Tobacco flavor, preparation method thereof and application thereof in cigarettes

A technology for flavoring and cigarettes used in tobacco, applied in the field of tobacco processing, to achieve the effects of simple preparation method, reducing irritation, and improving sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

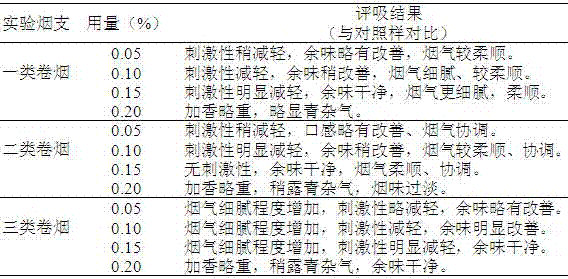

Examples

Embodiment 1

[0017] A preparation method of tobacco spices, specifically:

[0018] Put the ebony and orange peels in a constant temperature vacuum oven at 60°C to fully dry them, then cool them naturally in the oven, and take them out. According to the mass ratio of 1:1, 200g of dark plum and orange peel were weighed, ground and pulverized, added to a round bottom flask, and then 750mL of ethanol with a volume concentration of 95% was added, heated and refluxed in a water bath for extraction for 8h. After the reflux extraction is completed, filter while it is hot. After the filtrate is cooled, it is concentrated under reduced pressure and evaporated to remove the ethanol solvent to obtain a reddish-brown viscous extract, which is the tobacco flavor (with great sweetness and sourness).

Embodiment 2

[0020] A preparation method of tobacco spices, specifically:

[0021] Put the ebony and orange peels in a constant temperature vacuum oven at 60°C to fully dry them, then cool them naturally in the oven, and take them out. According to the mass ratio of 2:1, 120 g of ebony and orange peel were weighed, ground and pulverized, added to a round bottom flask, and then added: 500 mL of ethanol with a volume concentration of 95%, heated and refluxed in a water bath for 4 h. After the reflux extraction is completed, filter while it is hot. After the filtrate is cooled, it is concentrated under reduced pressure and evaporated to remove the ethanol solvent to obtain a reddish-brown viscous extract, which is the tobacco flavor (with great sweetness and sourness).

Embodiment 3

[0023] A preparation method of tobacco spices, specifically:

[0024] Put the ebony and orange peels in a constant temperature vacuum oven at 60°C to fully dry them, then cool them naturally in the oven, and take them out. According to the mass ratio of 3:1, 200g of dark plum and orange peel were weighed, ground and pulverized, added to a round bottom flask, and then 900mL of ethanol with a volume concentration of 90% was added, heated and refluxed in a water bath for extraction for 10h. After the reflux extraction is completed, filter while it is hot. After the filtrate is cooled, it is concentrated under reduced pressure and evaporated to remove the ethanol solvent to obtain a reddish-brown viscous extract, which is the tobacco flavor (with great sweetness and sourness).

[0025] Composition analysis of the tobacco spices (extract) prepared in the above examples: Agilent7890A-5975C GC / MS (Agilent Technologies Co., Ltd., USA) was selected, and the analysis found that the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com