Conveying structure and mounting method thereof

An installation method and a technology for connecting joints, applied in the direction of circuits, passing components, electrical components, etc., can solve the problems of low strength of cooling pipe joints and low efficiency of finished products, so as to reduce manual workload, increase yield, and strengthen connections intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

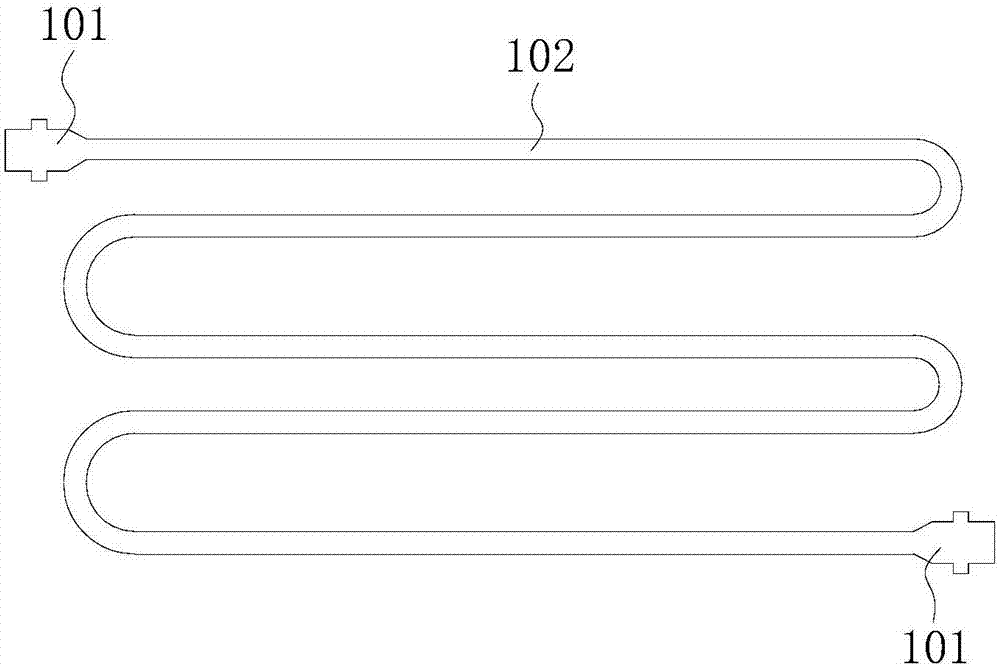

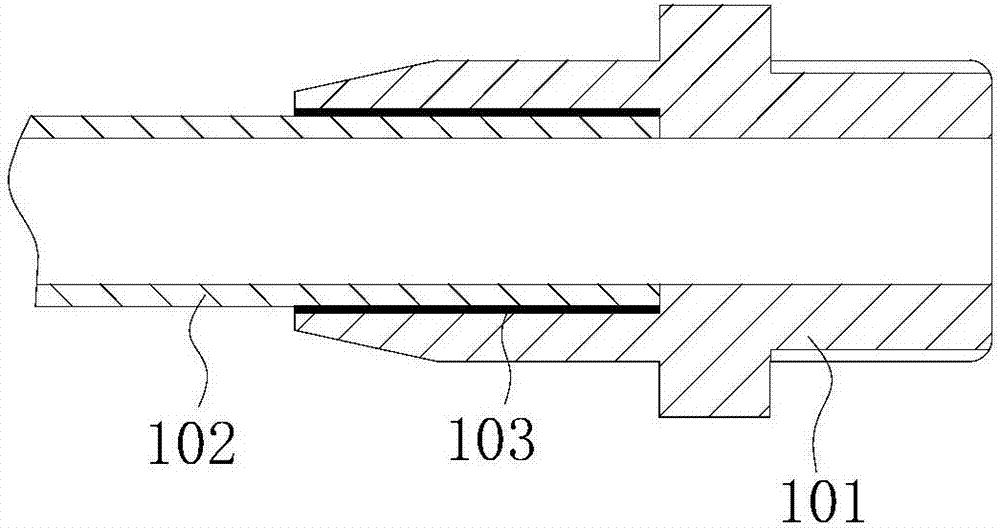

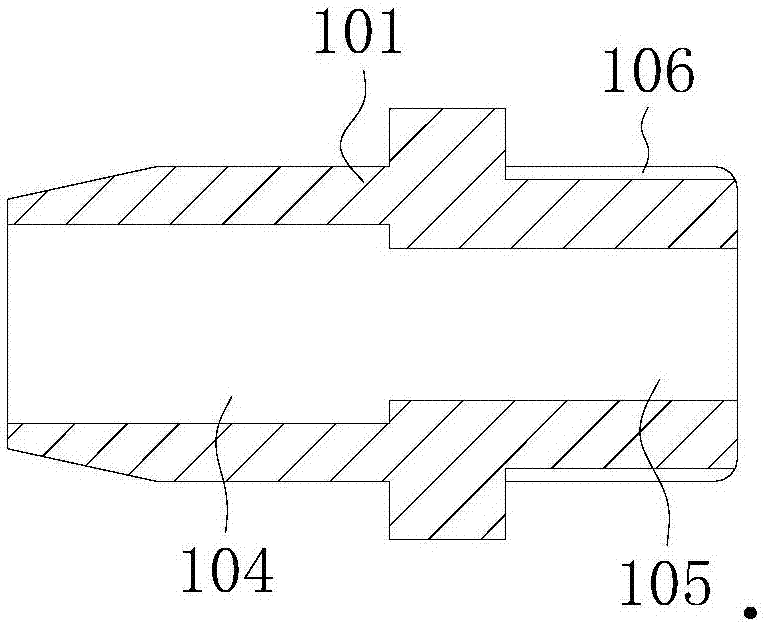

[0051] refer to Figure 1 to Figure 4 , the present embodiment provides a delivery structure, including a connecting joint 101, the connecting joint 101 is provided with a first through hole 104 and a second through hole 105, the first through hole 104 communicates with the second through hole 105, the first through hole 104 is a waist-shaped hole, the second through hole 105 is a circular hole, and the length of the first through hole 104 is greater than the diameter of the second through hole 105 .

[0052] The cooling water pipe 102 is arranged under the power battery, and due to the narrow space and compact structure, its shape must be set to be flat. The first through hole 104 of the conveying structure provided by this embodiment is flat, which can facilitate the installation of the cooling water pipe 102. This connection method can greatly enhance the connection strength between the cooling water pipe 102 and the conveying structure. At the same time, because the first ...

Embodiment 2

[0060] refer to Figure 5 , the present embodiment provides an installation method, first fill the soldering material 103 in the first through hole 104 of the connecting joint 101 of the delivery structure, then insert the cooling water pipe 102 into the first through hole 104, and then connect the connecting joint Heat treatment is carried out at the first through hole 104 of 101, and finally cooled until the solder is solidified.

[0061] The installation method provided in this embodiment can ensure the connection strength between the connection joint 101 and the cooling water pipe 102 after the cooling water pipe 102 is connected with the connection joint 101, because the connection length and the connection area between the connection joint 101 and the cooling water pipe 102 Larger, so there will be no water leakage problem, and at the same time, the yield of installation can also be improved. Compared with existing technologies such as argon arc welding, the installation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com