Method and device for purifying flue gas and controlling smoke plume

A flue gas purification and control device technology, which is applied in the direction of chemical instruments and methods, combined devices, separation methods, etc., can solve the problem of unclear mechanism of synergistic removal, achieve improvement of white plume problem, save water resources, and achieve high efficiency The effect of synergistic removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

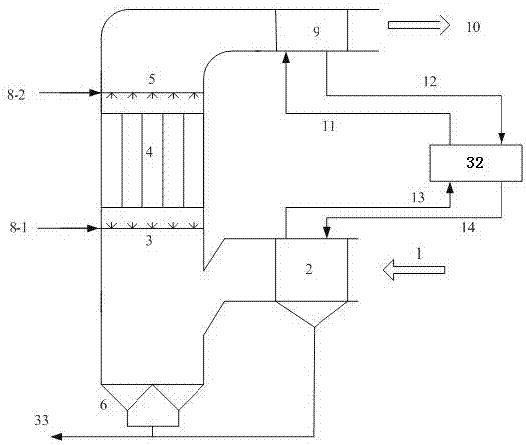

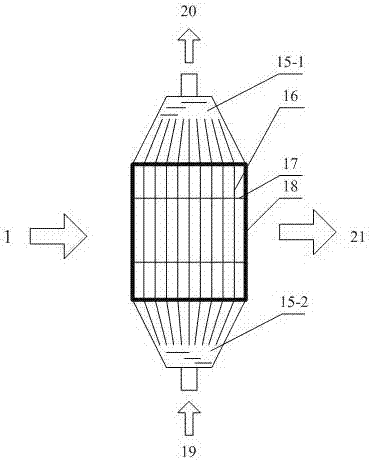

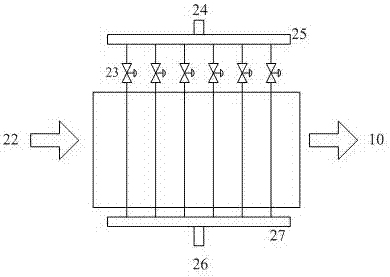

[0037] Such as Figure 1-Figure 4 As shown, the flue gas purification and plume control device of the present invention includes a heterogeneous nucleation agglomeration reaction system, a flue gas deep purification system, a flue gas heating reaction system, and a heat pump circulation system arranged in sequence along the flue gas flow direction. Among them, the heterogeneous nucleation and agglomeration reaction system is set at the entrance of the device, the flue gas deep purification system is set in the vertical section of the device, and the gas heating reaction system is set in the horizontal section of the device.

[0038] The heat pump circulation system connects the heterogeneous nucleation and agglomeration reaction system and the flue gas heating reaction system through pipelines. The flue gas is purified by the heterogeneous nucleation and agglomeration reaction system, and then enters the flue gas deep purification system to further remove fine particles and und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com