Wave plate screw assembly

A screw and assembly technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve problems such as inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The foregoing and other technical content, features and functions of the present invention will be clearly understood in the following detailed description of preferred embodiments with reference to the drawings.

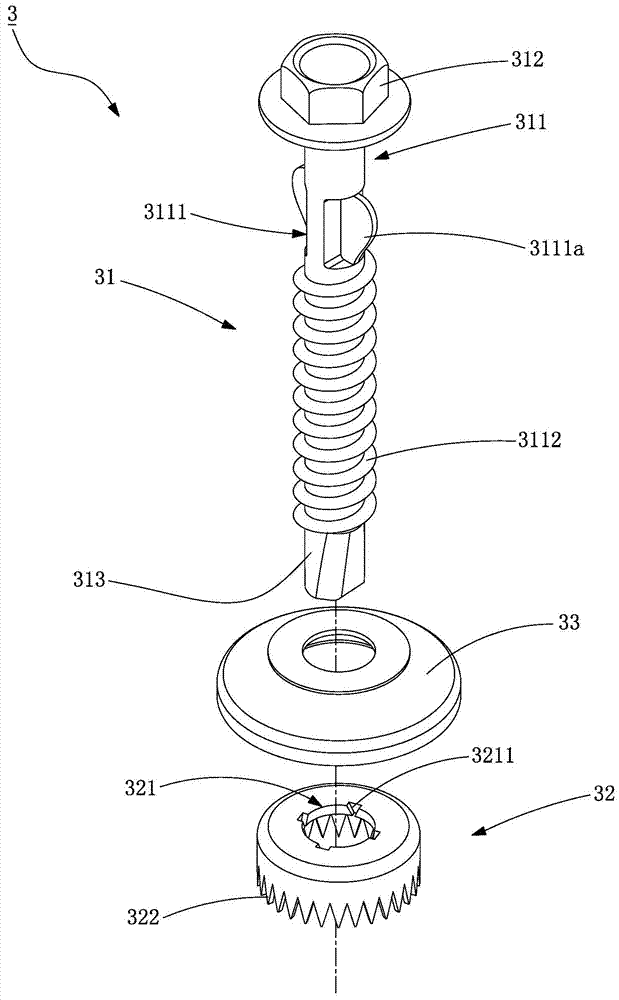

[0047] refer to image 3 , the first preferred embodiment of the corrugated plate screw assembly 3 of the present invention, the corrugated plate screw assembly 3 includes a locking part 31, a hole reaming part 32 that can be sleeved on the locking part 31, and a The washer 33 on the locking member 31; wherein, the locking member 31 has a rod body 311, a screw head 312 arranged on the rod body 311, and a screw head 312 opposite to the screw head 312 and arranged at the other end of the rod body 311 The locking part 313, and the aforementioned rod body 311 is divided into a connecting part 3111 connecting the screw head 312, and a plurality of screw teeth 3112 extending from the connecting part 3111 to the locking part 313, and the connecting part 3111 has at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com