A kind of self-compacting steel tube concrete and preparation method thereof

A steel-filled concrete and self-compacting technology, applied in the field of building materials, can solve the problems of increasing the internal water consumption of concrete, the development of concrete strength, the adverse effect of durability, and the low water-to-binder ratio, so as to reduce the internal curing cost and improve the work performance. and mechanical properties, the effect of reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

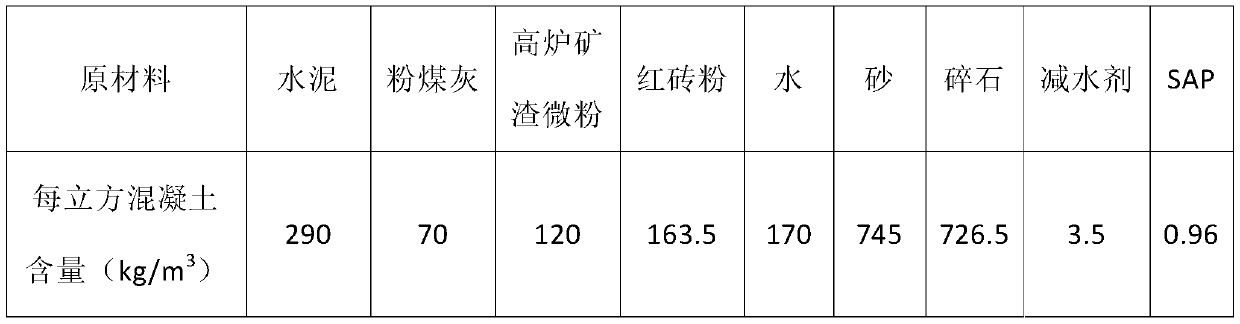

[0020] A kind of C50 self-compacting concrete filled steel tube, its mix ratio is shown in the following table (the dosage of toughening agent is uniformly 0.096kg / m 3 , the following examples will not be repeated):

[0021]

[0022] Mix cement, fly ash, blast furnace slag fine powder, red brick powder, water, sand, water reducer, toughening agent, SAP in proportion to prepare mortar, then add gravel to the mortar, and fully stir to obtain self-compacting steel pipe concrete. The obtained concrete was tested for various properties of the initial and hardened concrete. The curing method was water curing. The performance test results of C50 self-compacting concrete were as follows:

[0023]

Embodiment 2

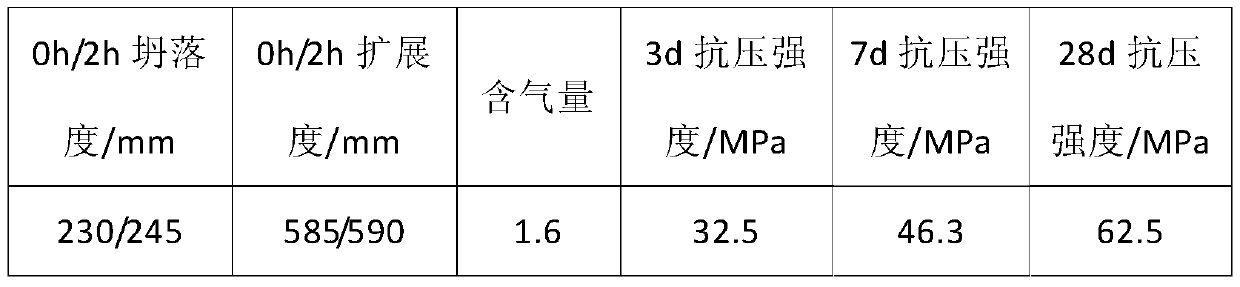

[0025] A C50 self-compacting concrete filled steel tube, its mix ratio is shown in the following table:

[0026]

[0027] Mix cement, fly ash, blast furnace slag fine powder, red brick powder, water, sand, water reducer, toughening agent, SAP in proportion to prepare mortar, then add gravel to the mortar, and fully stir to obtain self-compacting steel pipe concrete. The obtained concrete was tested for various properties of the initial and hardened concrete. The curing method was water curing. The performance test results of C50 self-compacting concrete were as follows:

[0028]

Embodiment 3

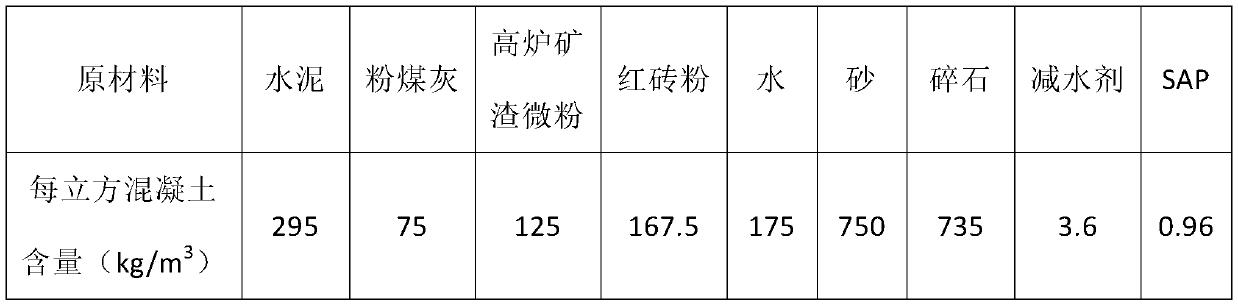

[0030] A C50 self-compacting concrete filled steel tube, its mix ratio is shown in the following table:

[0031]

[0032] Mix cement, fly ash, blast furnace slag fine powder, red brick powder, water, sand, water reducer, toughening agent, SAP in proportion to prepare mortar, then add gravel to the mortar, and fully stir to obtain self-compacting steel pipe concrete. The obtained concrete was tested for various properties of the initial and hardened concrete. The curing method was water curing. The performance test results of C50 self-compacting concrete were as follows:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com