Method for manually building oil shale underground broken bodies

A technology of oil shale and broken bodies, which is applied in the field of artificially constructed oil shale underground broken bodies, which can solve the problems of small fracture porosity and permeability, inability to accurately control the extension direction, low permeability of natural oil shale layers, etc. , to achieve the effect of improving the seam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

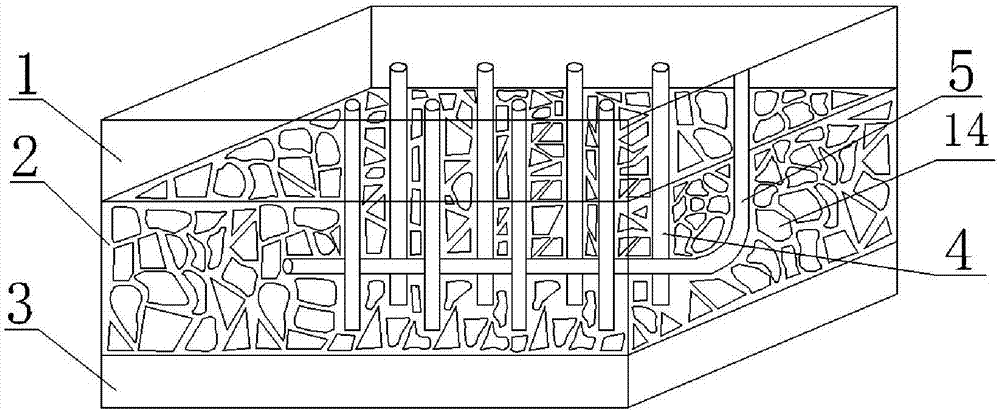

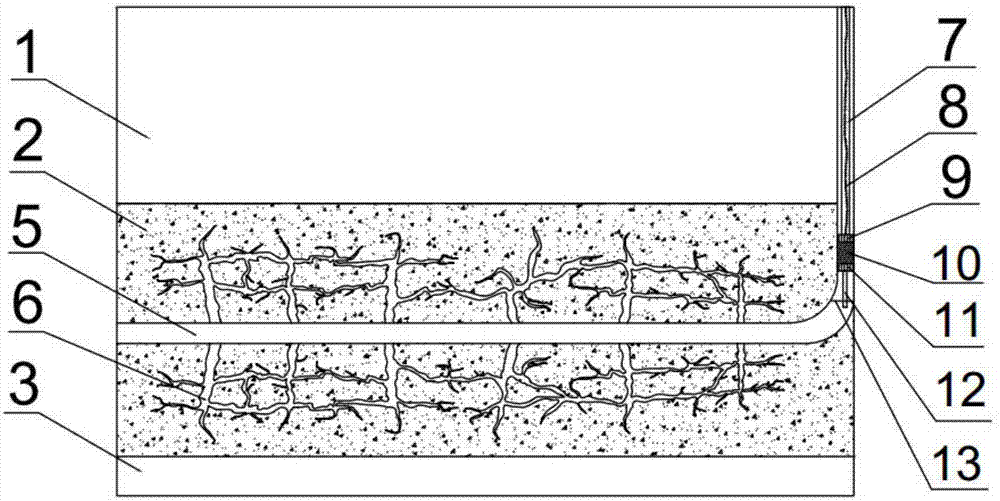

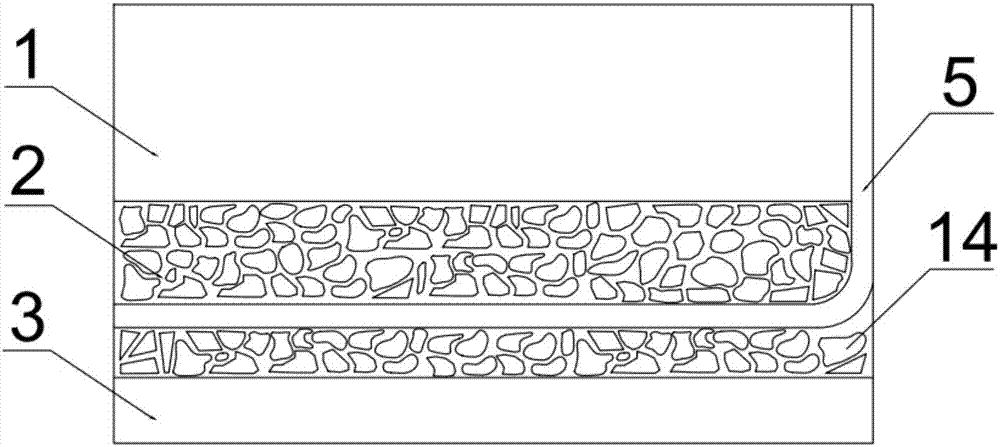

[0028] see figure 1 , figure 2 , image 3 , Figure 4 with 5 Shown, the present invention comprises the following steps:

[0029] 1) Determine the positions of the overlying rock mass 1 and the underlying rock mass 3 and the positions of the wells according to the situation of the oil shale in-situ mining project and the geological data of the oil shale mining area;

[0030] 2) After the construction plan is determined, start the first stage operation, construct a horizontal well 5, and the horizontal well 5 lies horizontally on the oil shale layer 2 to be exploited, and the construction work of the vertical well 4 is not carried out earlier;

[0031] 3) After the first-stage drilling operation is completed, the second-stage operation is carried out, and the horizontal well 5 is subjected to segmental fracturing. It is enough to provide the action site for the liquid explosive;

[0032] 4) After the second-stage fracturing operation is completed, the third-stage operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com