A preparing method of a cosmetic medical microneedle paster

A production method and technology of microneedle sticking, applied in the direction of microneedles, needles, medical devices, etc., can solve the problems of increasing process complexity, production cost, and increasing process difficulty, so as to improve mass production efficiency and save process time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

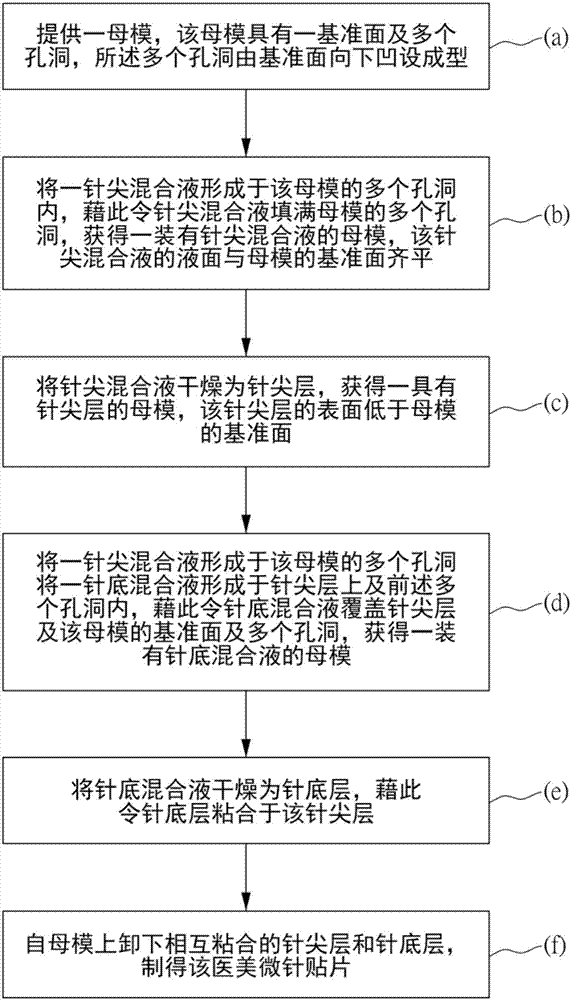

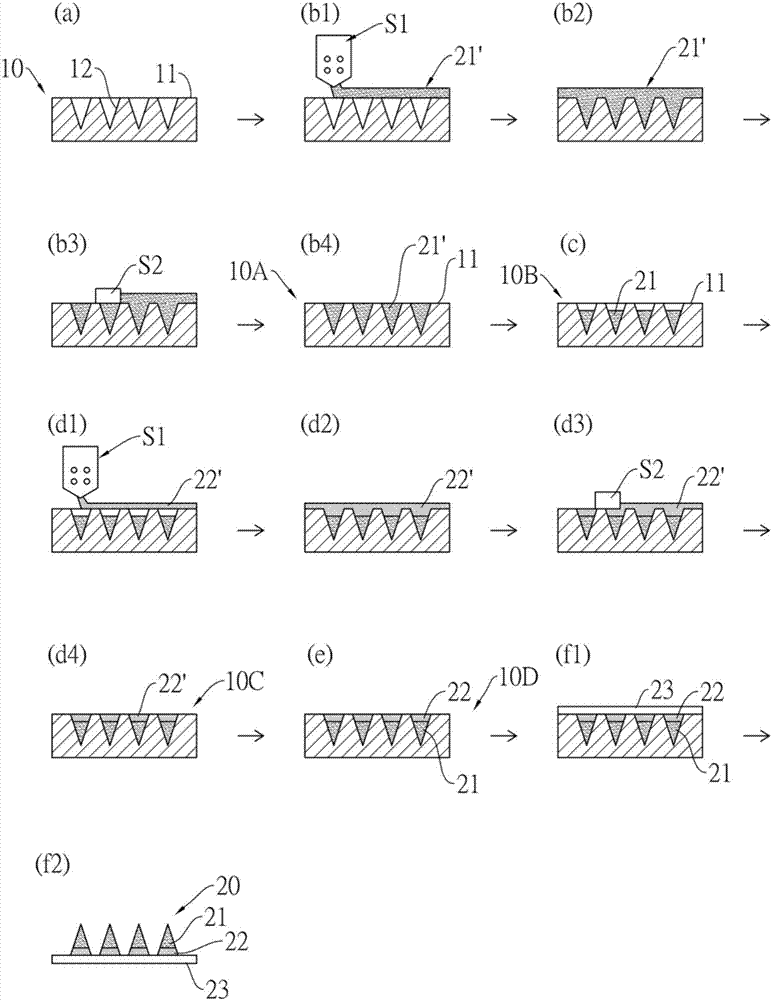

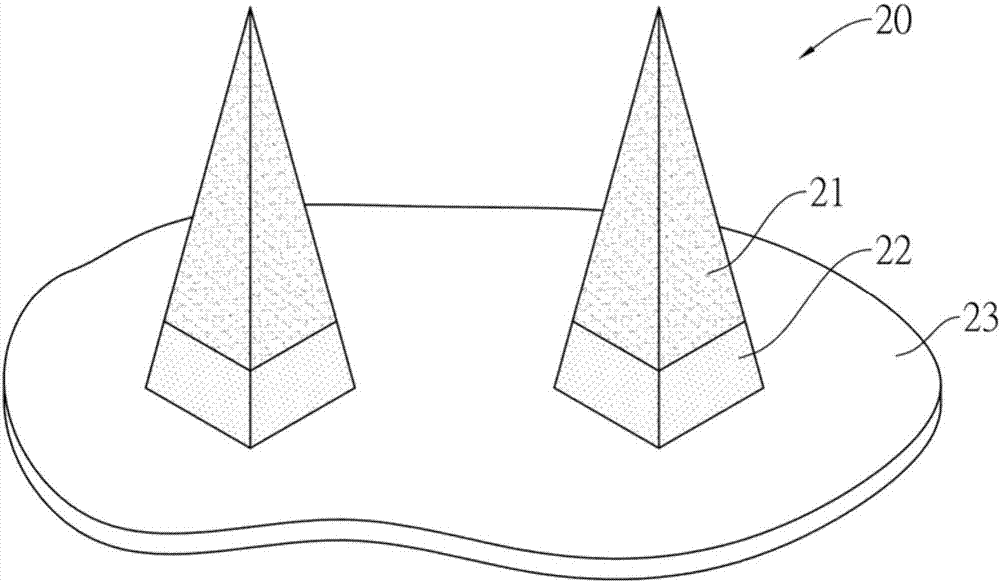

[0068] Please refer to figure 1 and figure 2 As shown, the medical aesthetic microneedle patch of this embodiment is prepared by the following method.

[0069] First, if figure 1 and figure 2 In the step (a) shown, a master mold 10 is prepared, the master mold 10 has a reference plane 11 and a plurality of holes 12, and the plurality of holes 12 are recessed downward from the datum plane 11, and the plurality of holes A plurality of holes 12 are recessed on the master mold 10 in a matrix arrangement. In this embodiment, the material of the master mold 10 is PDMS, and the hole density on the master mold 10 is 289 holes / cm 2 , the hole array range is 1.5cm × 1.5cm, the shape of each hole 12 is a square cone, its depth (that is, the vertical distance between the end of the hole 12 and the reference plane 11) is 750 μm, and the maximum width (that is, the hole 12 and the reference plane 11 The maximum inner diameter of the flush horizontal plane) is 300 μm.

[0070] Then, ...

Embodiment 2

[0078] In this example, the medical beauty microneedle patch is generally prepared by the method described in Example 1 above. The main difference is that in this example, the needle-tip mixed solution and the needle-bottom mixed solution are coated by the scraper coating method. , fix the needle base mixture in multiple holes in a centrifugal manner, and omit the step of scraping the needle base mixture.

[0079] Specifically, after the step (a), the step (b1) is performed using a doctor blade coating method, and the needle-tip mixture is coated on the master mold with a coating gap of 1000 μm and a coating speed of 3 m / min; Then through steps (b2) to (b4) and (c) as described in Example 1 in sequence, a master mold with a pinpoint layer was obtained. The needle tip mixture is an aqueous solution of 20wt% blue copper peptide and methyl vinyl ether-maleic anhydride copolymer, and the needle tip mixture is heated at 25°C for 1S -1 The measured viscosity is 40cP, and its surfac...

Embodiment 3

[0083] In this example, the medical beauty microneedle patch is generally prepared by the method described in Example 1 above. The main difference is that in this example, the needle-tip mixed solution and the needle-bottom mixed solution are coated by the scraper coating method. In addition, change the structure of the master mold and omit the step of scraping off the mixed liquid at the bottom of the needle. In addition, the composition of the needle-tip mixture used in this embodiment is also different from the composition of the needle-tip mixture in Example 1. For the detailed production process of this embodiment, please refer to Figure 4 As shown, the following will match figure 1 and Figure 4 The production method of this example will be described.

[0084] First, if figure 1 and Figure 4 In step (a) shown, a master mold 10 is prepared, and the master mold 10 has a reference plane 11 and a plurality of holes 12 . In this embodiment, the material of the master ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com