Vertical flow coagulation sedimentation and air flotation dual-purpose tank

A coagulation-sedimentation, vertical-flow technology, applied in the direction of flocculation/sedimentation water/sewage treatment, flotation water/sewage treatment, chemical instruments and methods, etc., can solve the problem of increasing the workload and difficulty of the treatment process, and the inability to fine flocs Separation, sludge discharge and blockage, etc., to improve coagulation and flocculation effects, solve bottom sludge deposition, and optimize chemical mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

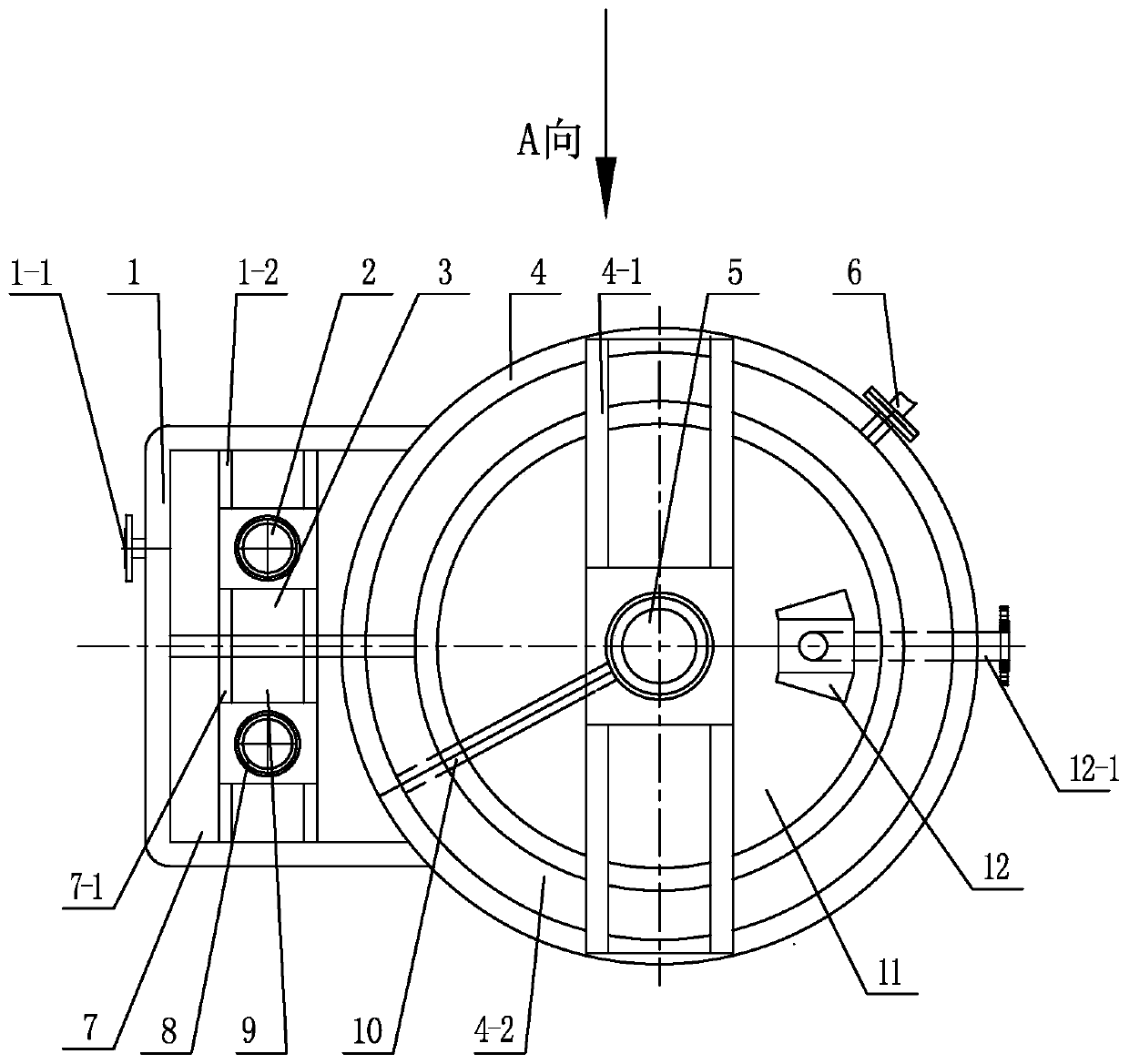

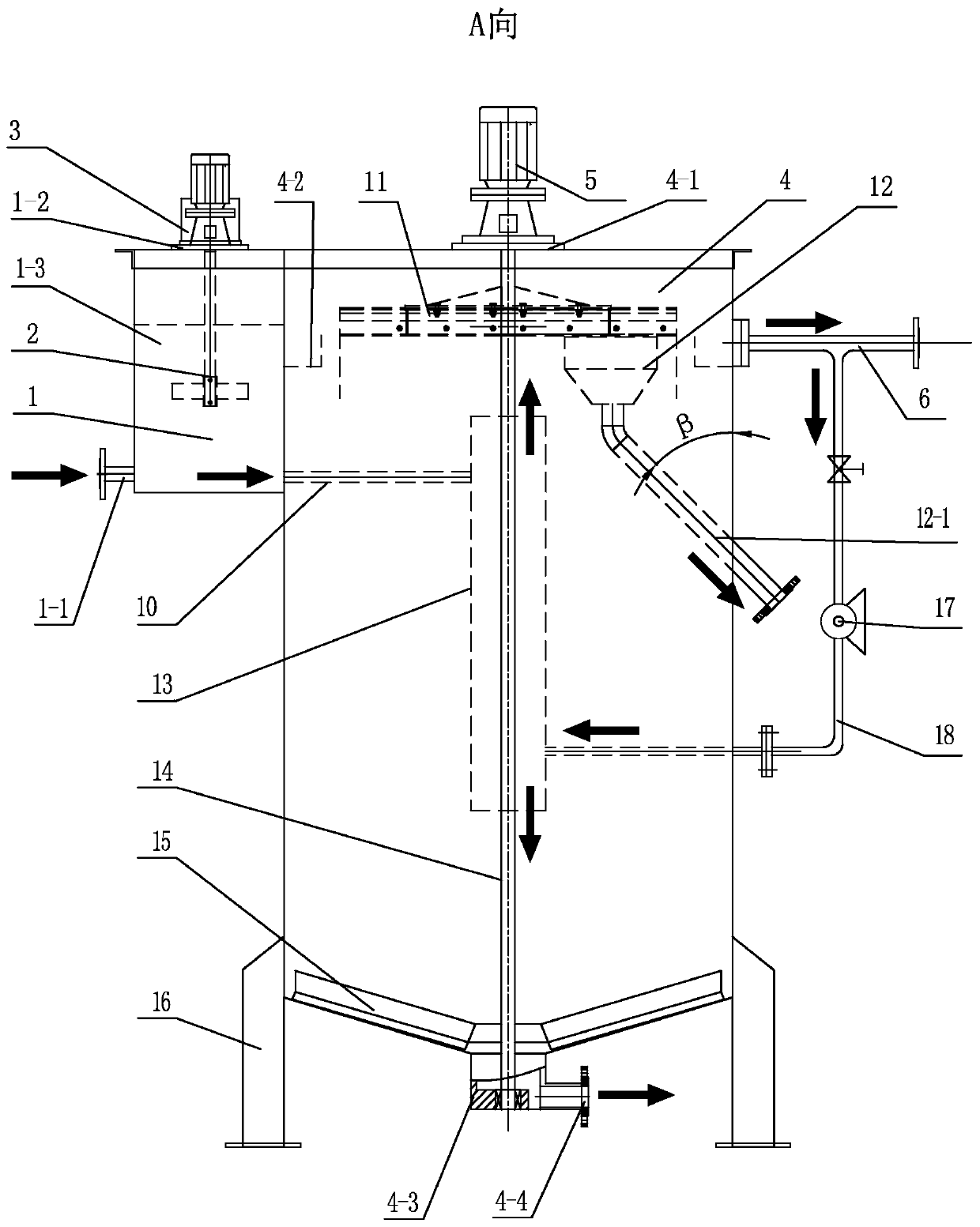

[0014] see figure 1 , 2 As shown, the vertical flow type coagulation sedimentation and air flotation dual purpose tank of the present invention includes a cylinder body 4, a coagulation tank 1 and a flocculation tank 7 located on the outer side of the cylinder body 4, a cylinder body 4 and a coagulation tank 1 and flocculation The tank 7 can be set independently or integrated. The coagulation tank 1 and the flocculation tank 7 can be located in the upper part of the cylinder 4. The lower part of the coagulation tank 1 is provided with an inlet 1-1 for introducing waste water. Sent to coagulation tank 1 for processing. see figure 1 , 2 As shown, the coagulation tank 1 of the present invention is equipped with a coagulant dosing box 3 and a coagulation stirrer 2 for mixing wastewater, and the coagulant can be added to the coagulation tank in batches through the coagulant dosing box 3 1, and through the coagulation stirrer 2 to fully mix the waste water and the coagulant. The coag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com