Comb-tooth type stereo garage

A three-dimensional garage and comb-tooth technology, which is applied to buildings, building types, buildings, etc. where cars are parked, can solve the problems of cumbersome access process and long access time of vehicles, and achieve improved land utilization, good stability, Shake reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

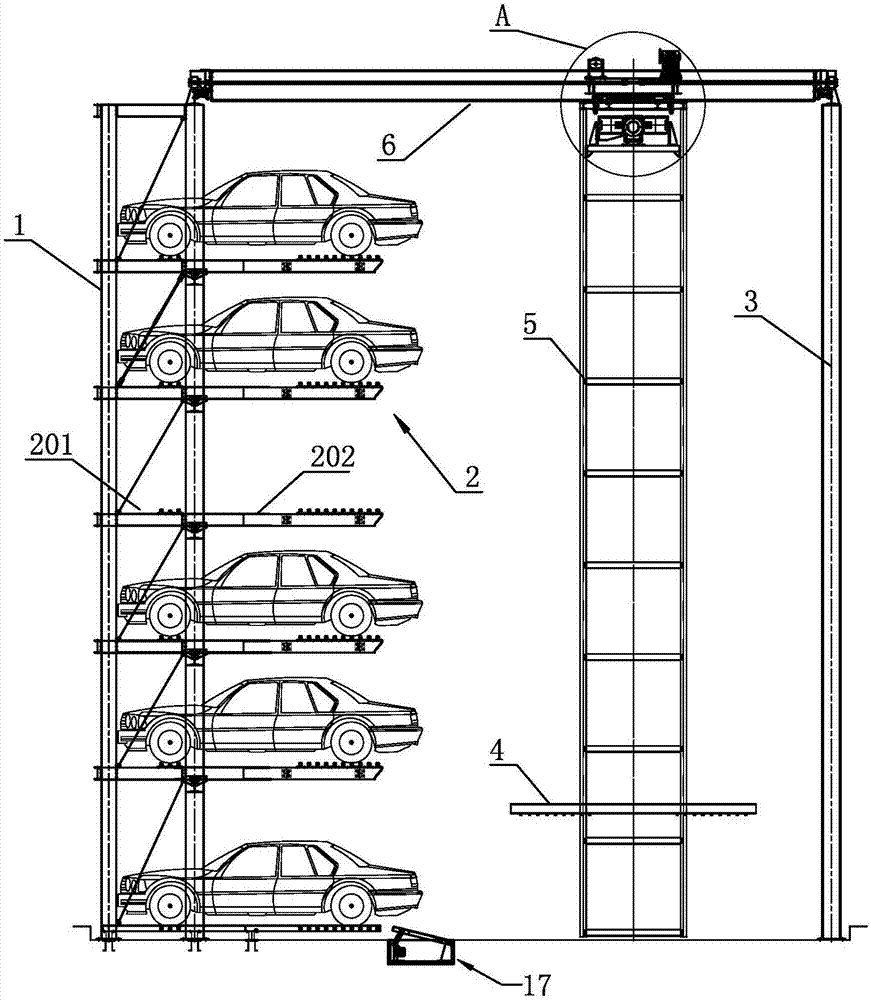

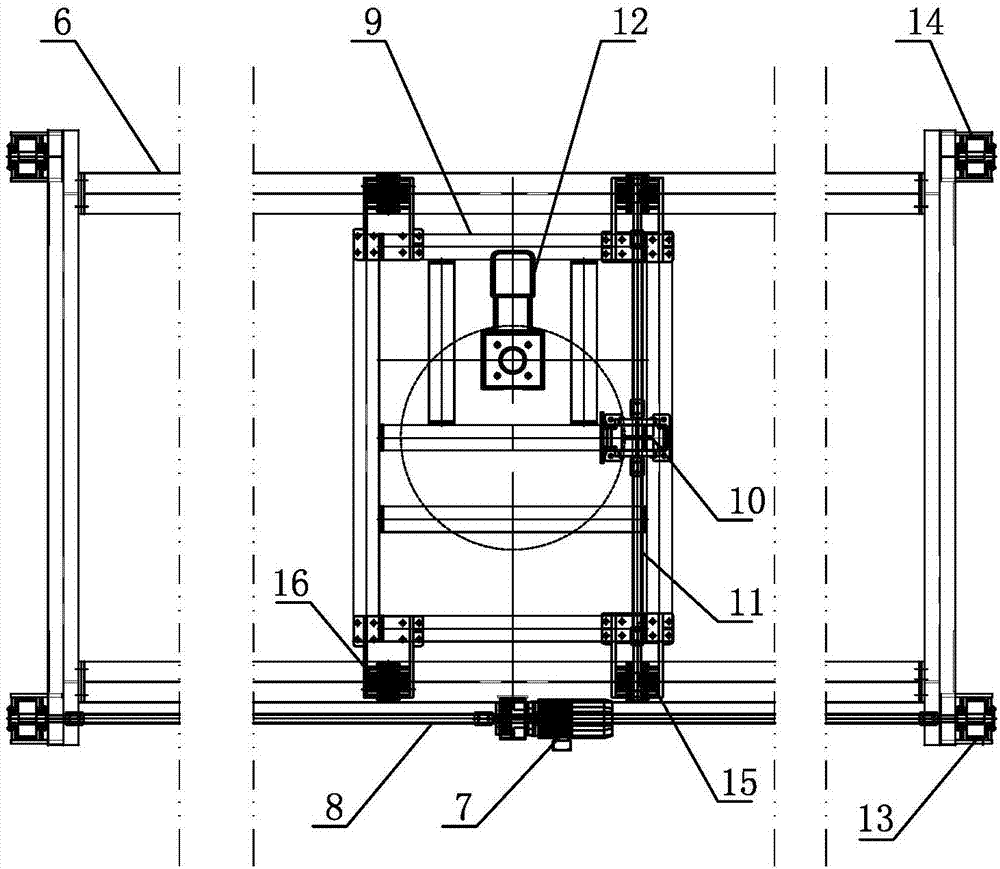

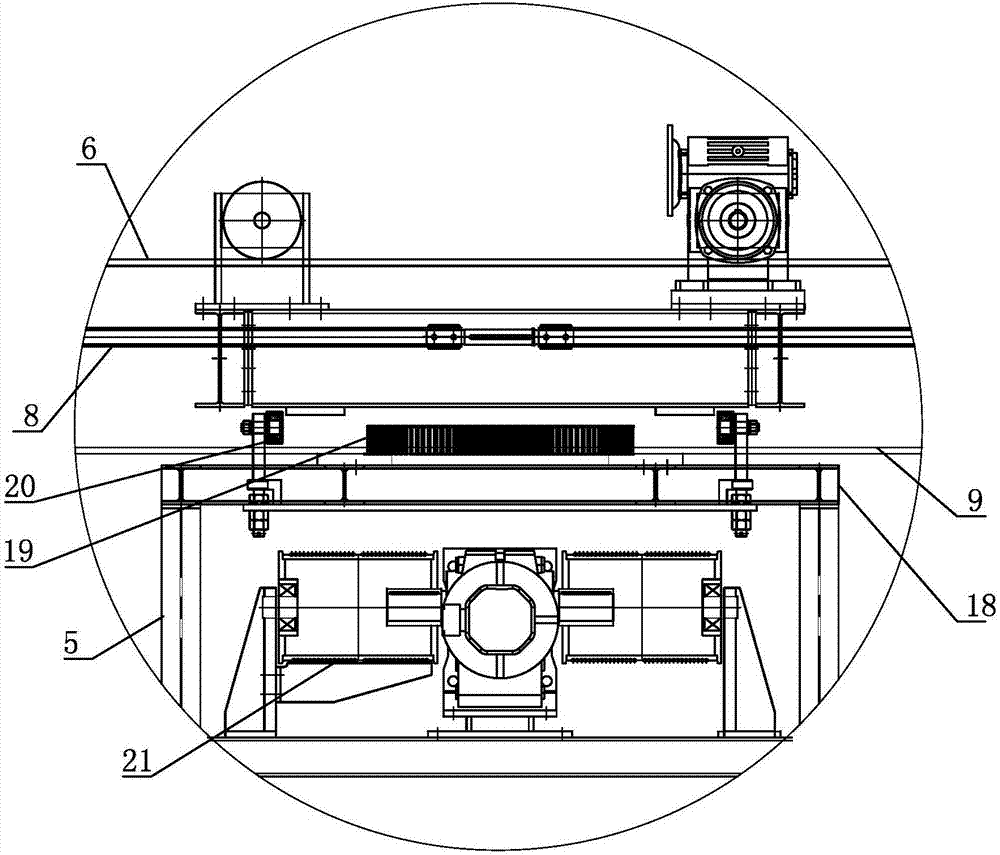

[0040] Such as figure 1 and figure 2 Commonly shown, the present invention also provides a comb-toothed three-dimensional garage, comprising a vertical beam 1, and several layers of parking comb racks 2 are fixedly installed on the vertical beam 1, and the parking comb rack 2 includes a The fixed portion 201 on the beam 1 and the cantilever portion 202 protruding from the vertical beam 1, the vertical beam 1 is located at the side of the cantilever portion 202 of the parking comb rack 2 is provided with a support beam 3, the tops of the vertical beam 1 and the support beam 3 are respectively Guide rails arranged in parallel are installed, and a traverse trolley 6 driven by a first power device is installed laterally on the two guide rails. The first power device includes a first transmission shaft 8 connected to a traverse motor 7. Usually, the first transmission The shaft 8 and the traversing motor 7 are connected by gear transmission or chain transmission, the first transm...

Embodiment 2

[0052] Such as Figure 10 As shown, the present invention also provides a comb-toothed three-dimensional garage, its structure is basically the same as that of embodiment one, the difference is that the comb-toothed three-dimensional garage is provided with two adjacent, two comb-toothed three-dimensional garage The vertical beams 1 are connected together, and the two cantilever parts 202 are arranged opposite to each other, so the structure is more reasonable. When the vehicle is stored, the force on both sides of the vertical beam 1 is balanced, and the stability is better.

[0053] Two comb-toothed three-dimensional garages share one vertical beam 1, which further reduces the use of the vertical beam 1, saves the use of section steel, and reduces production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com