Ferrite high temperature steel

A heat-resistant steel and ferrite technology, applied in the field of ferritic heat-resistant steel, can solve the problems of complex precipitation process, and achieve the effect of simple alloy heat treatment process, operability, and controllable size or shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A nanoscale Ni 16 m 6 Si 7 (M=Ti, Nb) precipitated phase strengthened ferritic heat-resistant steel and its preparation method. The chemical composition and content of the high-chromium ferritic heat-resistant steel are: 19wt.% of Cr; 3wt.% of Ni; 0.3wt.% of Mn; 3wt.% of Si; 1.5wt.% of Ti; C is 0.08wt.%; B is 0.05wt.%; the balance is Fe and unavoidable impurities.

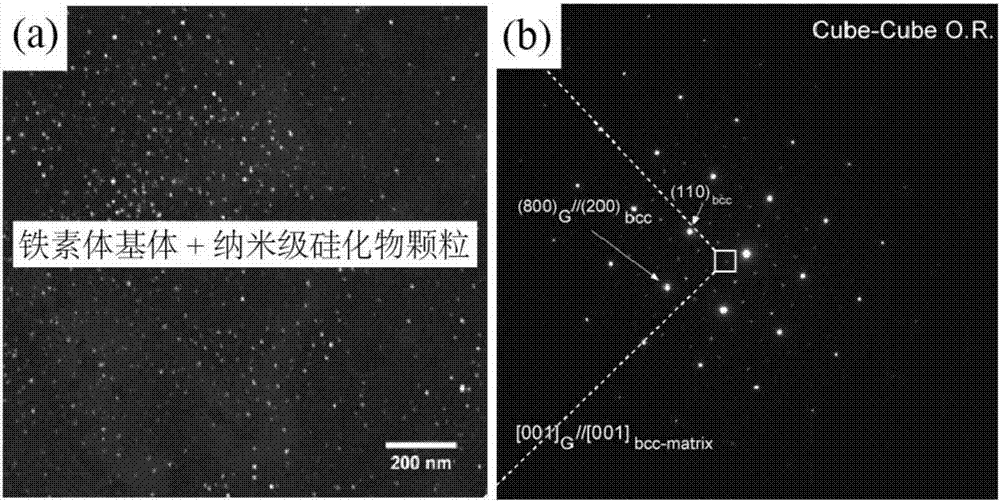

[0043] According to the chemical composition and content of the high-chromium ferritic heat-resistant steel, the ingredients are mixed, the alloy is melted in a vacuum arc melting furnace, hot-rolled into a plate, and then aged at 660 ° C for 20 minutes, and air-cooled. Describe Ni 16 m 6 Si 7 (M=Ti, Nb) strengthened ferritic heat-resistant steel. figure 1 for nanoscale Ni 16 m 6 Si 7 Typical microstructure and diffraction pattern of (M=Ti,Nb) precipitate-strengthened ferritic heat-resistant steel, showing that Ni 16 m 6 Si 7 (M=Ti, Nb) are nano-scale dispersed particles and have a coherent rel...

Embodiment 2

[0045] A nanoscale Ni 16 m 6 Si 7 (M=Ti, Nb) precipitate-strengthened element heat-resistant steel and its preparation method. The chemical composition and content of the high-chromium ferritic heat-resistant steel are: Cr is 22wt.%; Ni is 1.8wt.%; Mn is 0.5wt.%; Si is 3.3wt.%; Nb is 1.3wt.%. %; C is 0.05wt.%; B is 0.05wt.%; the balance is Fe and unavoidable impurities.

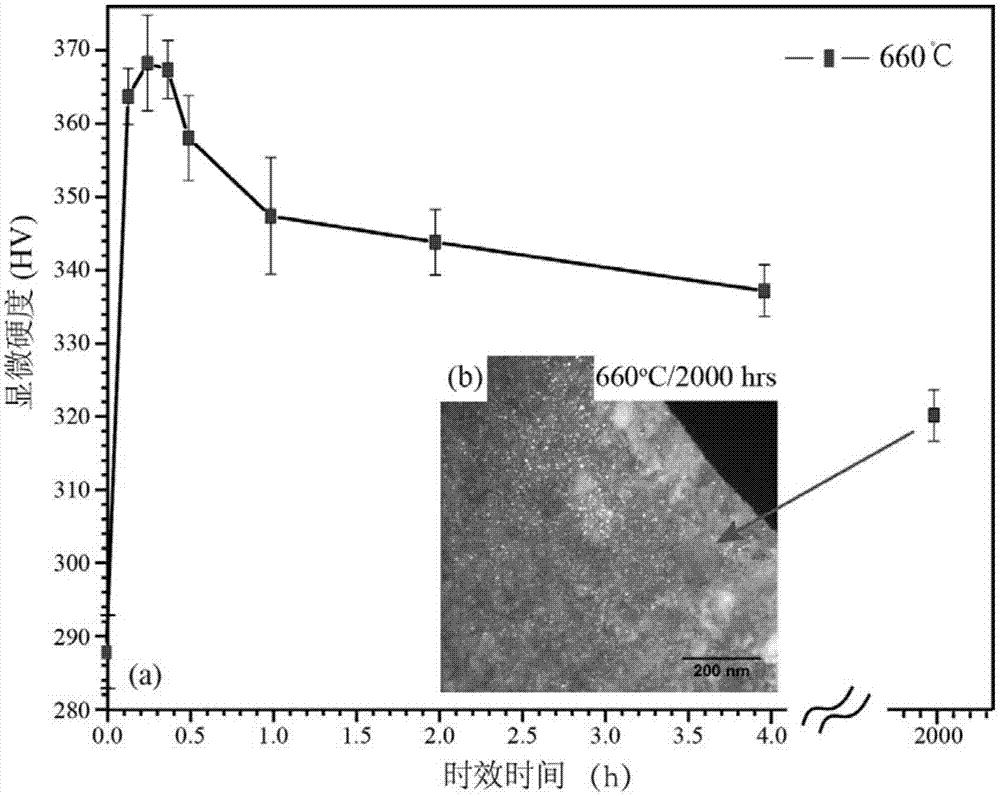

[0046] According to the chemical composition and content of the high-chromium ferritic heat-resistant steel, the ingredients are mixed, the alloy is melted in a vacuum arc melting furnace, hot-rolled into a plate, and then aged at 760°C for 30 minutes, and air-cooled to obtain the obtained product. Describe Ni 16 m 6 Si 7 (M=Ti, Nb) Precipitation-strengthened ferritic heat-resistant steel. figure 2 Hardness versus aging time of the 22Cr ferritic heat-resistant steel prepared for Example 2 after aging at 660°C, Ni 16 m 6 Si 7 (M=Ti, Nb) precipitation makes the Vickers hardness of the alloy steel fro...

Embodiment 3

[0048] A nanoscale Ni 16 m 6 Si 7(M=Ti, Nb) particle reinforced ferritic heat-resistant steel and its preparation method. The chemical composition and content of the high-chromium ferritic heat-resistant steel are: Cr is 18wt.%; Ni is 2.5wt.%; Mn is 0.5wt.%; Si is 2wt.%; Ti is 0.85wt.% ; C is 0.07wt.%; B is 0.05wt.%; the balance is Fe and unavoidable impurities.

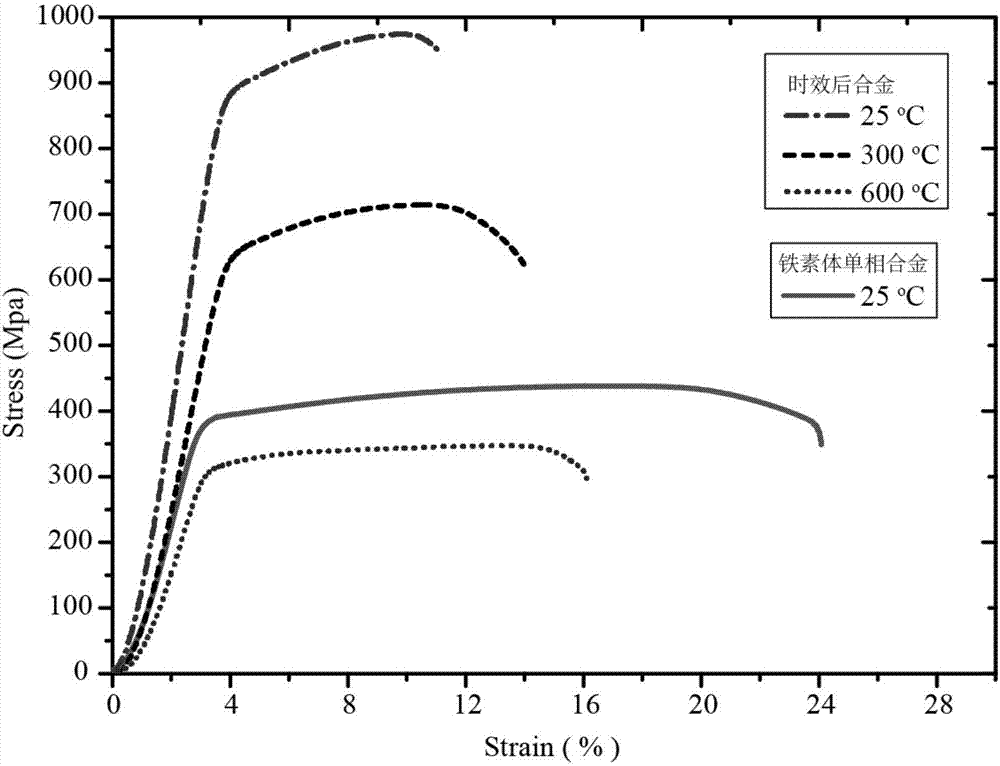

[0049] According to the chemical composition and content of the high-chromium ferritic heat-resistant steel, the ingredients are mixed, the alloy is melted in a vacuum arc melting furnace, hot-rolled into a plate, and then aged at 660 ° C for 30 minutes, and air-cooled. Describe Ni 16 m 6 Si 7 (M=Ti, Nb) precipitation strengthened ferritic heat-resistant steel. image 3 The room temperature and high temperature tensile curve of the 19Cr ferritic heat-resistant steel prepared for the implementation of case 3 shows that Ni 16 m 6 Si 7 The precipitation of (M=Ti, Nb) phase increases the room temperature ultima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com