A kind of antibacterial calligraphy and painting paper with controllable wetness and preparation method thereof

A technology of calligraphy and painting paper and antibacterial agent, which is applied in the field of papermaking, can solve the problems of poor antibacterial and anti-corrosion ink moistening properties, failure to meet quality standards, and low porosity of calligraphy and painting paper, and achieve improved paper strength, good physical strength indicators, and excellent biological properties. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

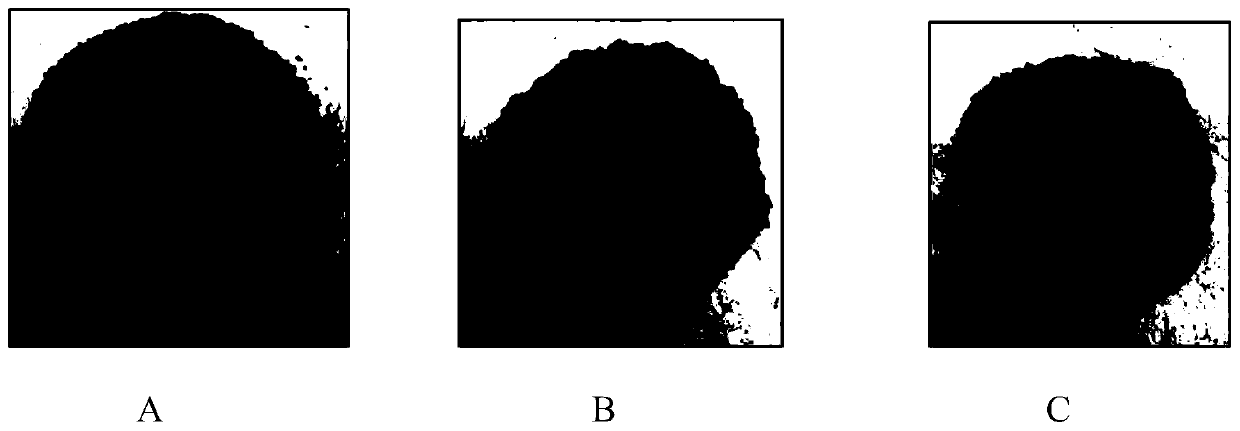

Image

Examples

Embodiment 1

[0069] (1) preparation of online slurry;

[0070] ① stock preparation

[0071] Wherein the bleached bamboo pulp fiber utilizes a hydropulper to disintegrate, and after screening and slag removal, beating is carried out, and the degree of beating is 30 ° SR to obtain bleached bamboo pulp for subsequent use; the asparagus fiber is disintegrated through a hydropulper, screened, Beating after slag removal, beating degree is 35 ° SR, obtains asparagus pulp, standby; Proportioning is bleached bamboo pulp in pulp tank: the mass ratio of asparagus pulp is 5:5;

[0072] ②Preparation of compound antibacterial agent

[0073] Chitosan (Jinan Tianben Biotechnology Co., Ltd., molecular weight 9.0×10) with deacetylation degree greater than 90% 4 ) was dissolved in a dilute acetic acid solution with a concentration of 3.0% by mass, and stirred for 3 hours; then according to the ratio of chitosan: inorganic antibacterial agent mass ratio of 1:1, adding silver ion inorganic antibacterial agen...

Embodiment 2

[0088] (1) preparation of online slurry;

[0089] ① stock preparation

[0090] Wherein the bleached bamboo pulp fiber utilizes a hydropulper to disintegrate, and after screening and slag removal, beating is performed, and the degree of beating is 35 ° SR to obtain bleached bamboo pulp for subsequent use; wherein the asparagus fiber is disintegrated through a hydropulper, screened , beating after slag removal, beating degree is 40 ° SR, obtains asparagus straw pulp, for subsequent use; Proportioning is bleached bamboo pulp in pulp tank: the mass ratio of asparagus straw pulp is 6:4;

[0091] ②Preparation of compound antibacterial agent

[0092] Chitosan (molecular weight is 9.0×10 4 ) was dissolved in a dilute acetic acid solution with a concentration of 3.5% by mass, stirred for 3 hours, and added a silver ion inorganic antibacterial agent (Japan Oasis 7600-Ag+25) according to the ratio of chitosan: inorganic antibacterial agent mass ratio of 1:1 , adjust the concentration ...

Embodiment 3

[0107] (1) preparation of online slurry;

[0108] ① stock preparation

[0109]Wherein the bleached bamboo pulp fiber utilizes a hydropulper to disintegrate, and is beaten after screening and slag removal, and the beating degree is 40°SR to obtain bleached bamboo pulp for subsequent use; wherein the asparagus fiber is disintegrated through a hydropulper, screened , beating after slag removal, beating degree is 35 ° SR, obtains asparagus straw pulp, for subsequent use; Proportioning is bleached bamboo pulp in pulp tank: the mass ratio of asparagus straw pulp is 7:3;

[0110] ②Preparation of compound antibacterial agent

[0111] Chitosan (molecular weight is 9.0×10 4 ) was dissolved in a dilute acetic acid solution with a concentration of 4.0% by mass, stirred for 3 hours, and added a silver ion inorganic antibacterial agent (Japan Oasis 7600-Ag+25) according to the ratio of chitosan: inorganic antibacterial agent mass ratio of 1:1 , adjust the concentration of the solution to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com