Tar gasification circulating device and gasification system

A technology of coke gasification and circulation device, which is applied in gasification process, coking carbon-containing materials, coke oven and other directions, can solve the problems of secondary pollution, equipment liquid recovery and large circulation device, can not work continuously, etc. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

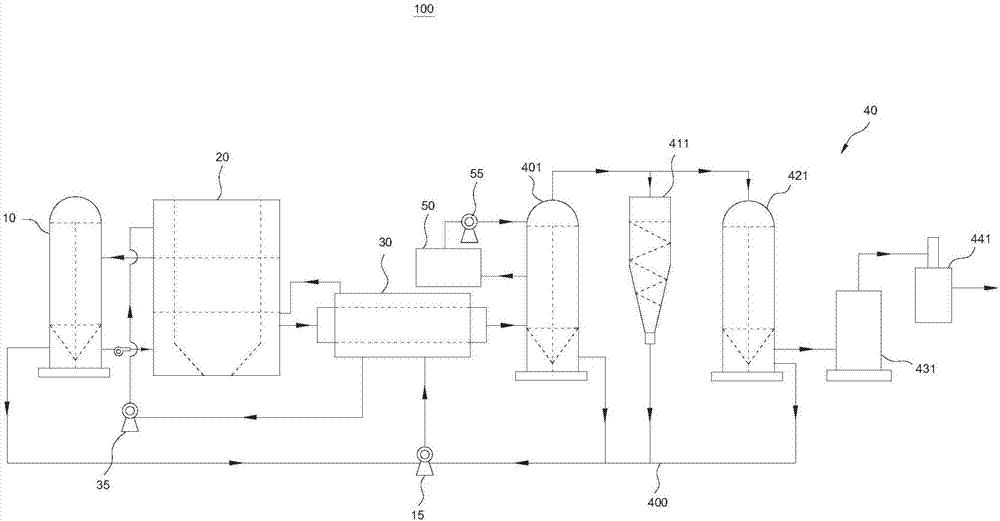

[0031] Please refer to figure 1, this embodiment provides a tar gasification cycle device, which includes a separator 10 for connecting to a gasifier 20 , a tar gasification pipe 30 for gasifying tar produced by the gasifier 20 , and a filtering device 40 .

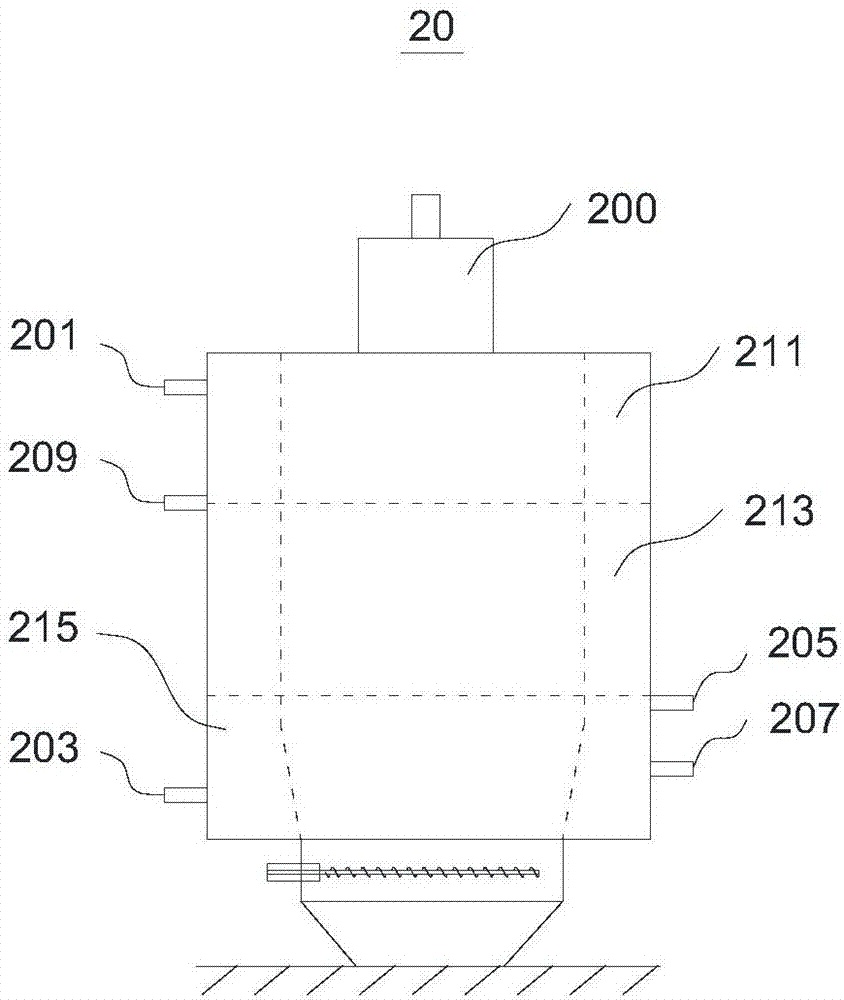

[0032] Further, please refer to the attached figure 2 , the gasification furnace 20 includes a drying chamber 211 , a pyrolysis chamber 213 and a gasification chamber 215 . The material enters the gasification furnace 20 from the feed port 200, and passes through the drying chamber 211, the pyrolysis chamber 213 and the gasification chamber 215 in sequence, wherein incompletely combusted mixed gas will be generated in the drying chamber 211 and the pyrolysis chamber 213 , including tar and water vapour.

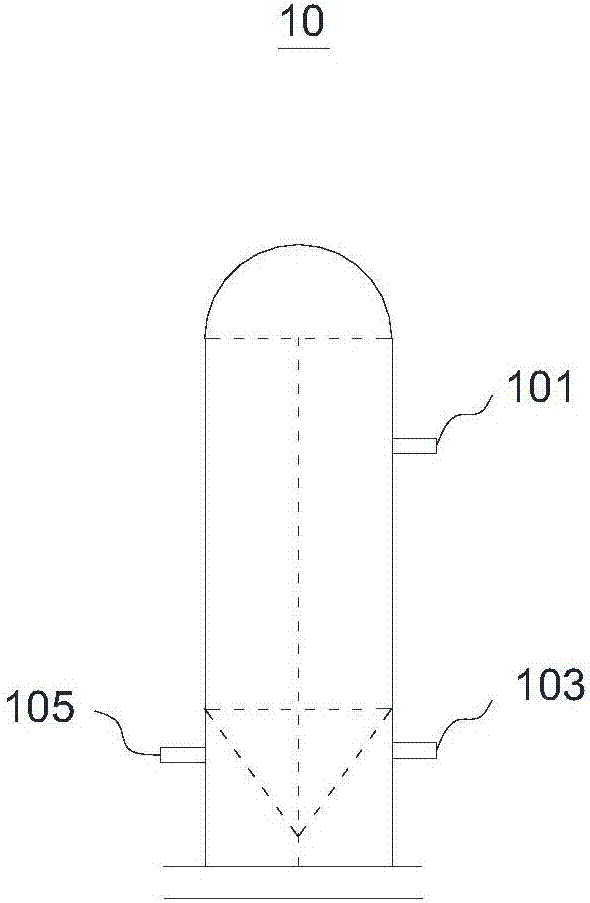

[0033] Further, please refer to the attached image 3 , The tar gasification cycle device includes a separator 10. The separator 10 is mainly used for reusing the incompletely combusted gases produced in the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com