Lower valve and high-precision brake valve

A brake valve, high-precision technology, applied in the direction of brakes, brake components, brake transmissions, etc., can solve the problems of size reduction, achieve extended life, improved braking effect, and are not easy to be scratched and corroded Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

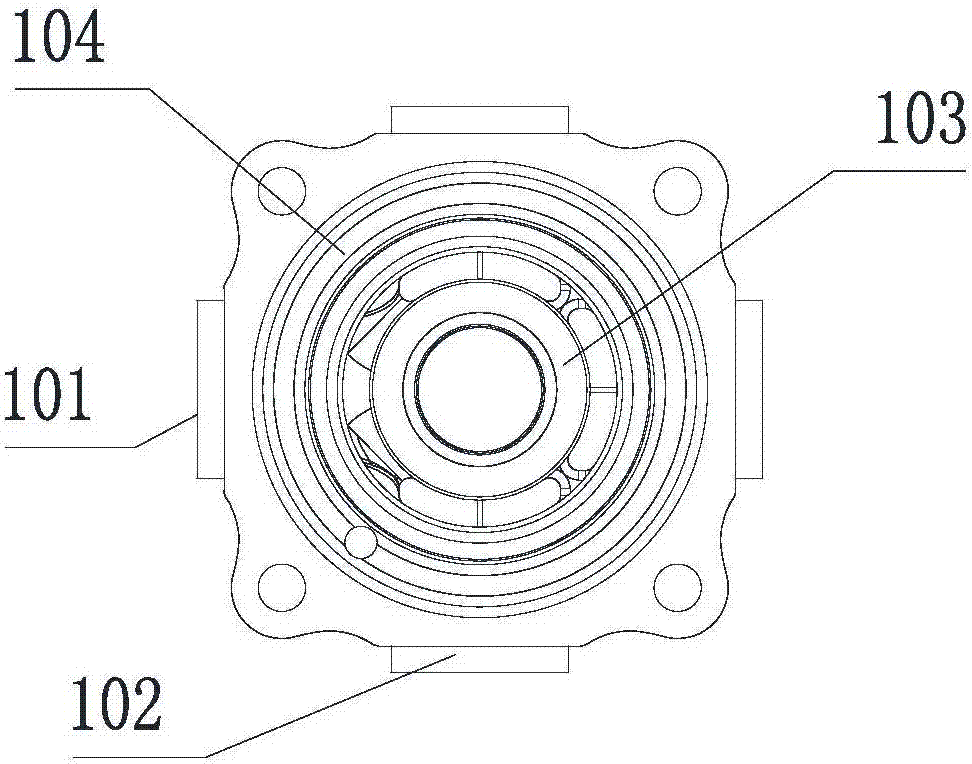

[0040] Such as Figure 1-3 As shown, this embodiment provides a lower valve body, including a lower valve body 1 with an inner cavity and an open top, the lower valve body is provided with a lower valve body air inlet 101 and a lower valve body air outlet 102, The middle part of the lower valve body is provided with an air storage valve 103 for switching the connection state between the air inlet of the lower valve body and the air outlet of the lower valve body. The air valve is closed, the air inlet of the lower valve body is not connected with the air outlet of the lower valve body, and the external force described in the present invention is the braking force.

[0041] Because in the prior art, the spring connected between the lower end of the piston and the lower valve body is arranged on the air passage, the following defects arise:

[0042] 1. Block the air passage connecting the air inlet of the lower valve body and the air outlet of the lower valve body;

[0043] 2....

Embodiment 2

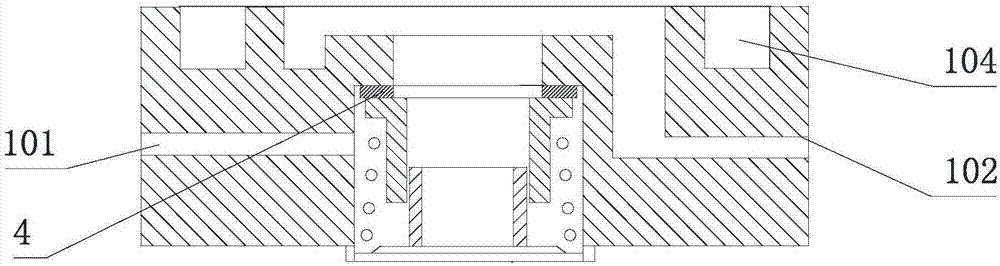

[0052] Such as Figure 4-9 As shown, a high-precision brake valve includes the lower valve body described in Embodiment 1, and also includes an upper valve body 2 with an inner cavity and an opening at the bottom of the inner cavity. The upper valve body and the lower valve body are also It is fixed by bolts and a sealing ring is set to achieve sealing; it also includes a piston 3 arranged in the inner cavity formed by the combination of the lower valve body and the upper valve body; the upper valve body has an air inlet of the upper valve body, and the piston is the second from top to bottom. Piston part 302 and the 3rd piston part 303, wherein, the diameter of the 2nd piston part is greater than the diameter of described 3rd piston part; A sealing ring is arranged on the edge of the upper valve body and snapped into the inner cavity of the upper valve body, the third piston part cooperates with the lower valve body to control the opening and closing of the lower valve body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com