Nanometer preparation system method based on supercritical carbon dioxide technology

A carbon dioxide and nano-preparation technology applied in the field of biomedical engineering to achieve high yield, simple operation, mild and controllable preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

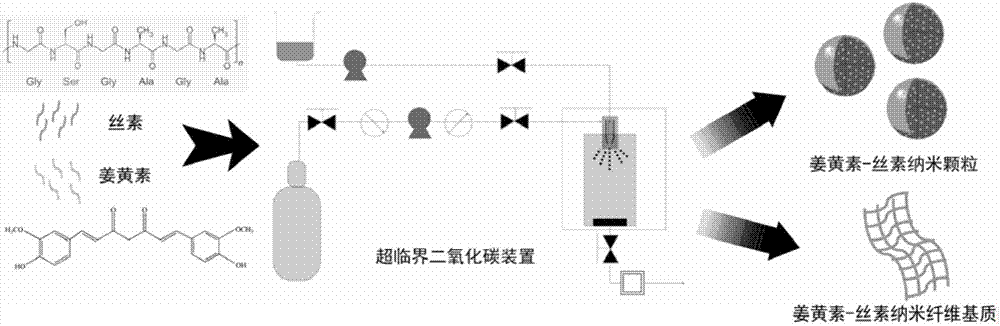

Embodiment 1

[0056] First, a curcumin-silk fibroin solution was prepared, and curcumin was dissolved in hexafluoroisopropanol containing silk fibroin, the ratio of curcumin to silk fibroin was 1:2, and the total concentration of the mixed solution was 0.5%. Attached figure 1 In the supercritical device shown, open the pressure valve to make the pressure in the crystallization tank reach the predetermined supercritical pressure of 10MPa, control the temperature at 35°C, and open the exhaust valve to keep the pressure and temperature constant. Pump the curcumin-silk fibroin solution, and adjust the pump speed to 0.5mL / min. After the sample is pumped, close the injection valve and keep other conditions unchanged (pressure, temperature, etc.) for at least 30 minutes to completely remove the solvent and dry the sample. Finally close the intake valve, and the CO in the crystallization kettle 2 After the gas was completely evacuated, the crystallization kettle was opened and samples were collec...

Embodiment 2

[0058] The preparation process is similar to Example 1. First, a curcumin-silk fibroin solution was prepared, and curcumin was dissolved in hexafluoroisopropanol containing silk fibroin, the ratio of curcumin to silk fibroin was 1:2, and the total concentration of the mixed solution was 0.5%. Attached figure 1 In the supercritical device shown, open the pressure valve to make the pressure in the crystallization tank reach the predetermined supercritical pressure of 20MPa, control the temperature at 35°C, and open the exhaust valve to keep the pressure and temperature constant. Pump the curcumin-silk fibroin solution, and adjust the pump speed to 0.5mL / min. After the sample is pumped, close the injection valve and keep other conditions unchanged (pressure, temperature, etc.) for at least 30 minutes to completely remove the solvent and dry the sample. Finally close the intake valve, and the CO in the crystallization kettle 2 After the gas was completely evacuated, the crystal...

Embodiment 3

[0060] First, a curcumin-silk fibroin solution was prepared, and curcumin was dissolved in hexafluoroisopropanol containing silk fibroin, the ratio of curcumin to silk fibroin was 1:9, and the total concentration of the mixed solution was 4%. Attached figure 1 In the supercritical device shown, open the pressure valve to make the pressure in the crystallization tank reach the predetermined supercritical pressure of 20MPa, control the temperature at 35°C, and open the exhaust valve to keep the pressure and temperature constant. Pump the curcumin-silk fibroin solution, and adjust the pump speed to 8mL / min. After the sample is pumped, close the injection valve and keep other conditions unchanged (pressure, temperature, etc.) for at least 30 minutes to completely remove the solvent and dry the sample. Finally close the intake valve, and the CO in the crystallization kettle 2 After the gas was completely evacuated, the crystallization kettle was opened and samples were collected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com