Detoxification method of vomitoxin in process of corn deep processing

A technology for deep processing of vomitoxin, which is applied in the field of corn deep processing, can solve the problems of unqualified, polluted, ineffective detoxification of corn by-product vomitoxin, etc., and achieve the effect of bright yellow color, improved economic benefits, and remarkable detoxification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

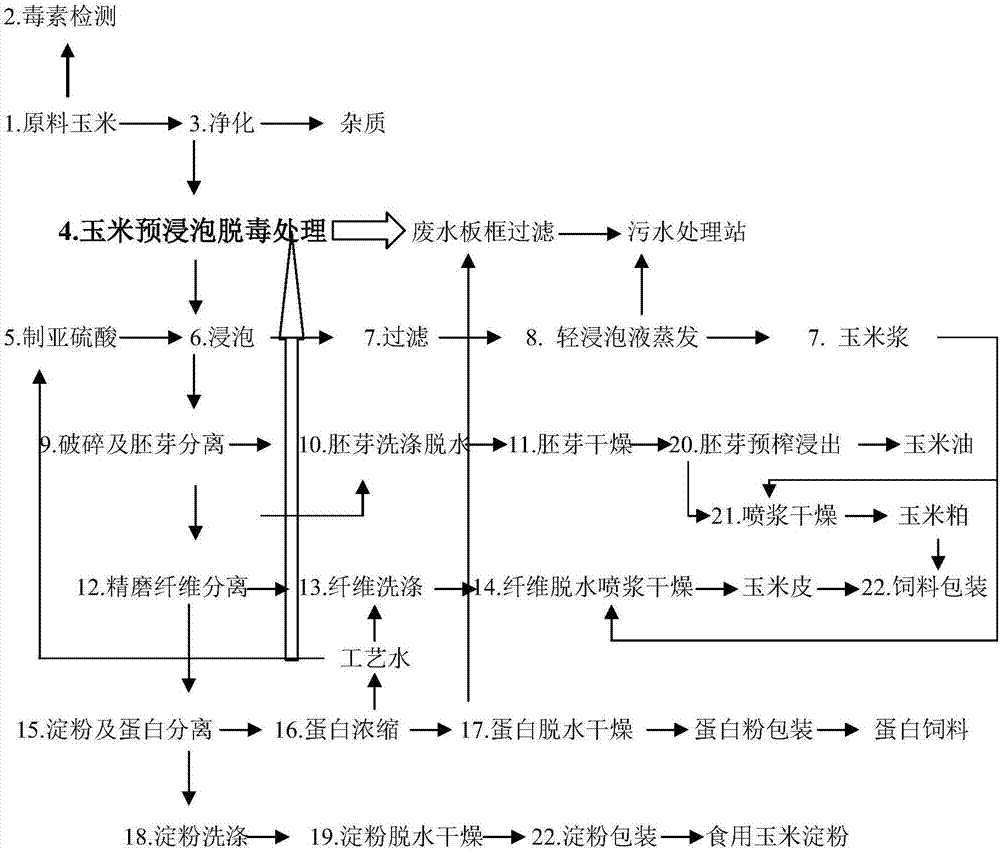

Method used

Image

Examples

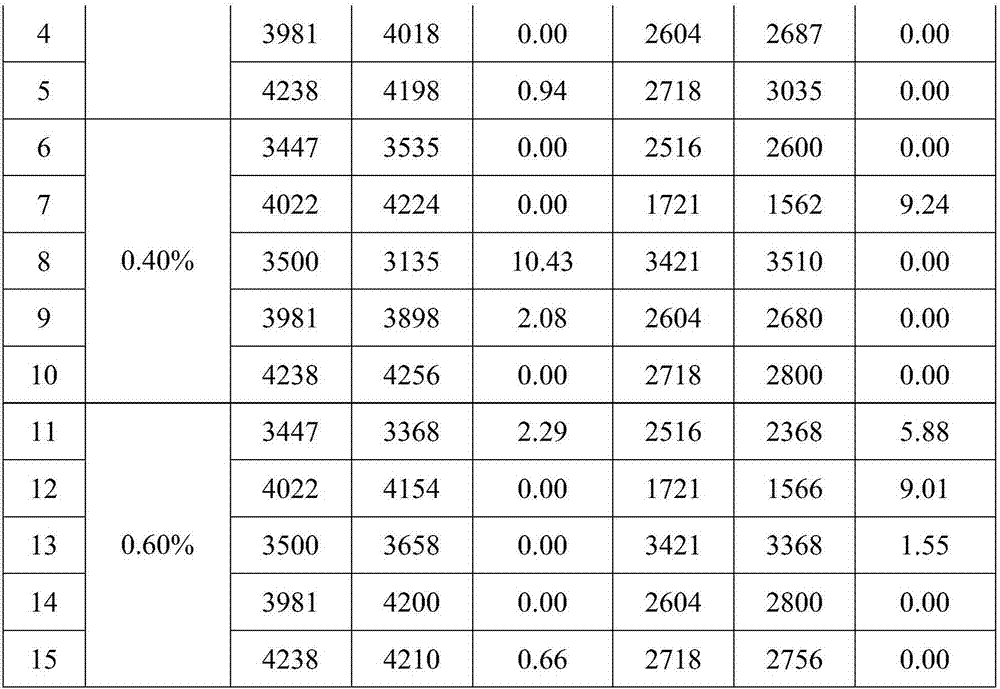

Embodiment 1

[0028] Include the following steps:

[0029]After the raw corn is tested and purified, it enters each corn soaking tank, and the circulating process water is poured into the corn soaking tank for pre-soaking. The process water is overflowed after being centrifuged in the last gluten concentration centrifuge in the corn protein concentration process. Process water, the temperature is 48°C, the mass ratio of process water to raw corn is 0.9:1, keep the process water level in the tank below the corn, and regularly check whether the corn in the tank is completely submerged;

[0030] Soaking time: Soak wet grain for 1 hour, soak dry grain for 2 hours, use circulating heating to keep the temperature of the soaking tank at 48°C during soaking; soak two cans of corn in the process water circulation: when one can of corn is pre-soaked, the process water in the tank Use a circulation pump to drive into the next tank. After the next tank of corn is pre-soaked with process water, the proc...

Embodiment 2

[0033] Include the following steps:

[0034] After the raw corn is tested and purified, it enters each corn soaking tank, and the circulating process water is poured into the corn soaking tank for pre-soaking. The process water is overflowed after being centrifuged in the last gluten concentration centrifuge in the corn protein concentration process. Process water, the temperature is 50°C, the mass ratio of process water to raw corn is 0.9:1, keep the process water level in the tank below the corn, and regularly check whether the corn in the tank is completely submerged;

[0035] Soaking time: Soak wet grain for 1 hour and dry grain for 2 hours. During the soaking period, use circulating heating to keep the temperature of the soaking tank at 50°C; soak two cans of corn in the process water circulation: when one can of corn is pre-soaked, the process water in the tank Use a circulation pump to drive into the next tank. After the next tank of corn is pre-soaked with process wate...

Embodiment 3

[0038] Include the following steps:

[0039] After the raw corn is tested and purified, it enters each corn soaking tank, and the circulating process water is poured into the corn soaking tank for pre-soaking. The process water is overflowed after being centrifuged in the last gluten concentration centrifuge in the corn protein concentration process. Process water, the temperature is 52°C, the mass ratio of process water to raw corn is 0.9:1, keep the process water level in the tank below the corn, and regularly check whether the corn in the tank is completely submerged;

[0040] Soaking time: Soak wet grain for 1 hour and dry grain for 2 hours. During the soaking period, use circulating heating to keep the temperature of the soaking tank at 52°C; soak two cans of corn in the process water cycle: when one can of corn is pre-soaked, the process water in the tank Use a circulation pump to drive into the next tank. After the next tank of corn is pre-soaked with process water, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com