Method for synthesizing perfluorobut-2-ene by gas phase catalysis

A technology of butene and catalyst, which is applied in the field of organic synthesis, can solve the problems of easy decomposition, high price, and ignition temperature of only 180°C, and achieve the effects of convenient transportation and storage, reduced production cost, and increased possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

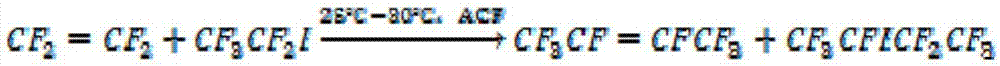

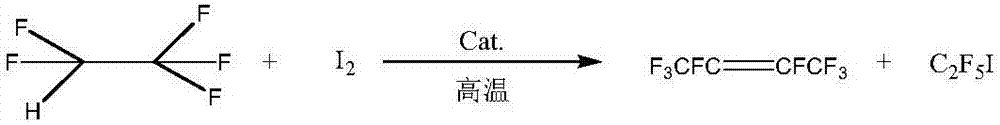

Method used

Image

Examples

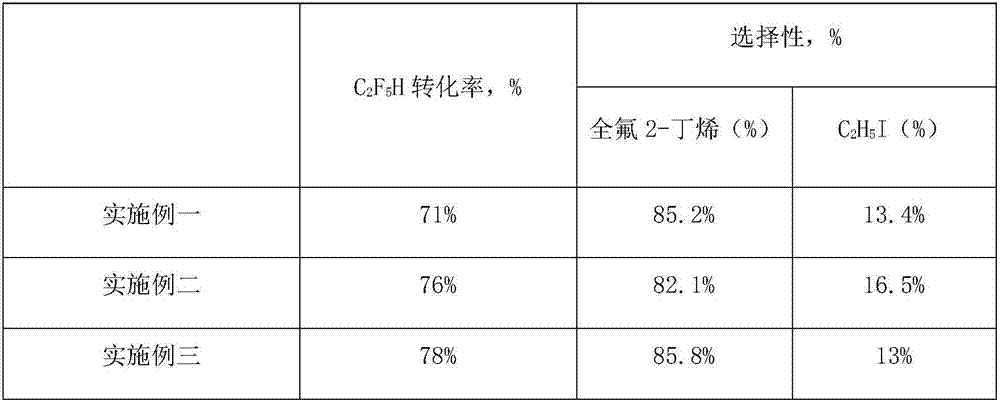

Embodiment 1

[0032] ① Catalyst preparation

[0033] Weigh 50 g of pretreated columnar coconut shell activated carbon, and then soak it in KF solution containing 10% of its mass fraction. After ultrasonicating the impregnating solution for 30 minutes, naturally impregnate for 8 hours, and then use a rotary evaporator to distill the impregnating solution under reduced pressure. After the impregnating solution is distilled, the catalyst is prepared.

[0034] ②Catalyst activation and pretreatment before reaction

[0035] Feed 150ml / min of N into the reactor equipped with 30ml catalyst 2 , and then the reactor was heated to 150° C. at a heating rate of 300° C. / h and kept for 4 hours to dry the catalyst. After drying for 4 hours, continue to heat the reactor to 500° C. at a heating rate of 300° C. / h and keep it for 4 hours to activate the catalyst. After the activation is completed, continue to heat the reactor to 550°C at a heating rate of 300°C / h and maintain a constant temperature. Adjust...

Embodiment 2

[0039] ① Catalyst preparation

[0040] Take the pretreated columnar coconut shell activated carbon 50g, then impregnate it in KNO containing 10% of its mass fraction 3in solution. After ultrasonicating the impregnating solution for 30 minutes, naturally impregnate for 8 hours, and then use a rotary evaporator to distill the impregnating solution under reduced pressure. After the impregnating solution is distilled, the catalyst is prepared.

[0041] ②Catalyst activation and pretreatment before reaction

[0042] Feed 150ml / min of N into the reactor equipped with 30ml catalyst 2 , and then the reactor was heated to 150° C. at a heating rate of 300° C. / h and kept for 4 hours to dry the catalyst. After drying for 4 hours, continue to heat the reactor to 500° C. at a heating rate of 300° C. / h and keep it for 4 hours to activate the catalyst. After the activation is completed, continue to heat the reactor to 550°C at a heating rate of 300°C / h and maintain a constant temperature. ...

Embodiment 3

[0046] ① Catalyst preparation

[0047] Weigh 50 g of pretreated columnar coconut shell activated carbon, and then impregnate it in Ce(NO 3 ) 3 ﹒ 6H 2 O and Ca(NO 3 ) 2 Mixed solution (mass ratio 1:1). After ultrasonicating the impregnating solution for 30 minutes, naturally impregnate for 8 hours, and then use a rotary evaporator to distill the impregnating solution under reduced pressure. After the impregnating solution is distilled, the catalyst is prepared.

[0048] ②Catalyst activation and pretreatment before reaction

[0049] Feed 150ml / min of N into the reactor equipped with 30ml catalyst 2 , and then the reactor was heated to 150° C. at a heating rate of 300° C. / h and kept for 4 hours to dry the catalyst. After drying for 4 hours, continue to heat the reactor to 500° C. at a heating rate of 300° C. / h and keep it for 4 hours to activate the catalyst. After the activation is completed, continue to heat the reactor to 600°C at a heating rate of 300°C / h and keep th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com