Textile-based enhanced degradable tube cavity support and preparation method and application thereof

An enhanced, textile-based technology, applied in the field of textile-based enhanced degradable luminal stents and its preparation, can solve the problems of low shear stress on the vessel wall, poor stent morphology and mechanical properties, smooth muscle cell activation, etc., and achieve improved Radial support, effective fixation, and the effect of preventing loose edges and off-lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

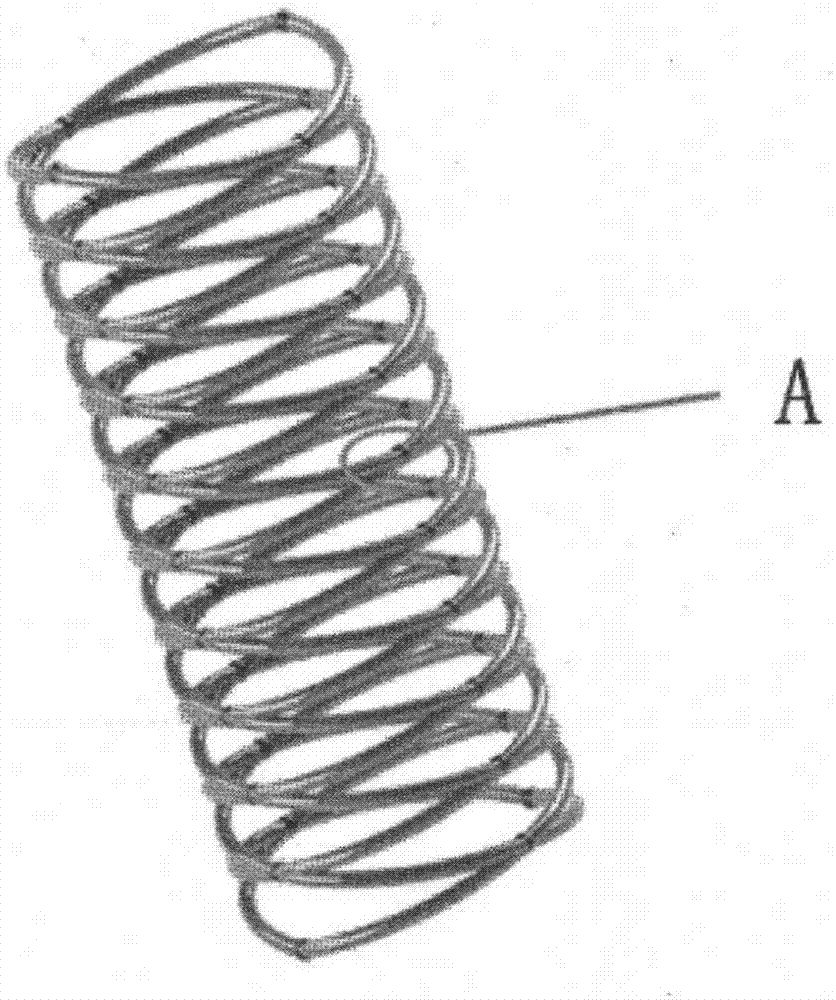

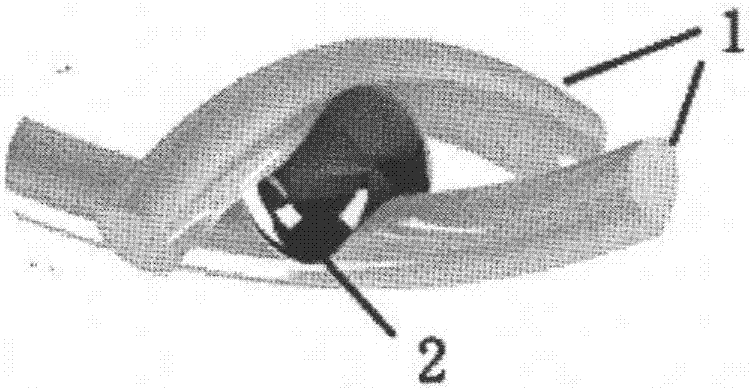

[0035] Such as figure 1 and figure 2As shown, a textile-based reinforced degradable luminal stent includes a hollow tubular fabric formed by two-dimensional and three-dimensional braiding of degradable polymer threads as braided threads 1, and two sets of braided threads 1 Introduce the axial thread 2, the axial thread 2 does not participate in the weaving, the axial thread 2 is melted through the heat treatment process, and the interweaving points of the two groups of degradable polymer threads are bonded and fixed by the molten axial thread 2, thereby obtaining a shape-stable Textile-based reinforced degradable luminal stent.

[0036] The preparation method of the textile-based reinforced degradable endoluminal stent is as follows:

[0037] Step 1: Make bobbins of two sets of braiding threads required for interweaving and place them on the yarn carrier of the 48-spindle two-dimensional spindle knitting machine; lead the axial threads through the through hole in the center...

Embodiment 2

[0041] Such as figure 1 and figure 2 As shown, a textile-based reinforced degradable luminal stent includes a hollow tubular fabric formed by two-dimensional and three-dimensional braiding of degradable polymer threads as braided threads 1, and two sets of braided threads 1 Introduce the axial thread 2, the axial thread 2 does not participate in the weaving, the axial thread 2 is melted through the heat treatment process, and the interweaving points of the two groups of degradable polymer threads are bonded and fixed by the molten axial thread 2, thereby obtaining a shape-stable Textile-based reinforced degradable luminal stent.

[0042] The preparation method of the textile-based reinforced degradable endoluminal stent is as follows:

[0043] Step 1: Make bobbins of the two sets of braiding threads required for interweaving and place them on the yarn carrier of the 32-spindle two-dimensional spindle knitting machine; lead the axial threads through the through hole in the c...

Embodiment 3

[0047] Such as figure 1 and figure 2 As shown, a textile-based reinforced degradable luminal stent includes a hollow tubular fabric formed by two-dimensional and three-dimensional braiding of degradable polymer threads as braided threads 1, and two sets of braided threads 1 Introduce the axial thread 2, the axial thread 2 does not participate in the weaving, the axial thread 2 is melted through the heat treatment process, and the interweaving points of the two groups of degradable polymer threads are bonded and fixed by the molten axial thread 2, thereby obtaining a shape-stable Textile-based reinforced degradable luminal stent.

[0048] The preparation method of the textile-based reinforced degradable endoluminal stent is as follows:

[0049] Step 1: Make bobbins of two sets of braiding threads required for interweaving and place them on the yarn carrier of the 48-spindle two-dimensional spindle knitting machine; lead the axial threads through the through hole in the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com