Catalyst used for purifying volatile organic compound and preparation method of catalyst

A volatile organic compound and catalyst technology, which is applied in the field of volatile organic compound purification catalyst and its preparation, can solve the problems of lengthy preparation process, high noble metal loading, and low noble metal loading, and achieve simple process, good low-temperature activity, The effect of excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

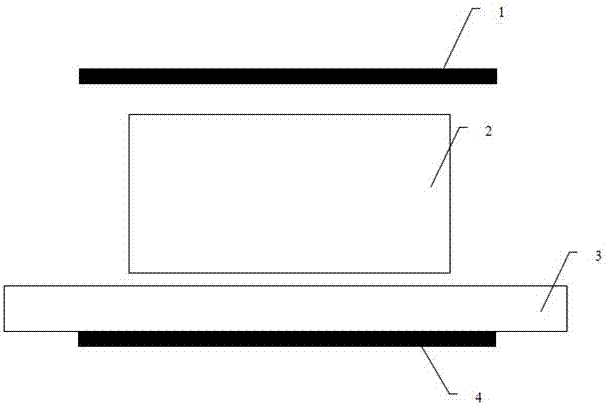

Image

Examples

Embodiment 1

[0045] (1) Coating of modified alumina on cordierite honeycomb ceramic substrate

[0046] The mixed solution of iron salt, cobalt salt, nickel salt is mixed with the water-soluble colloid of aluminum hydroxide, and described iron salt, cobalt salt, nickel salt are Fe(NO 3 ) 3 9H2 O, Co(AC) 3 4H 2 O, Ni(NO 3 ) 4 ·6H 2 O, specifically weigh 22.5231g Fe(NO 3 ) 3 9H 2 O, 13.8872g Co(AC) 3 4H 2 O, 16.0482g Ni(NO 3 ) 4 ·6H 2 O was dissolved in 20ml of deionized water, and mixed with a colloid containing 20ml of deionized water and 65.0166g of aluminum hydroxide, and magnetically stirred; in the prepared mixed solution, the molar ratio of iron, cobalt, nickel, and aluminum was 1:1 :1:7;

[0047] Immerse cordierite honeycomb ceramics in the mixture of the above-mentioned salt solution and colloid for 20 minutes, and then coat the modified alumina. ℃ for 3 hours to obtain a cordierite honeycomb ceramic substrate coated with modified alumina.

[0048] (2) Discharge stren...

Embodiment 2

[0063] (1) Coating of modified alumina on cordierite honeycomb ceramic substrate

[0064] The mixed solution of iron salt, cobalt salt, nickel salt is mixed with the water-soluble colloid of aluminum hydroxide, and described iron salt, cobalt salt, nickel salt are Fe(NO 3 ) 3 9H 2 O, Co(AC) 3 4H 2 O, Ni(NO 3 ) 4 ·6H 2 O, specifically weigh 39.9530g Fe(NO 3 ) 3 9H 2 O, 24.6339g Co(AC) 3 4H 2 O, 28.4672g Ni(NO 3 ) 4 ·6H 2 O was dissolved in 25ml of deionized water, mixed with colloid containing 15ml of deionized water and 60.4111g of aluminum hydroxide, and magnetically stirred; in the prepared mixed solution, the molar ratio of iron, cobalt, nickel, and aluminum was 1.5:1.5: 1.5:5.5;

[0065] Immerse cordierite honeycomb ceramics in the mixture of the above-mentioned salt solution and colloid for 25 minutes, and then coat the modified alumina. ℃ for 2 hours to obtain a cordierite honeycomb ceramic matrix coated with modified alumina.

[0066] (2) Discharge stre...

Embodiment 3

[0081] (1) Coating of modified alumina on cordierite honeycomb ceramic substrate

[0082]The mixed solution of iron salt, cobalt salt, nickel salt is mixed with the water-soluble colloid of aluminum hydroxide, and described iron, cobalt, nickel salt are Fe(NO 3 ) 3 9H 2 O, Co(AC) 3 4H 2 O, Ni(NO 3 ) 4 ·6H 2 O, specifically weigh 59.8240g Fe(NO 3 ) 3 9H 2 O, 36.8859g Co(AC) 3 4H 2 O, 42.6257g Ni(NO 3 )4·6H 2 O was dissolved in 30ml of deionized water, mixed with a colloid containing 10ml of deionized water and 49.3404g of aluminum hydroxide, and magnetically stirred; in the prepared mixed solution, the molar ratio of iron, cobalt, nickel, and aluminum was 2:2: 2:4;

[0083] Immerse cordierite honeycomb ceramics in the mixture of the above-mentioned salt solution and colloid for 30 minutes, and then coat the modified alumina. ℃ for 1 h to obtain a cordierite honeycomb ceramic substrate coated with modified alumina.

[0084] (2) Discharge strengthening pretreatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com