Automatic-held shaft part safety protection frame

A technology for shaft parts and safety protection, applied in the direction of tool storage devices, manufacturing tools, etc., can solve the problems of extrusion damage, inconvenient use, easy deformation, etc., and achieve the effect of saving production sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

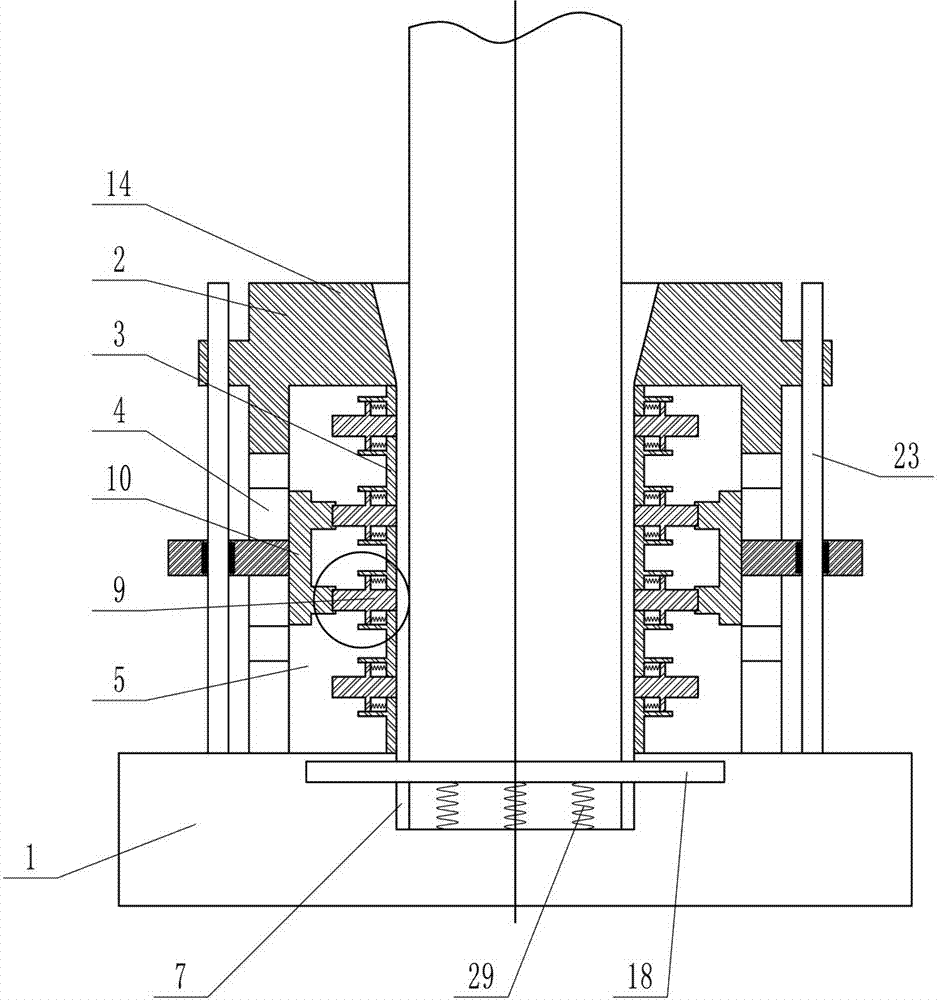

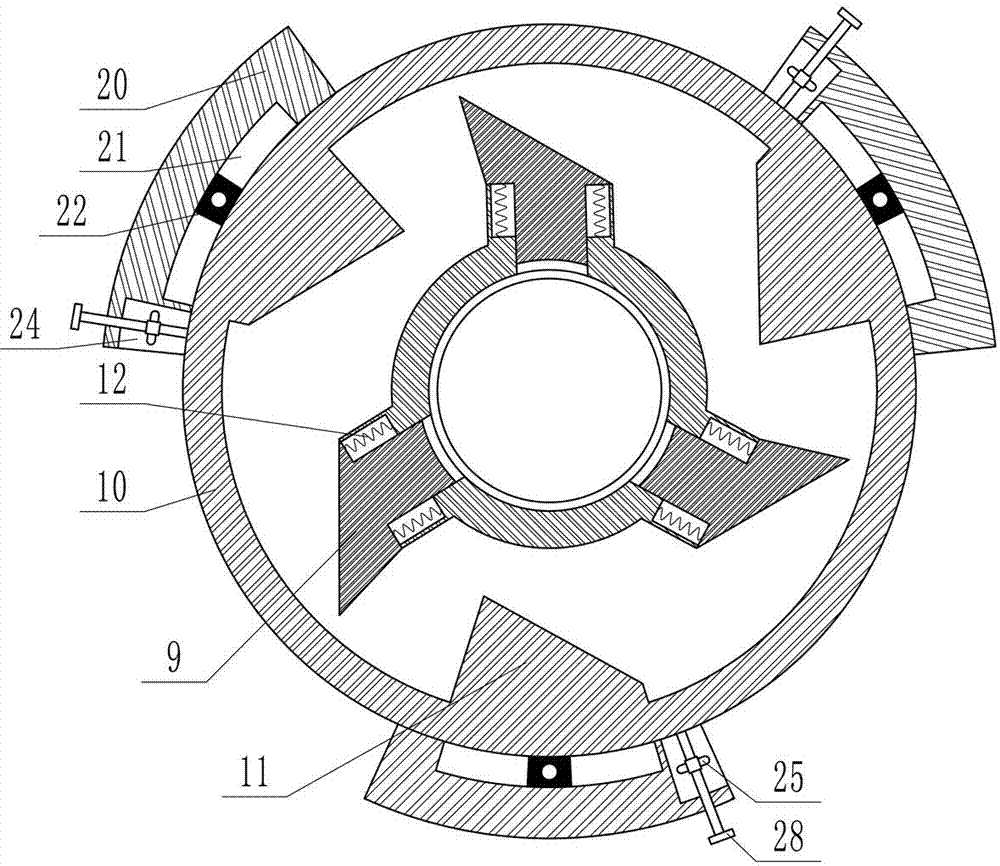

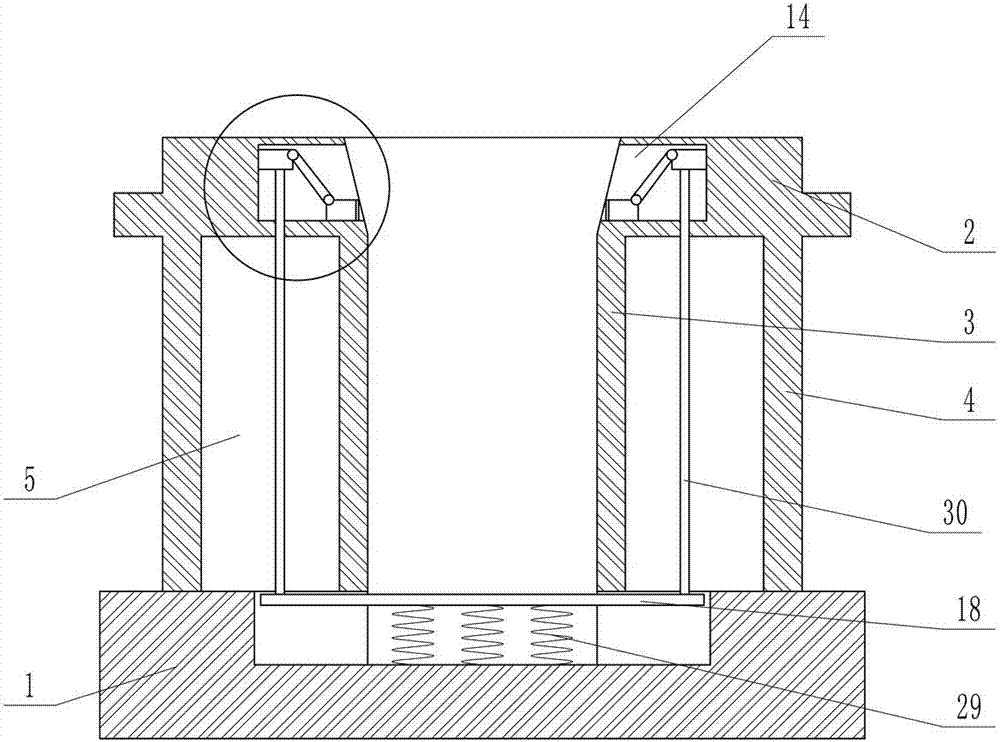

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Depend on Figure 1-10 It can be seen that the present invention includes a base 1, a cylindrical barrel seat 2 is vertically placed on the upper end of the base 1, and the lower part of the barrel seat 2 is an inner and outer two-layer structure composed of an inner sleeve 3 and an outer sleeve 4. An annular cavity 5 is formed between the sleeves 4, a first through hole 6 is opened in the center of the inner sleeve 3, a blind hole 7 concentric with the through hole is opened on the base 1, and a plurality of holes are opened on the side wall of the inner sleeve 3 The first through groove 8, the first through groove 8 is evenly distributed on the circumference of the side wall of the inner sleeve 3, and each first through groove 8 is provided with a pressure block 9 that can slide inside and outside, and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com