Spraying assembly line

A technology of assembly line and water spray head, which is applied in the direction of coating, spray booth, spraying device, etc., can solve the problems of low work efficiency and high manufacturing cost, and achieve the effect of high work efficiency, good spray effect and high appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

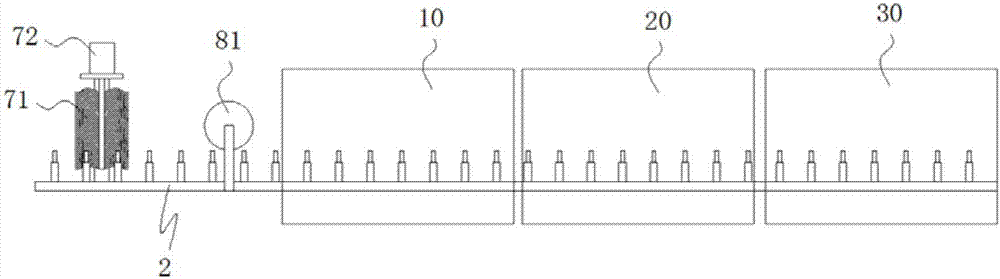

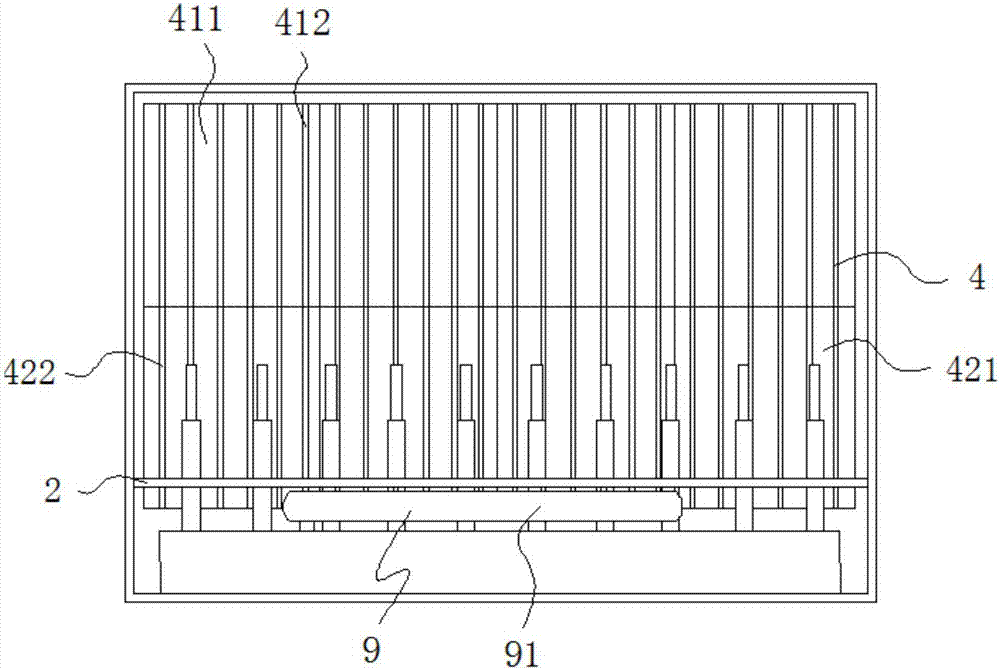

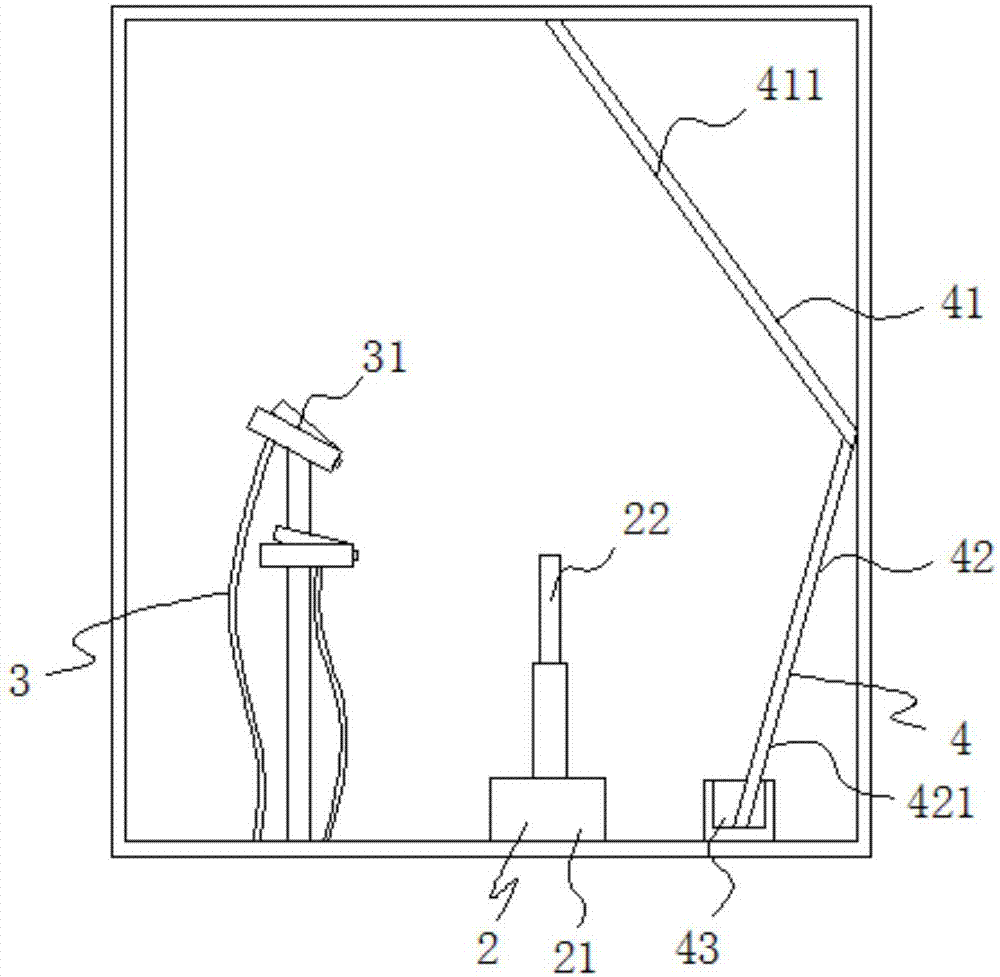

[0022] Such as Figure 1-7 As shown, a spraying assembly line includes a conveying device 2 for conveying materials, a cleaning unit distributed sequentially along the conveying direction of the conveying device, a height adjustment unit, a dust removal unit 10, a spraying unit 20 and a baking unit 30; The conveying device 2 includes a conveyor belt 21, a plurality of supports 22 and a drive structure 9, the supports 22 are distributed along the length direction of the conveyor belt, and the distance between adjacent supports 22 is set to be equal; the conveying The belt 21 can move forward under the drive of the rollers, the specific principle is the prior art, and will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com