Charging method and system for industrial production

A material feeding and material tank technology, which is applied in the material feeding field of industrial production, can solve problems such as increased fuel consumption per unit product, increased slag balls, and unbalanced melting, so as to achieve fast and balanced melting process, increase fiber formation rate, reduce The effect of pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

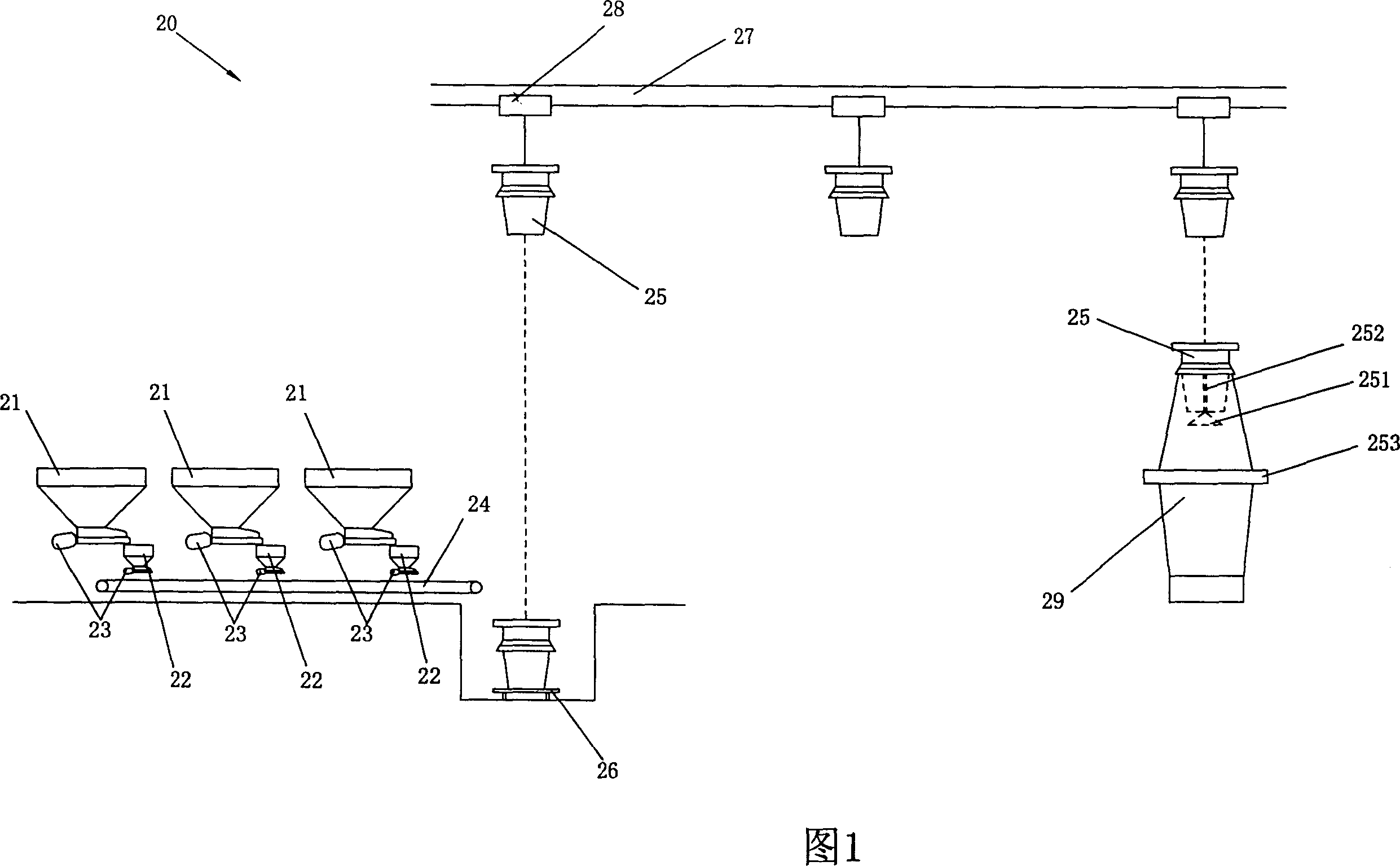

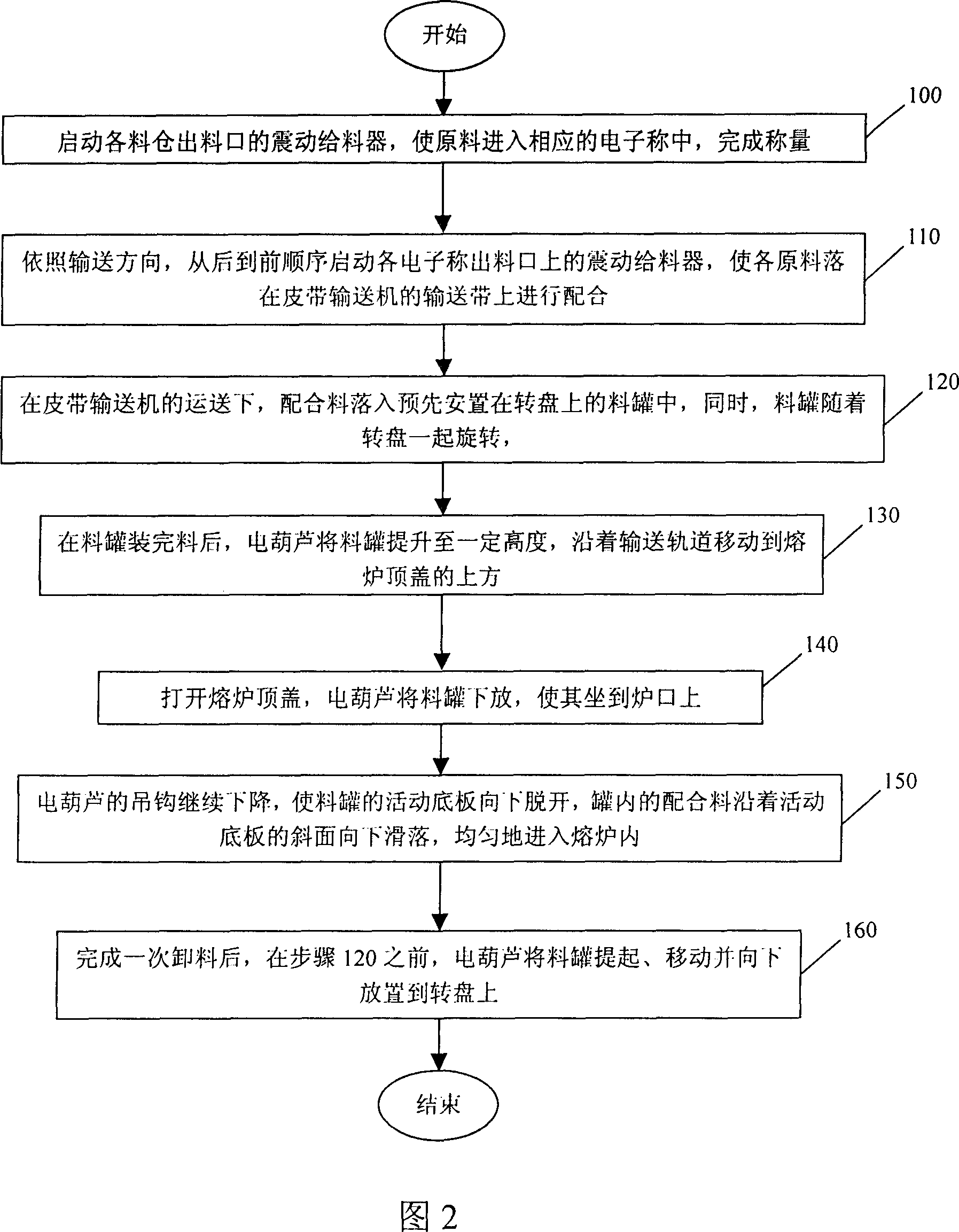

[0027] As shown in Figure 1, the mineral wool production loading system 20 of the embodiment of the present invention includes three silos 21 (the number of silos can be set according to needs), three electronic scales 22, six vibrating feeders 23, one Belt conveyor 24, a material tank 25, a turntable 26, a delivery track 27, an electric hoist 28 connected with the material tank, and a melting furnace 29 upwards to open the top cover.

[0028] As shown in the figure, three hoppers 21 are arranged side by side on one side of the belt conveyor 24, and below the discharge port is the feed port of the corresponding electronic scale 22, and the discharge port of each electronic scale 22 is located on the belt conveyor 24. above the conveyor belt. A vibrating feeder 23 is arranged on the discharge port of each feed bin 21 and the electronic scale 22 . The turntable 26 is arranged below the front end (ie, the end in the conveying direction) of the belt conveyor 24 . The feed tank 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com