Activated carbon/carbon nanotube/graphene composite material and preparation method and application thereof

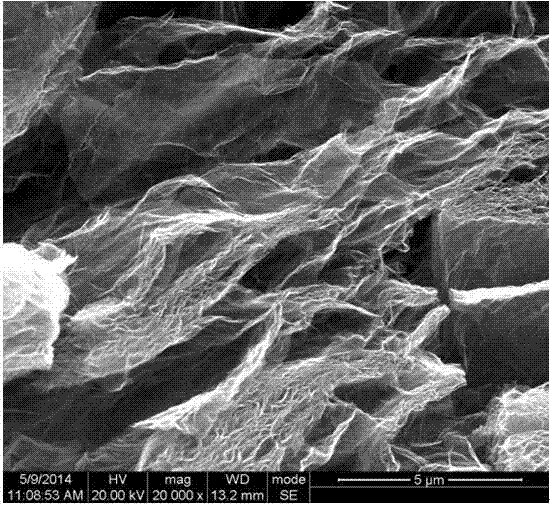

A technology of carbon nanotubes and composite materials, which is applied in the field of activated carbon/carbon nanotubes/graphene composite materials and preparation, can solve problems such as difficulty in exerting capacitance performance and easy agglomeration of graphene sheets, and achieve excellent electrochemical performance and improved Mass energy density, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

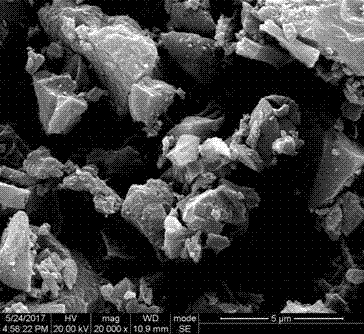

[0041] Example 1 Activated carbon / carbon nanotube / graphene composite material for lithium ion and preparation method thereof

[0042] It includes the following steps:

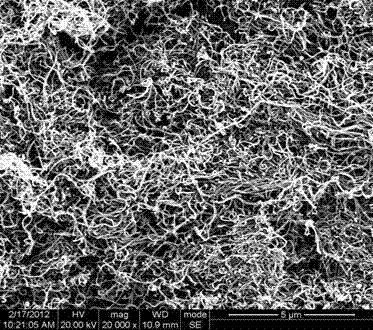

[0043] S1. Pulping: uniformly disperse graphene oxide in deionized water, ultrasonically peel it into layers of graphene oxide, and configure it into a uniform dispersion of 2mg / ml; evenly disperse carbon nanotubes in deionized water, add 1% The surface active agent polyvinylpyrrolidone K30 (PVP-K30) is configured into a uniformly dispersed suspension of 2mg / ml, and it is uniformly dispersed by ultrasound;

[0044] S2. Mixing: Take 85ml of the above two slurries according to a certain ratio of graphene oxide slurry, take 5ml of carbon nanotubes, 20mg of activated carbon, mix (AC:CNTs:GO=10:5:85), and make carbon nanotubes. Conductive agent, supporting barrier agent, and ultrasonic to make the mixing uniform. Preparation of activated carbon / carbon nanotube / graphene composite material;

[0045] S3 Vacuum filtration: Us...

Embodiment 2

[0050] Example 2 An activated carbon / carbon nanotube / graphene composite material for lithium ion and its preparation method

[0051] It includes the following steps:

[0052] S1. Pulping: uniformly disperse graphene oxide in deionized water, ultrasonically peel it into layers of graphene oxide, and configure it into a uniform dispersion of 2mg / ml; evenly disperse carbon nanotubes in deionized water, add 1% The surface active agent polyvinylpyrrolidone K30 (PVP-K30) is configured into a uniformly dispersed suspension of 2mg / ml, and it is uniformly dispersed by ultrasound;

[0053] S2. Mixing: Take 85ml of the above two slurries according to a certain ratio of graphene oxide slurry, take 5ml of carbon nanotubes, and 40mg of activated carbon, mix (AC:CNTs:GO=20:5:75), and make carbon nanotubes. Conductive agent, supporting barrier agent, and ultrasonic to make the mixing uniform. Preparation of activated carbon / carbon nanotube / graphene composite material;

[0054] S3 Vacuum filtration:...

Embodiment 3

[0059] Example 3 An activated carbon / carbon nanotube / graphene composite material for lithium ion and its preparation method

[0060] It includes the following steps:

[0061] S1. Pulping: uniformly disperse graphene oxide in deionized water, ultrasonically peel it into layers of graphene oxide, and configure it into a uniform dispersion of 2mg / ml; evenly disperse carbon nanotubes in deionized water, add 1% The surface active agent polyvinylpyrrolidone K30 (PVP-K30) is configured into a uniformly dispersed suspension of 2mg / ml, and it is uniformly dispersed by ultrasound;

[0062] S2. Mixing: Take 85ml of the above two slurries according to a certain ratio of graphene oxide slurry, take 5ml of carbon nanotubes, 60mg of activated carbon, mix (AC:CNTs:GO=30:5:65), and make carbon nanotubes. Conductive agent, supporting barrier agent, and ultrasonic to make the mixing uniform. Preparation of activated carbon / carbon nanotube / graphene composite material;

[0063] S3 Vacuum filtration: Use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com