Prestress cement mixing pile and construction method thereof

A technology of cement-soil mixing piles and construction methods, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of difficulty in exerting side friction resistance and increase of side friction resistance, and achieves simple and practical methods with high supporting capacity The effect of high pile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

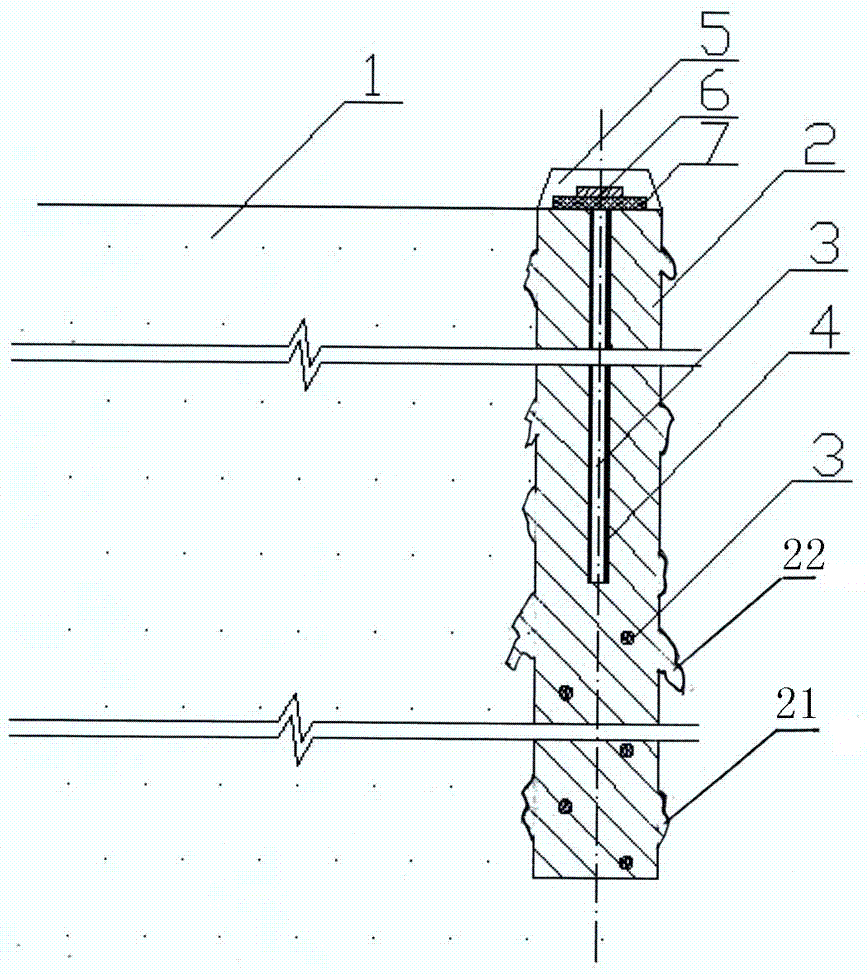

[0024] Such as figure 1 and figure 2 As shown, a prestressed soil-cement mixing pile is composed of soil-cement 1, and the surrounding wall of the pile body of the soil-cement mixing pile is formed by pressurizing and injecting incremental slurry to squeeze the surrounding soil of the bored pile wall. The pile body 2 is an irregular convex part connected together. The irregular convex part is an irregular semicircular sphere 21 protruding from the peripheral wall of the pile body, or a tree root-shaped convex part 22 .

[0025] Prestressed steel bars 3 are arranged in the pile body. The end of the prestressed reinforcement on the top of the pile is provided with an anchor 6 and a bearing plate 7 . The plastic casing 4 is provided on the 9-12m section of the prestressed steel bar downward from the top of the pile, and a sealing part is formed between the lower end of the plastic sleeve and the corresponding prestressed steel bar. The prestressed reinforcement at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com