Preparing method for spliced combined structure composite metal sheet and composite metal sheet of preparing method

A combined structure and composite metal technology, which is applied to the preparation of composite metal sheets of spliced composite structures and the field of composite metal sheets, can solve the problems of broken interface bonding, composite failure, and instability of the interface stiffness to be bonded, etc., so as to eliminate processing stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

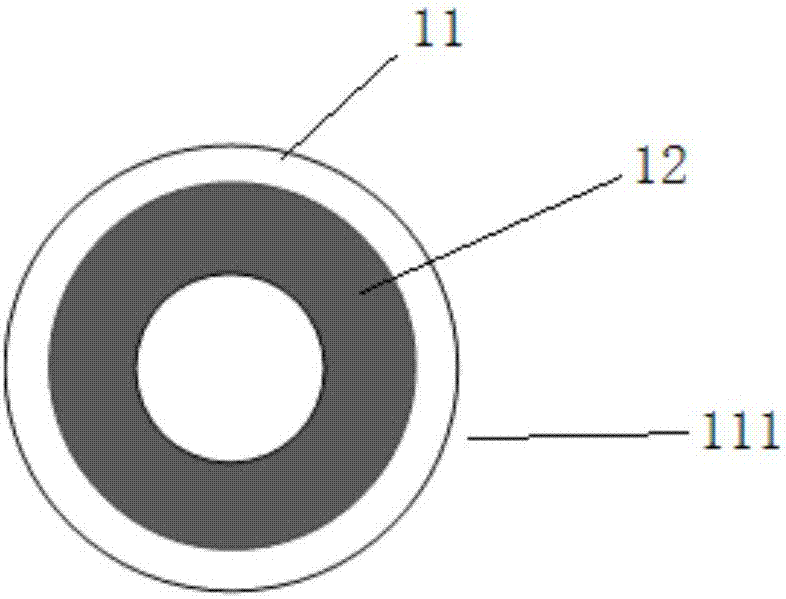

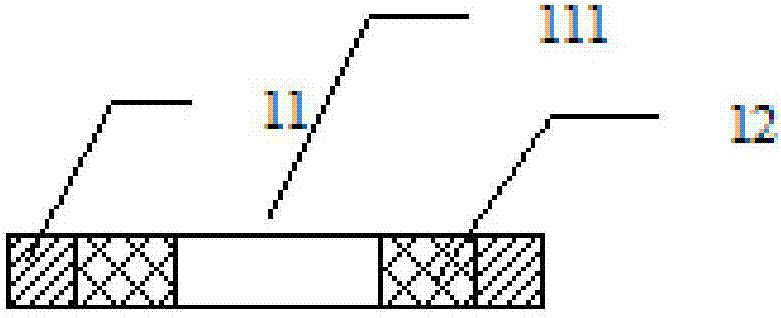

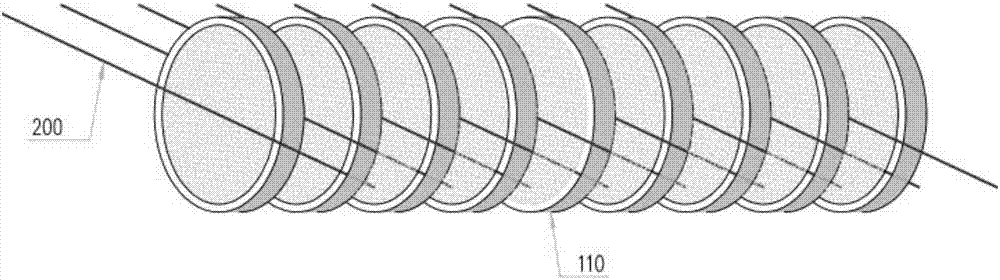

[0040] The ring-shaped composite metal sheet 111 of embodiment 1 sees figure 1 and figure 2 , which is composed of an outer ring of pure aluminum (A1060) metal sheet 11 and an inner ring of pure copper (T2) metal sheet 12. Combining strong physical metallurgical bonding methods, the outer diameter of the aluminum ring metal sheet is Ф12mm, the inner diameter is Ф11mm, and there is a through hole 13 in the middle of the copper ring metal sheet, that is, the outer diameter of the copper ring is Ф11mm, and the inner ring through hole 13 diameter is Ф9mm. The thickness of the entire annular metal sheet and the copper and aluminum metal sheets is 2mm.

[0041] The preparation process of the whole ring-shaped composite metal sheet is as follows:

[0042] S1. The incoming material is Ф13 pure copper rod and Ф9.5 pure aluminum rod for cladding and continuous extrusion. The core material is copper rod and the cladding material is aluminum rod. The TLJ340 continuous extrusion machin...

Embodiment 2

[0048] See Figure 9 , the conductive connecting piece 300 is designed as follows: thickness 1.2mm; total length 200mm (of which C10200 pure copper 301 is 120mm long, 1060 pure aluminum 302 is 80mm long, pure copper and pure aluminum are both 1.2mm and they are joined together on the side where they are in contact combined); width 70mm. This design adopts the technical scheme that copper-aluminum side (rolling) composite strip material is punched into sheet again along the transverse direction of strip material is quite difficult, and the prior art is difficult to obtain. However, by adopting the technical solution disclosed in the present invention, it is possible to obtain a conductive connecting metal sheet with a copper-aluminum spliced connection structure that meets the size and application performance requirements of the originally designed conductive connecting sheet 300 . Proceed as follows:

[0049] S1, the C10200 copper strip with a raw material width of 150mm a...

Embodiment 3

[0055] The specific embodiment is completely consistent with the material composition and structure of the final product of embodiment 1—annular interlocking composite metal sheet.

[0056] Different from Example 1, the S1 step of this example adopts the pre-coating combined drawing method: that is, the uncoiled soft aluminum strip 2.0mm (thickness)*62mm (width) surrounds a pure copper rod with a diameter of Φ20mm, and through the coating On-line cleaning of the welding unit, multiple sets of cold-bending forming dies are gradually rolled into a round tube, and then the CO 2 The continuous laser welding machine continuously welds the longitudinal seam formed by the round tube. After the welding is completed, the unit is equipped with a Φ22mm drawing die, so that the aluminum tube tightly covers the copper rod, preventing air from entering the gap between the copper rod and the aluminum tube to cause oxidation; Then, a Φ22mm aluminum-clad copper rod is subjected to 60% large pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com