Transmission combination, travel drive and method for controlling the transmission combination

A technology of transmission mechanism and driving device, which is applied in the direction of transmission device control, transmission device, fluid transmission device, etc., which can solve the problems of reduced comfort of clutch switching, and achieve the effect of process reliability, process and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

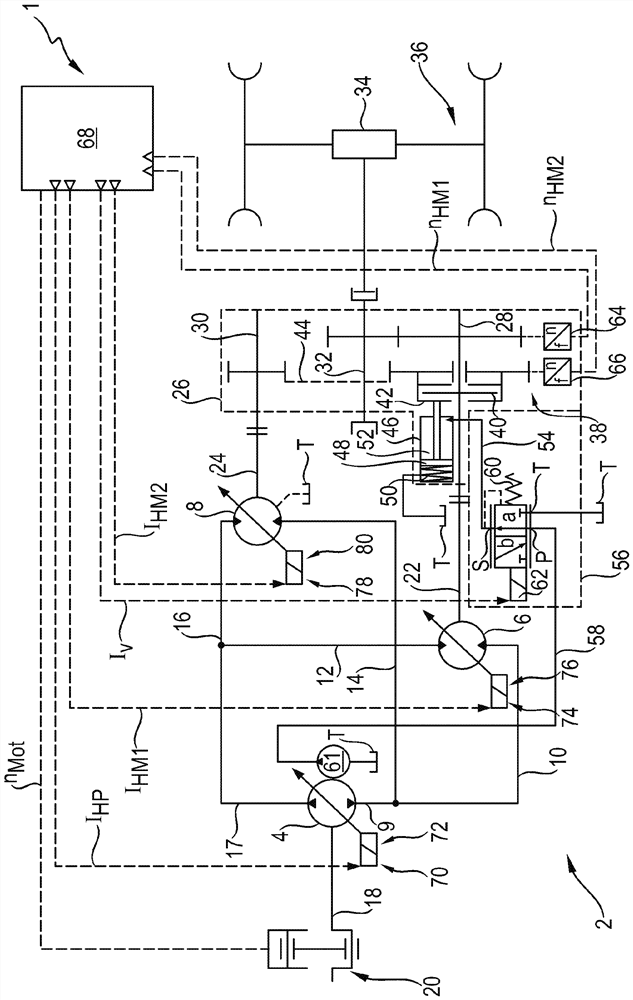

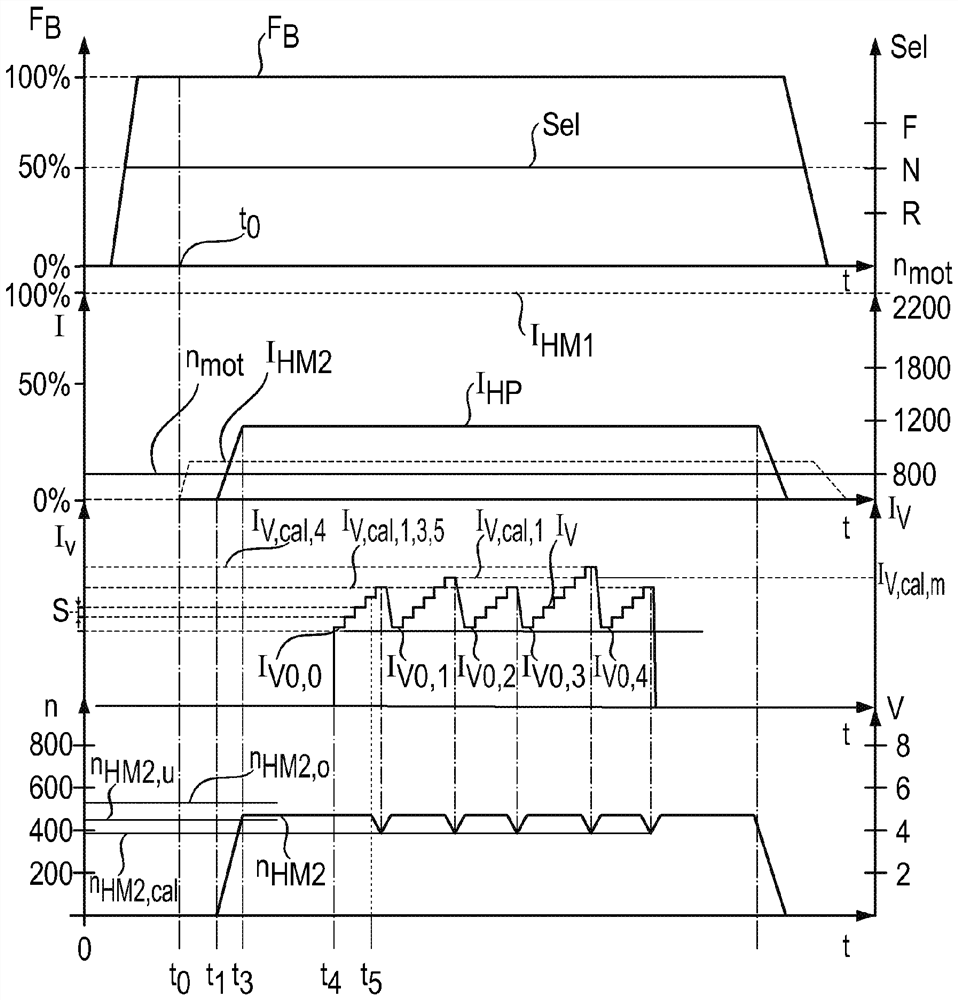

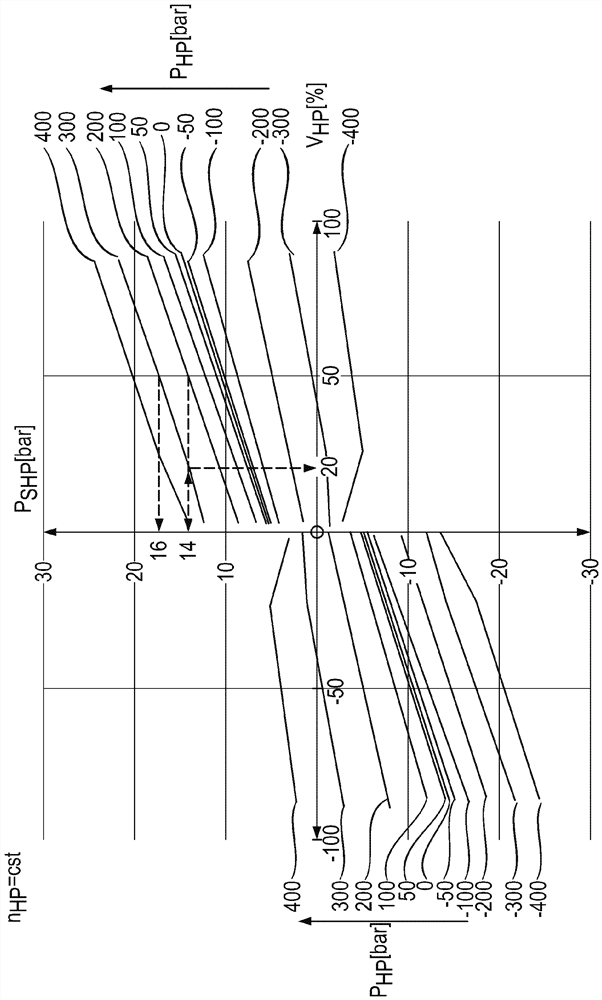

[0114] according to figure 1 , the traction drive 1 has a hydrostatic transmission 2 with a hydraulic machine 4 operating as a hydraulic pump in the traction operation of the traction drive 1 and two Hydraulic presses 6 and 8 working as hydraulic motors. The two hydraulic motors 6 , 8 are connected on the one hand to hydraulic pump 4 via working lines 10 and 12 and 14 and 16 and on the other hand are fluidly connected in parallel in a closed hydraulic circuit. The hydraulic machines 4 , 6 , 8 are adjustable with respect to their displacement volumes, wherein the hydraulic machines are each designed as axial piston machines with a swash plate design or an inclined shaft design.

[0115] The hydraulic pump 4 is connected via its drive shaft 18 to a power machine 20 designed as a diesel motor. The first hydraulic motor 6 of the two hydraulic motors 6 , 8 has a first drive shaft 22 and the second hydraulic motor 8 has a second drive shaft 24 . Behind the hydrostatic transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com