Extraction process for bovine serum albumin by graduated heat shock method

A technology for bovine serum albumin and extraction process, which is applied in the field of albumin preparation, can solve the problems of difficulty in guaranteeing albumin purity, difficult mass production, complicated production process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

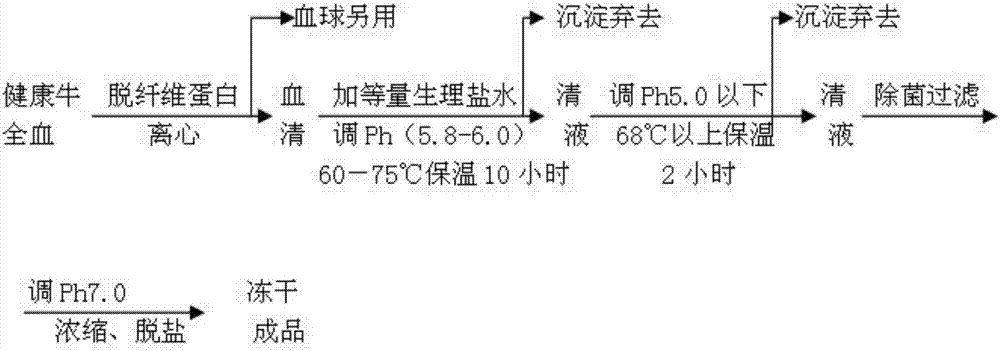

Image

Examples

Embodiment 1

[0020] A kind of bovine serum albumin graded heat shock method extraction process, comprises the steps:

[0021] 1. Separation of serum: Fresh whole blood from healthy cattle, defibrinated, collected by continuous centrifugation, and red blood cells are used separately;

[0022] 2. Extraction: Add serum and the same amount of normal saline into the reaction tank, stir at 20 rpm, add 0.32% sodium caprylate while stirring to fully combine with albumin; add 0.1M dilute hydrochloric acid, adjust the pH to 5.8, add Heat at 60°C for 10 hours, filter to remove the precipitate, adjust the pH to 4.5 in the clear night, heat at 60°C, keep warm for 2 hours, filter to remove the precipitate, collect the clear liquid, filter to remove the precipitate, and collect the clear liquid;

[0023] 3. Concentration, desalination and in-situ sterilization and filtration: the clear liquid is adjusted to PH to 6.8 and then sterilized by circulation, concentrated and eluted by ultrafiltration with a 10...

Embodiment 2

[0026] A kind of bovine serum albumin graded heat shock method extraction process, comprises the steps:

[0027] 1. Separation of serum: Fresh whole blood from healthy cattle, defibrinated, collected by continuous centrifugation, and red blood cells are used separately;

[0028] 2. Extraction: Add serum and the same amount of normal saline into the reaction tank, stir at 40rpm, add 0.38% sodium caprylate while stirring to fully combine with albumin; add 0.1M dilute hydrochloric acid, adjust the pH to 6.0, add Incubate at 75°C for 10 hours, filter to remove the precipitate, adjust the pH to 5.0 at night, heat at 75°C, keep warm for 3 hours, filter to remove the precipitate, and collect the supernatant;

[0029] 3. Concentration, desalination and in-situ sterilization and filtration: the clear liquid is adjusted to PH to 7.2 and then sterilized by circulation, concentrated and eluted by ultrafiltration with a 10,000 molecular weight ultrafiltration membrane, and the final concen...

Embodiment 3

[0032] A kind of bovine serum albumin graded heat shock method extraction process, comprises the steps:

[0033] 1. Separation of serum: Fresh whole blood from healthy cattle, defibrinated, collected by continuous centrifugation, and red blood cells are used separately;

[0034] 2. Extraction: Add serum and the same amount of normal saline to the reaction tank, stir at 30rpm, add 0.35% sodium caprylate while stirring to fully combine with albumin; add 0.1M dilute hydrochloric acid, adjust the pH to 6.0, add Incubate at 65°C for 10 hours, filter to remove the precipitate, adjust the pH to 5.0 in the clear night, and heat to 75°C when the pH is adjusted to 5.0, filter to remove the precipitate after 3 hours of heat preservation, and collect the supernatant;

[0035] 3. Concentration, desalination and in-situ sterilization and filtration: the clear liquid is adjusted to PH to 7.0 and then sterilized by circulation, concentrated by ultrafiltration with a 10,000 molecular weight ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com