Inorganic mineral fiber spray rock mortar and using method thereof

An inorganic mineral fiber and rock mud technology, which is applied in the fields of fireproof materials, sound insulation, and thermal insulation inside and outside of wall building structures, can solve the problems of short service life of materials, poor UV resistance, and many joints in thermal insulation materials. High fire rating, good decorative effect, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

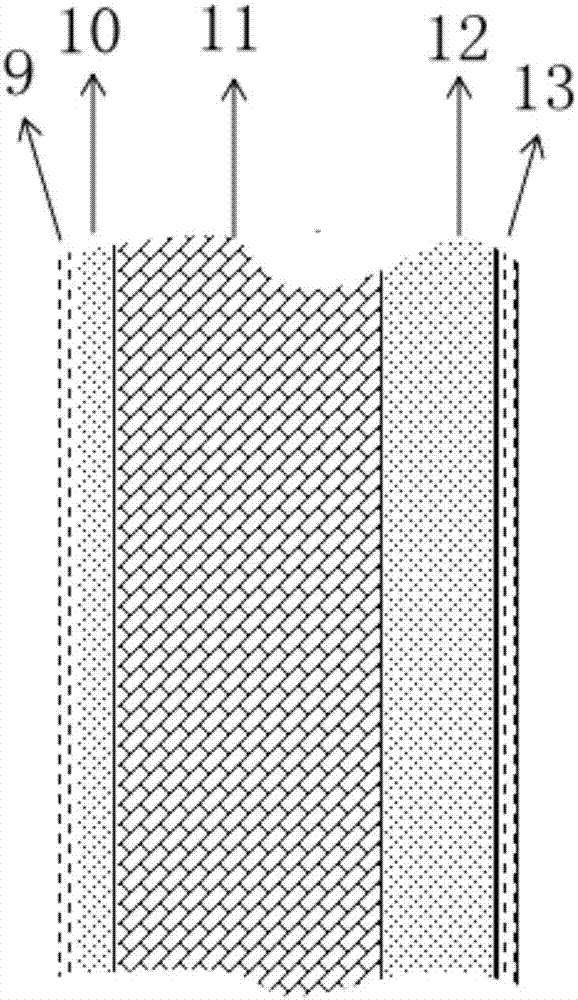

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

[0044] A kind of inorganic mineral fiber spray rock mud, composition material and weight ratio are as follows:

[0045] Inorganic mineral fiber 60%; fiber sepiolite 20%; hydroxypropyl methylcellulose (HPMC) 0.5%; redispersible latex powder 2%; water repellent: 0.5%; Portland cement 10%;

[0046] The inorganic mineral fiber has a melting point of 1200°C and a thermal conductivity of 0.035W / m.k.

[0047] The fiber sepiolite: longitudinal fiber, melting point 1200°C, thermal conductivity: 0.038-0.046W / m.k.

[0048]The hydroxypropyl methylcellulose (HPMC): 80 mesh to 120 mesh, model number: 60YTJ100000 to 60YTJ200000.

[0049] The average particle size (um) of the redispersible latex powder is 85±15.

[0050] The water-repellent agent: fineness: 150 μm; sieve residue ≤ 10%; active substance content: ≥ 65%

[0051] The strength grade of the Portland cement is 425#.

[0052] Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com