Ball producing process and ball producing system in process of producing inorganic fibers by using red mud

A technology of inorganic fiber and red mud, applied in the manufacture of tools, glass manufacturing equipment, etc., can solve the problems of unstable product quality, high cost of raw materials, low batching accuracy, etc., to facilitate programmed operation, reduce breakage rate, and batching accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

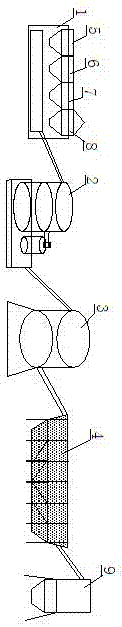

Method used

Image

Examples

Embodiment 1

[0038] Example 1 A ball-making process in the process of producing inorganic fibers from red mud

[0039] Specific steps are as follows:

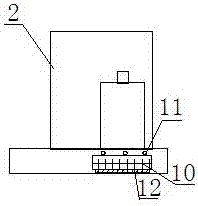

[0040](1) Add the red mud with a water content of 14% or less to the red mud silo of the four-bin batching machine, and at the same time add the curing agent cement, the acidity coefficient regulator particle size less than 180 mesh silica powder, and the solvent-assisted limestone crushed stone respectively Add the corresponding auxiliary material silo of the four-bin batching machine;

[0041] (2) The red mud, curing agent, acidity coefficient regulator and co-solvent in the silo are sent to the crushing mixer through the conveyor at a mass ratio of 1:0.13:0.13:0.04, and the feed of the crushing mixer Humidification devices are installed at both the mouth and the discharge port. When the red mud, curing agent, acidity coefficient regulator and co-solvent enter the crushing mixer, the humidity is 8.5%, and the humidity of the material at ...

Embodiment 2

[0044] Example 2 A ball-making process in the process of producing inorganic fibers from red mud

[0045] Specific steps are as follows:

[0046] (1) Add the red mud with a water content of 14% or less into the red mud silo of the batching machine, and at the same time add the curing agent cement, the basalt crushed stone with a particle size of the acidity coefficient regulator less than 1cm and the cosolvent fluorspar crushed stone Add the corresponding auxiliary material silo of the batching machine respectively;

[0047] (2) The red mud, curing agent, acidity coefficient regulator and co-solvent in the silo are sent to the crushing mixer through the conveyor at a mass ratio of 1:0.11:0.3:0.035, and the feed of the crushing mixer Humidification devices are installed at both the outlet and the discharge port, so that the humidity of red mud, curing agent, acidity coefficient regulator and co-solvent entering the crushing mixer is 9.2%, and the humidity of the material at th...

Embodiment 3

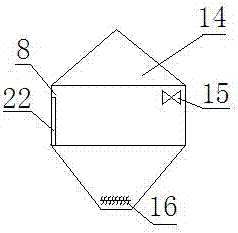

[0049] (4) Send the ball block material to the ball warehouse box through the conveyor, solidify in the box, and dry in the shade. When the mechanical strength of the ball block material is 15 kg / cm 2 , it is sent out through the ball block outlet of the ball warehouse box. Example 3 A ball making process in the process of producing inorganic fibers from red mud

[0050] Specific steps are as follows:

[0051] (1) Add red mud with a water content less than or equal to 14% to the red mud silo of the four-bin batching machine, and at the same time add the curing agent cement, the acidity coefficient regulator particle size less than 180 mesh silica powder and the co-solvent to the four-bin batching machine The corresponding auxiliary material silo of the machine;

[0052] (2) The red mud, curing agent, acidity coefficient regulator and co-solvent fluorspar crushed stone in the silo are sent to the crushing mixer through the conveyor at the mass ratio of 1:0.145:0.14:0.045, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com