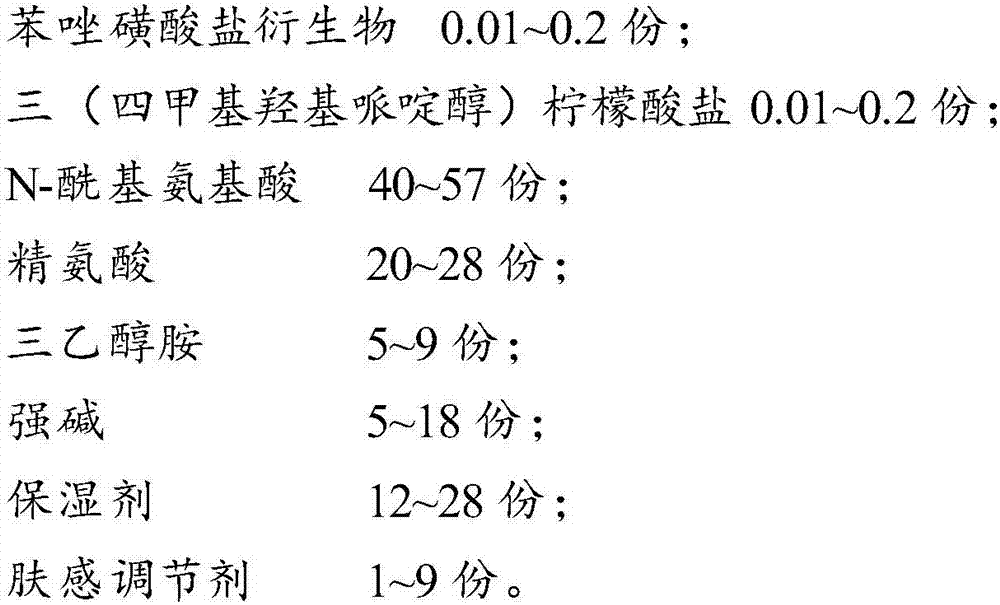

Method used

Image

Examples

preparation example Construction

[0067] The present invention provides a kind of preparation method of amino acid soap as described in above-mentioned technical scheme, comprises the steps:

[0068] A) mixing the N-acyl amino acid and the moisturizing agent, heating and stirring to obtain the first mixed liquid;

[0069] Mixing and heating triethanolamine, arginine, and a strong base to obtain a second mixed solution;

[0070] B) Mix the first mixed solution with the second mixed solution, mix with the skin feeling regulator after mixing, cool down after mixing, and then mix with benzosulfonate derivatives, tris(tetramethylhydroxypiperidinol) citric acid Salt is mixed, obtains the 3rd mixed liquor;

[0071] C) Defoaming the third mixed solution, filling it into a mold to obtain amino acid soap.

[0072] In the present invention, the N-acyl amino acid and the moisturizing agent are firstly mixed, heated and stirred to obtain the first mixed solution.

[0073] The present invention has clearly described the ...

Embodiment 1~2

[0116] Embodiment 1~2, comparative example 1~4

[0117] (1) Formulation:

[0118]

[0119] Polyglycerol-10

1%

1%

1%

1%

1%

1%

essence

0.5%

0.5%

0.5%

0.5%

0.5%

0.5%

water

margin

margin

margin

margin

margin

margin

[0120] (2) Preparation method

[0121] 1) Mix lauroyl glutamic acid, glycerin and 50% water, stir at a constant speed and heat to 80°C.

[0122] 2) Weigh triethanolamine (Dow), arginine, sodium hydroxide, and the rest of water, and heat to 80°C

[0123] Finally, slowly add the mixed solution obtained in step 1), stir well and then add polyglycerol-10.

[0124] 3) Cool down to 55°C, quickly add flavor, benzosulfonate derivatives and tris(tetramethyl)

[0125] Hydroxypiperidinol) citrate).

[0126] 4) Put it into the mold and fill it, and quickly cool down and solidify.

[0127] (3) Quality evaluation

[0128] Adopt method of the present invention to measure its performance,...

Embodiment 3~6

[0147] Embodiment 3~6, comparative example 5~8

[0148]

[0149] (1) Formula

[0150] (2) Preparation method

[0151] 1) Mix stearoyl glutamic acid, palmitoyl glutamic acid, cocoamidopropionic acid, glycerin with 50% water, stir at a constant speed and heat to 90°C.

[0152] 2) Mix triethanolamine (Dow), arginine, sodium hydroxide, and the remaining water, heat to 90°C, slowly add to the mixture obtained in step 1), stir well, and then add polyglycerol-10.

[0153] 3) Cool down to 60°C, and quickly add folic acid, niacinamide, creatine, essence, benzosulfonate derivatives and tris(tetramethylhydroxypiperidinol) citrate).

[0154] 4) Put it into the mold and fill it, and quickly cool down and solidify.

[0155] (3) Quality evaluation

[0156] Adopt method of the present invention to measure its performance, wherein, measurement result is as follows:

[0157] Table 7 shows the peroxide value measurement results of Examples 3-6 and Comparative Examples 5-8 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com