Fermented seedless yellow-skinned green plum fruit wine and production method thereof

A green plum fruit wine and a production method technology are applied in the field of fermented fruit wine, which can solve the problems of single taste, single nutritional value component and single health care function, and achieve the effects of good health care effect, rich compound fruit aroma, more mellow wine body and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

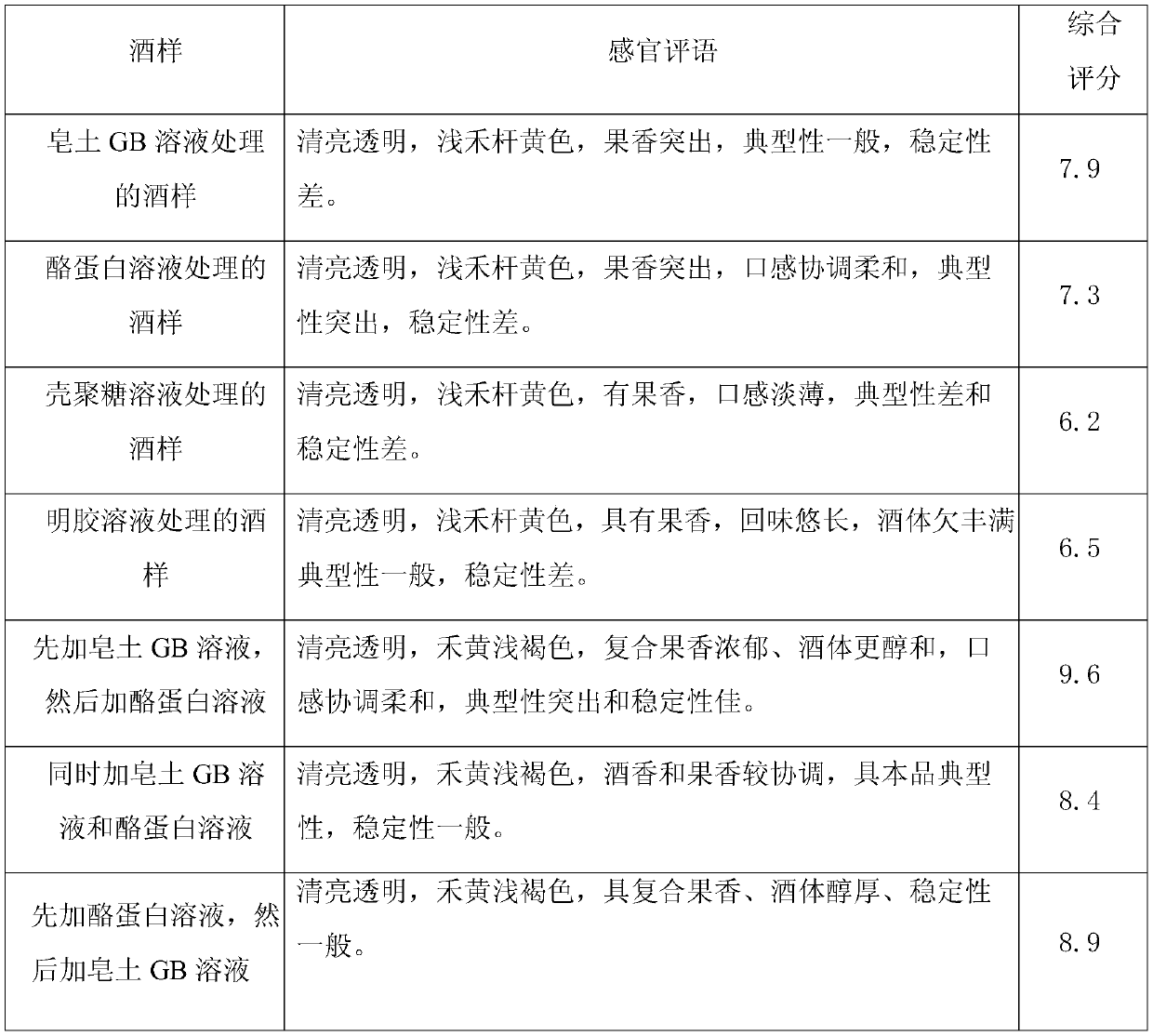

[0059] 1, the preparation method of the bentonite GB solution involved in the present invention is as follows:

[0060] Mix bentonite GB (Shanghai Dingtang International Trade Co., Ltd.) and warm water at 35-40°C at a ratio of 1g: 18mL, and wait until bentonite GB is completely dissolved to obtain a bentonite GB solution.

[0061] 2, the preparation method of the casein solution involved in the present invention is as follows:

[0062] First mix casein (French Raman Group) and 2.5-3% (v / v) food-grade citric acid solution at a ratio of 1g: 2.5mL, and then dissolve it in a water bath at a temperature of 48°C-51°C. The protein is completely dissolved to obtain a casein solution.

Embodiment 1

[0064] (1) Broken: Mix the selected and cleaned seedless yellow skin and green plum according to the mass ratio of 2.1:1.3 and then crush to obtain fruit mash;

[0065] (2) Three times of enzymatic hydrolysis: on the basis of the preliminary test, first add pectinase EX-V (Shanghai Jietu Industry and Trade Co., Ltd.) to carry out an enzymatic hydrolysis at 18.8°C for 4.5 hours to obtain the first enzymatic hydrolysis Solution, wherein, pectinase EX-V is added according to the final concentration of 23mg / L in enzymolysis system; ℃ for the second enzymatic hydrolysis, enzymatic hydrolysis for 6 hours, to obtain the second enzymatic hydrolysis solution, in which protease was added at a final concentration of 31 mg / L in the enzymatic hydrolysis system; then pectinase EXTRAZYME was added TM (French Raman Group) carried out three enzymatic hydrolysis at 19.4°C for 5 hours to obtain the third enzymatic hydrolysis solution, in which pectinase EXTRAZYME TM Add according to the final c...

Embodiment 2

[0072] (1) Broken: Mix the selected and cleaned seedless yellow skin and green plum according to the mass ratio of 2.3:1.4 and then crush to obtain fruit mash;

[0073] (2) Three times of enzymatic hydrolysis: on the basis of the preliminary test, first add pectinase EX-V (Shanghai Jietu Industry and Trade Co., Ltd.) to carry out an enzymatic hydrolysis at 19.1°C for 4.8 hours to obtain the first enzymatic hydrolysis Solution, wherein, pectinase EX-V is added according to the final concentration of 24.5mg / L in the enzymolysis system; then add food-grade neutral protease heshibi-18 (Ningxia Heshibi Biotechnology Co., Ltd.) Second enzymatic hydrolysis, enzymatic hydrolysis for 7 hours, to obtain the second enzymatic hydrolysis solution, in which, protease was added at a final concentration of 33 mg / L in the enzymatic hydrolysis system; then pectinase EXTRAZYME was added TM Carry out three enzymatic hydrolysis at 19.9°C for 5.5 hours to obtain the third enzymatic hydrolysis solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com